Step-down gear unit

A technology for reduction gears and transmission systems, applied in gear transmissions, belts/chains/gears, mechanical equipment, etc., can solve problems such as high manufacturing costs, achieve economical production measures, reduce friction, and achieve the effects of small and compact structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

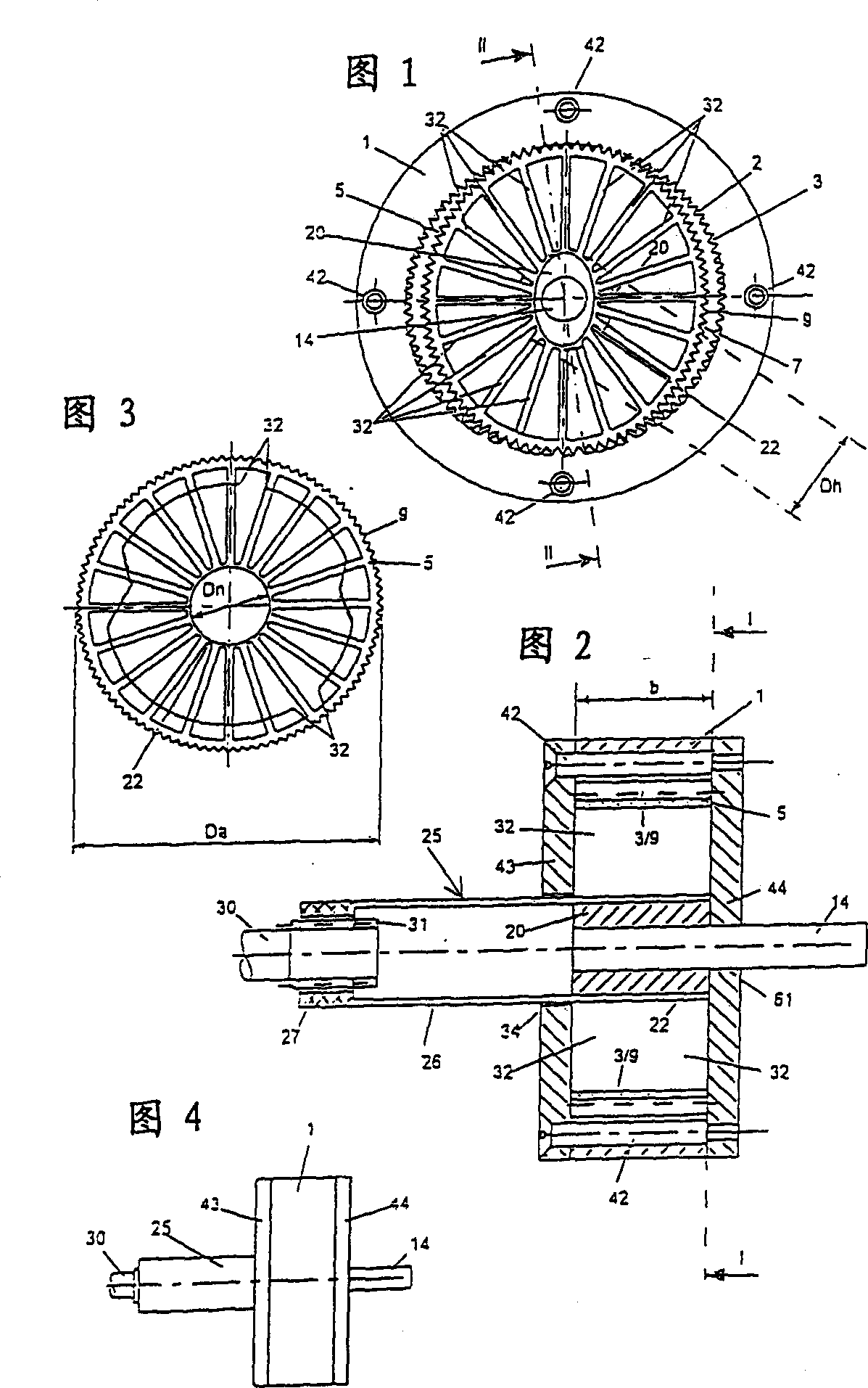

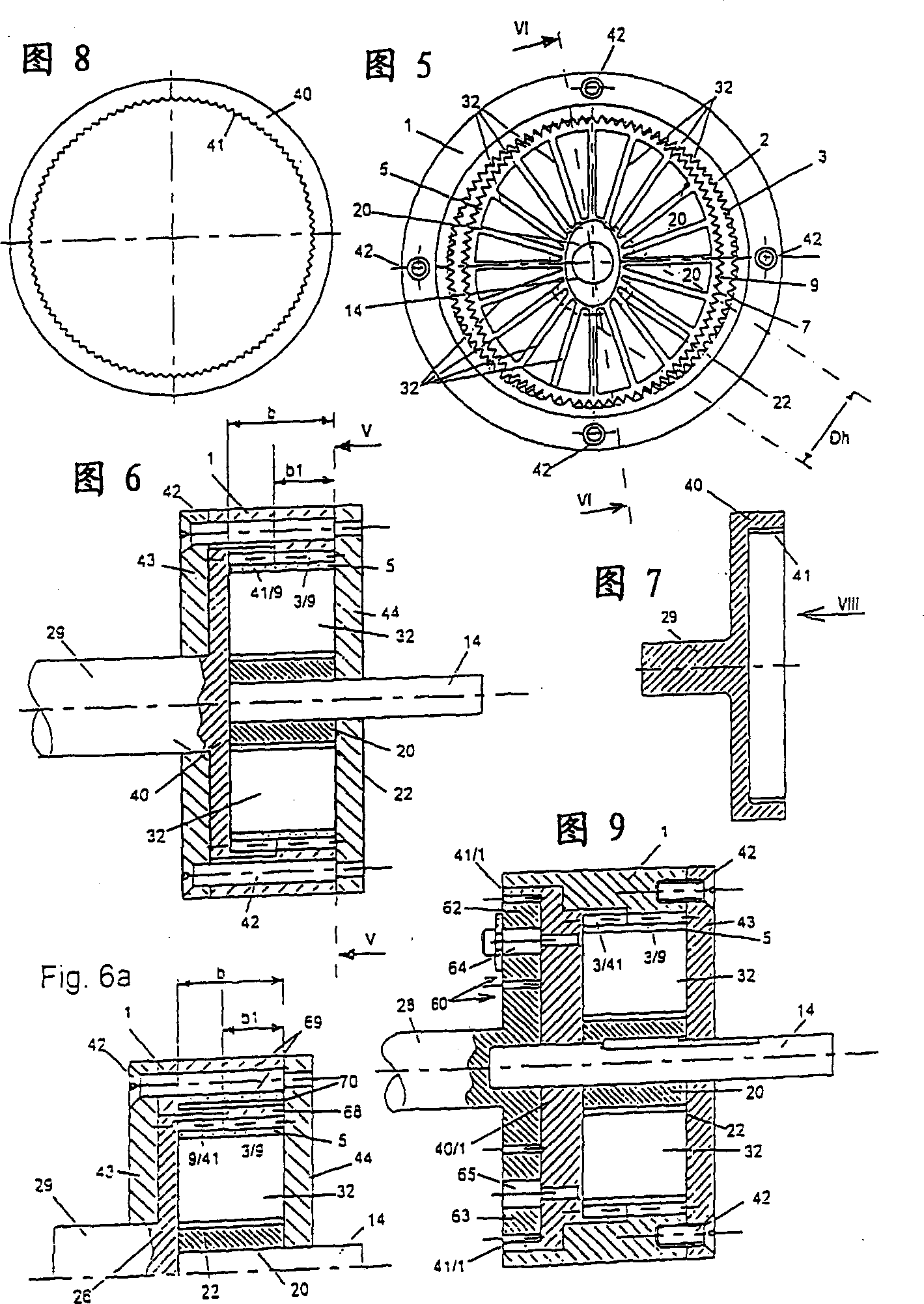

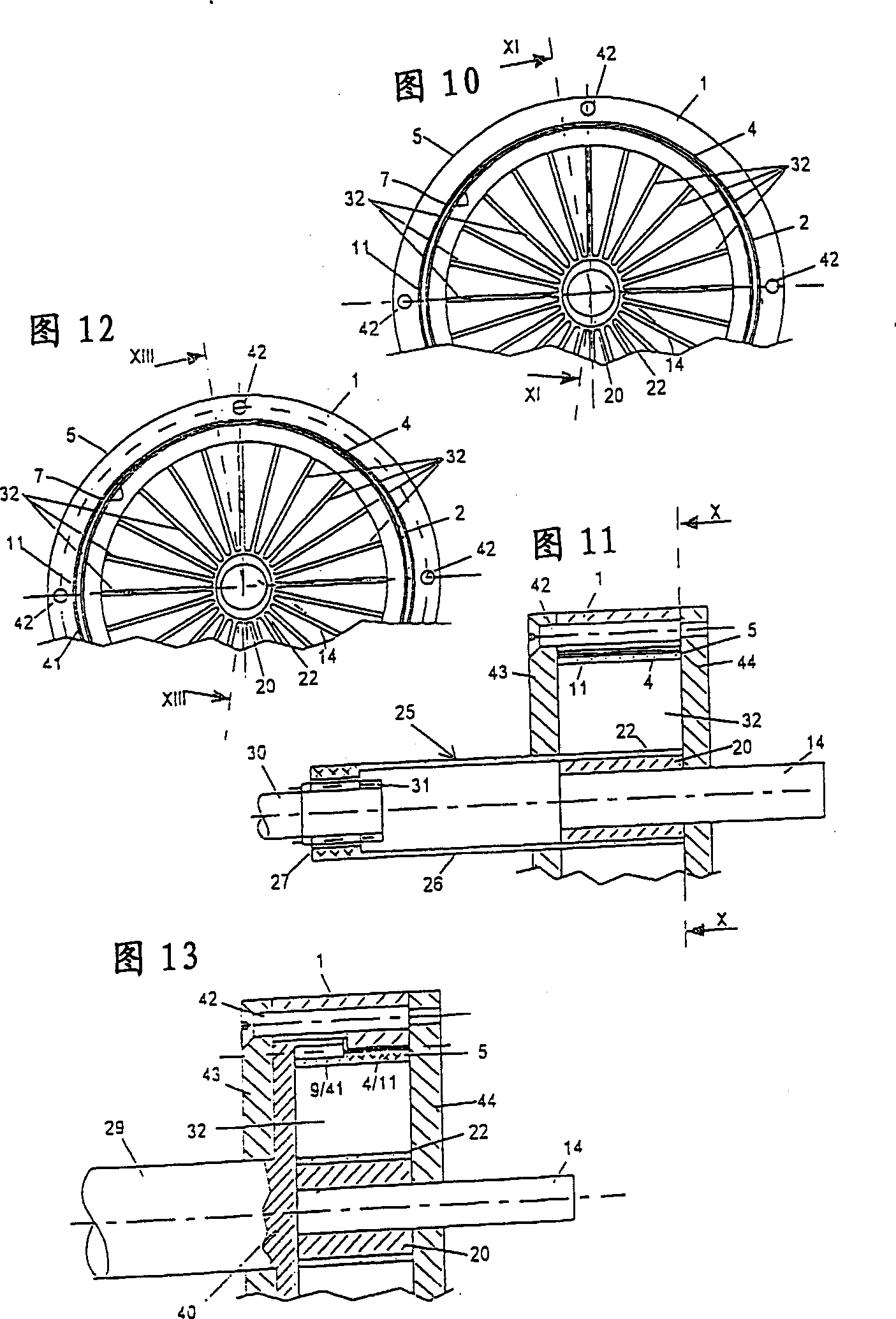

[0077] Various embodiments of the reduction gear system will be described below with reference to the figures presented above, the essential parts of which are in each case: a circular bearing ring 1 with a circular inner bearing surface 2, a circular bearing ring 1 with an outer peripheral surface 7 rolling sleeve 5, and an oval or triangular drive core 20 or 20 / 1.

[0078] In the exemplary embodiment of Figures 1, 2 and 3, the cylindrical support ring 1 is provided with internal teeth 3 which extend across its entire width b. As a fixed gear part, the above-mentioned support ring 1 is non-rotatably connected to any mechanism carrier not shown in the figures or the like. End walls 43 and 44 , which are connected to each other or to the support ring 1 with axial screws 42 , are respectively arranged on their two side faces. In the central opening 61 of the end wall 44 is mounted a drive shaft 14 for rotation, which is connected, for example, to a drive motor and designed to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com