Preparation method of heteroatom-doped graphene

A heterogeneous atom, graphene technology, applied in graphene, nano-carbon and other directions, can solve the problems of complex process, high cost, environmental pollution, etc., and achieve the effect of simplifying operation steps, reducing preparation cost, and enriching active sites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Dissolve 10g of urea and 1g of citric acid in a mixed solution of 100mL of alcohol and 100mL of deionization, stir in a water bath at 85°C until it reaches a sol-gel state, and dry the resulting sol-gel in an oven at 100°C for 8 hours to obtain a precursor. The obtained precursor was loaded into a quartz boat, heated to 850° C. in a tube furnace for 5 h, and then lowered to room temperature to obtain nitrogen-doped graphene.

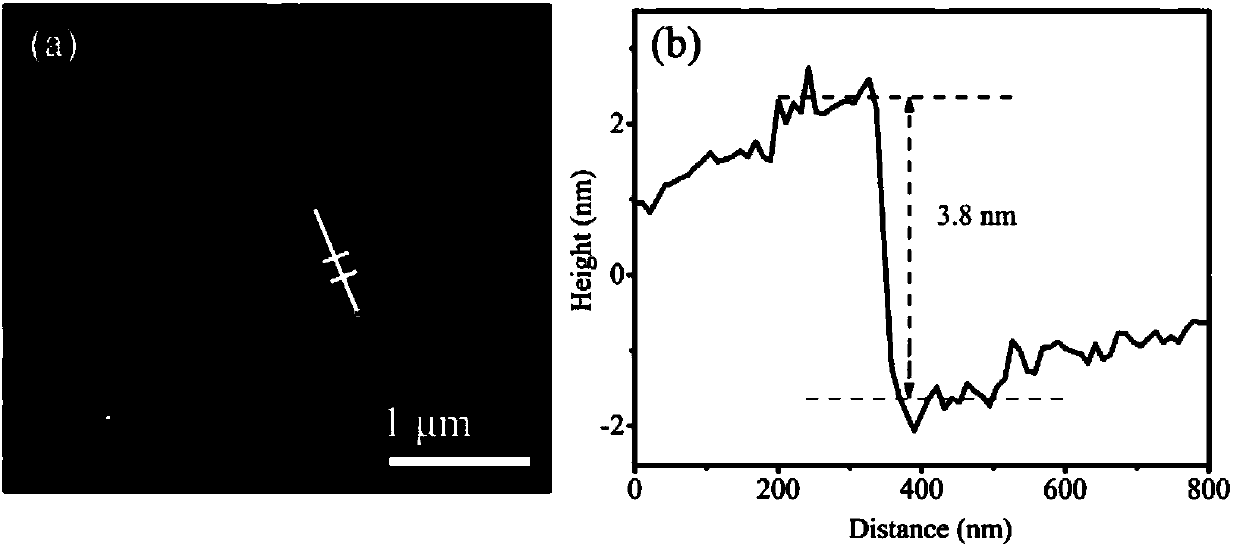

[0027] From scanning electron microscope photographs (see figure 1 a) It can be seen that the prepared nitrogen-doped graphene is in a uniform sheet shape.

[0028] figure 1 b is a transmission electron microscope photo of nitrogen-doped graphene. It can be seen that the color of each part of the graphene sheet is uniform, and it is tulle-like. figure 2 An atomic force microscope image of nitrogen-doped graphene. As can be seen from the figure, the height of nitrogen-doped graphene is about 3nm.

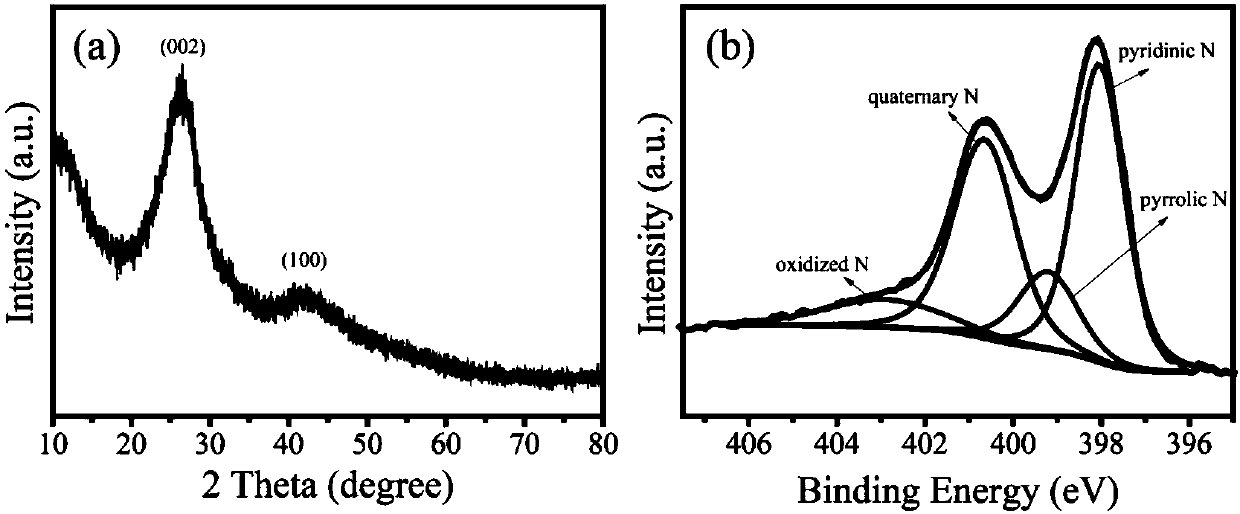

[0029] From the XRD figure of product (see ...

Embodiment 2

[0031] Dissolve 5 g of urea and 1 g of glucose in a mixed solution of 150 mL of alcohol and 100 mL of deionization, stir in a water bath at 85 °C until it reaches a sol-gel state, and dry the resulting sol-gel in an oven at 100 °C for 8 hours to obtain a precursor. The obtained precursor was loaded into a quartz boat, heated to 750°C in a tube furnace for 5 hours, and cooled to room temperature to obtain nitrogen-doped graphene. The nitrogen-doped graphene obtained has similar morphology to the nitrogen-doped graphene obtained in Example 1.

Embodiment 3

[0033] Dissolve 10g of urea, 1g of citric acid and 5g of thiourea in a mixed solution of 100mL of alcohol and 100mL of deionization, stir in a water bath at 85°C until it is in a sol-gel state, and dry the resulting sol-gel in an oven at 100°C for 8 hours to obtain a precursor . The obtained precursor was loaded into a quartz boat, heated to 1200 °C in a tube furnace for 2 h, and then lowered to room temperature to obtain nitrogen-sulfur co-doped graphene. The obtained nitrogen-sulfur co-doped graphene has a similar tulle-like morphology to the nitrogen-doped graphene in Example 1. Figure 4 The XRD spectrum and XPS general spectrum of nitrogen-sulfur co-doped graphene show the successful doping of S. By analysis, the atomic percentages of doped N and S are 20.52at% and 3.51at%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com