Method for preparing nanometer titanium dioxide super-hydrophobic film

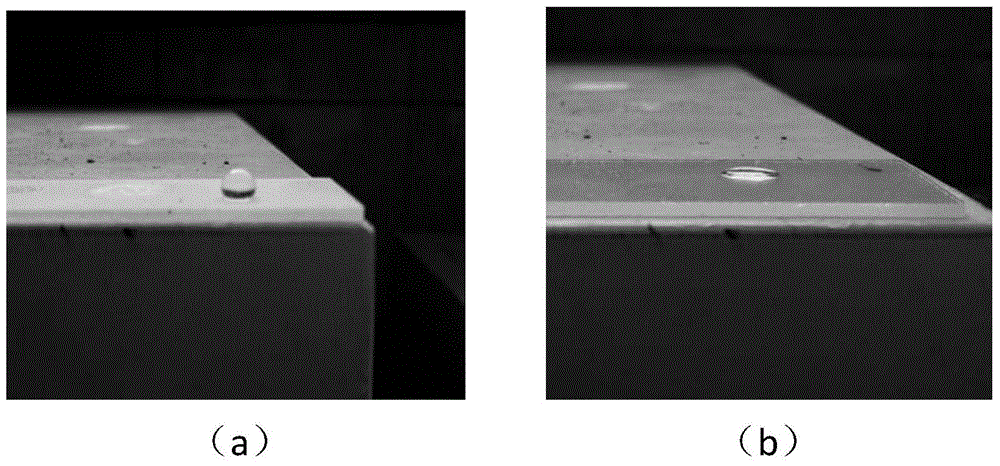

A nano-titanium dioxide and super-hydrophobic technology is applied in the field of preparation of super-hydrophobic films, which can solve the problems of difficult and large-scale manufacturing, harsh experimental conditions, and high manufacturing costs, and achieves high stability, good acid and alkali resistance, and low preparation costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] A preparation method of nano titanium dioxide superhydrophobic film, the steps are as follows:

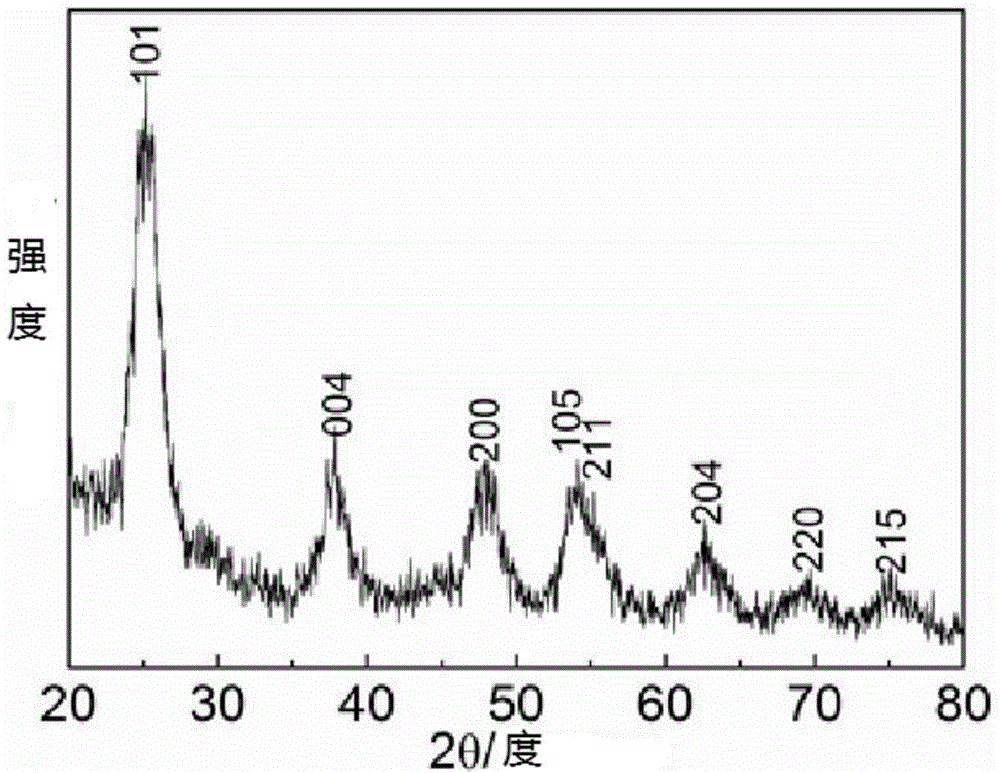

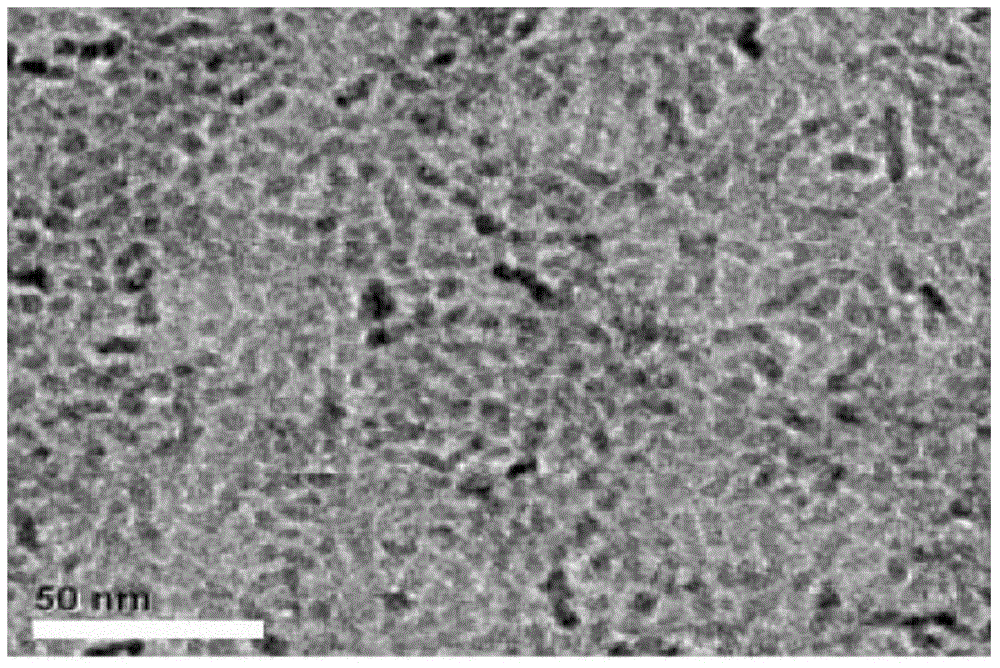

[0025] 1. Preparation of hydrophobic nano-titanium dioxide: Hydrothermal method is used to prepare nano-titanium dioxide. Based on hydrolysis reaction, titanium tetra-n-propoxide that undergoes hydrolysis reaction under natural conditions is selected as the titanium source, and the crystal form is obtained by controlling the reaction conditions. Good nano-titanium dioxide is used to prepare composite materials, the steps are as follows:

[0026] 1) Inject 20mL of ultrapure water and 0.2mL of tert-butylamine into the lining of a polytetrafluoroethylene reactor successively to obtain an aqueous phase; mix 20mL, 5mL of oleic acid and 0.35mL of titanium tetra-n-propoxide evenly to obtain an oil phase; The oil phase is introduced into the lining of the polytetrafluoroethylene reactor, and mixed with the water phase to obtain a mixed solution;

[0027] 2) Put the polytetrafluoroe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com