Nano microcapsule type dry garment piece, and preparation method and application thereof

A technology of nano-microcapsules and dry clothes tablets, which is applied in the fields of textiles, papermaking, and fiber treatment, and can solve the problems of complex use methods and few researches on antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

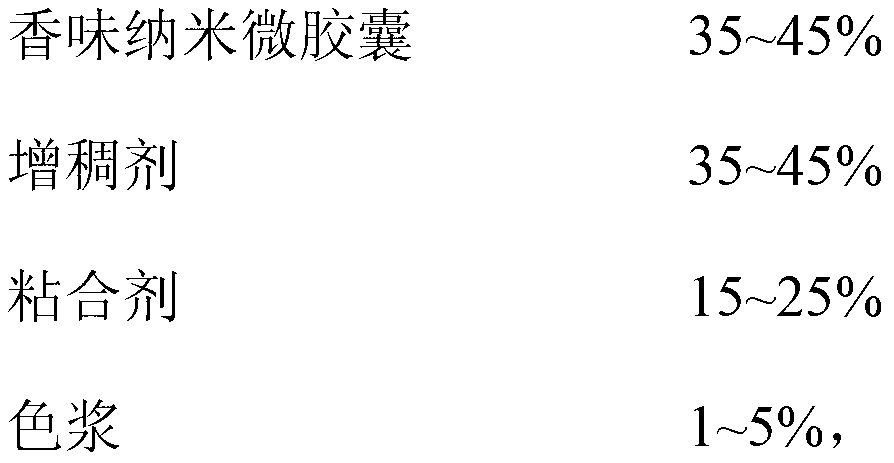

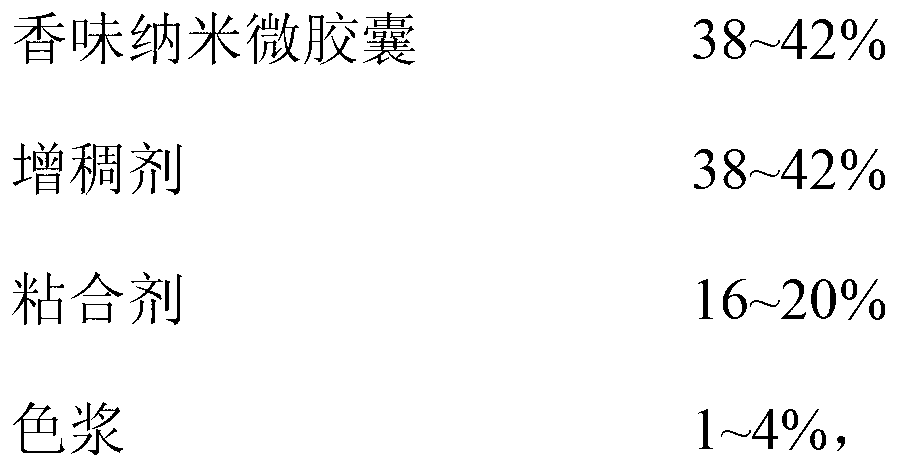

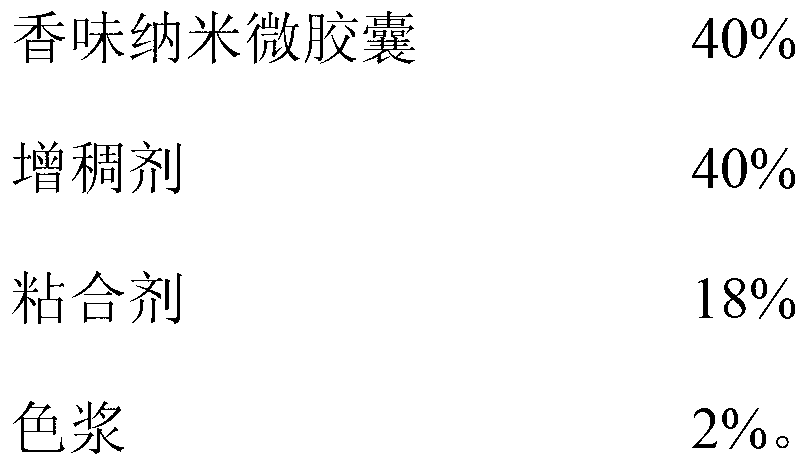

[0068] A method for preparing a nano-microcapsule drying tablet, the method comprising the steps of:

[0069] Preparation of fragrance microcapsule finishing agent: In the glue machine, add hydroxypropyl methylcellulose and lavender essence microcapsules according to the formula, stir evenly, then add polyacrylic resin, color paste, stir well and set aside;

[0070] The polyester non-woven fabric is mounted on a multi-functional coating combined machine, and the polyester non-woven fabric is glued by a scraper-type gluing method, so that the fragrance microcapsule finishing agent is coated on the polyester non-woven fabric;

[0071] The glued polyester non-woven fabric is sent to an oven for drying. The temperature of the oven increases from low to high from the cloth inlet, between 50°C and 100°C. The oven has 6 sections and a total of 18 meters;

[0072] The dried polyester non-woven fabric is rolled up, then cut by a slitting machine on the rack, and then packed into boxes....

Embodiment 2

[0080] A method for preparing a nano-microcapsule drying tablet, the method comprising the steps of:

[0081] Preparation of fragrance microcapsule finishing agent: In the glue machine, add diatomaceous earth (thickener) and peppermint essence microcapsules according to the formula, stir evenly, then add polyacrylic resin (adhesive), color paste, stir until uniform use;

[0082] Put the nylon non-woven fabric on the multi-functional coating combined machine, and use the scraper type glue coating method to glue the nylon non-woven fabric, so that the fragrance microcapsule finishing agent is coated on the nylon non-woven fabric;

[0083] The glued nylon non-woven fabric is sent to the oven for drying. The temperature of the oven increases from low to high from the cloth inlet, between 50°C and 100°C. The oven has 6 sections and a total of 18 meters;

[0084] The dried nylon non-woven fabric is rolled up, then cut by a slitter on the shelf, and then packed into boxes.

[0085...

Embodiment 3

[0090] A method for preparing a nano-microcapsule drying tablet, the method comprising the steps of:

[0091] Preparation of fragrance microcapsule finishing agent: In the glue machine, add sodium alginate (thickener) and strawberry essence microcapsules according to the formula, stir well, then add polyacrylic resin (adhesive), color paste, stir well use;

[0092] The acrylic non-woven fabric is mounted on a multi-functional coating machine, and the acrylic non-woven fabric is glued by using a scraper-type gluing method, so that the fragrance microcapsule finishing agent is coated on the acrylic non-woven fabric;

[0093] The glued acrylic non-woven fabric is sent to an oven for drying. The temperature of the oven increases from low to high from the cloth inlet, and gradually increases between 50°C and 100°C. The oven has 6 sections and a total of 18 meters;

[0094] The dried acrylic non-woven fabric is rolled up, then cut by a slitter on the shelf, and then packed into bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com