Nanometer titanium dioxide powder for flue gas deodorization/denitration catalyst and preparation method and application thereof

A nano-titanium dioxide and catalyst technology, applied in the field of nano-titanium dioxide powder and its preparation, can solve the problems of unevenness, high energy consumption, large particle distribution, etc., and achieve good activity and stability, stable specific surface area, and small particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Preparation of metatitanic acid slurry

[0035] Deploy 50L titanyl sulfate or titanium sulfate hydrolyzate, which meets the following indicators: acid-titanium ratio mH 2 SO 4 / mTiO 2 2.10, iron-titanium ratio mFe / mTiO 2 is 0.4, the initial titanium concentration TiO 2 It is 1.95mol / L. Use a microwave with a power of 210W to heat and hydrolyze titanyl sulfate or titanium sulfate under the condition of 90 degrees and 1 hour. The obtained metatitanic acid is filtered and washed to < 100ppm of alkali metal ions and other heavy ions. Then add deionized water and beat to form a 30% metatitanic acid slurry.

[0036] 2. Hydrothermal synthesis

[0037] Take 50L of the above-mentioned metatitanic acid slurry, add 15% ammonia water to adjust the pH value of the slurry to 10, heat it with 210W microwave at 50°C and stir for 1 hour to fully disperse the slurry.

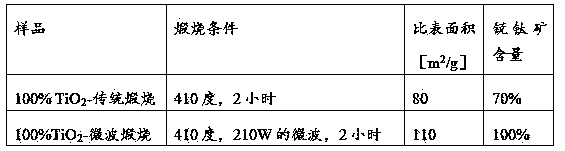

[0038] 3. Calcination

[0039] After the slurry in the above step 2 was sent to a membrane filter press for ...

Embodiment 2

[0041] The preparation of the metatitanic acid slurry was the same as that in Example 1, adding a weighed 8.3Kg of silica sol with a mass fraction of 20% in the metatitanic acid slurry of 50L, and then adding 15% ammonia water to adjust the pH of the slurry The value is 10, 210W microwave heating at 50 degrees and stirring for 1 hour to fully disperse the slurry. After the slurry is sent into a diaphragm filter press for pressure filtration, it is sent into a 210W microwave oven for drying at 110 degrees for 2 hours. The solid obtained by drying was sintered at a temperature of 500 degrees with a microwave of 210W for 2 hours, and then pulverized to obtain a catalyst 10% SiO 2 -90% TiO 2 Composite nano titanium dioxide powder.

Embodiment 3

[0043] The preparation of the metatitanic acid slurry is the same as that in Example 1. Add a weighed 1.87Kg of ammonium paratungstate APT to the 50L metatitanic acid slurry, then add 15% ammonia water to adjust the pH value of the slurry to 10, and a microwave oven of 210W Heat at 50°C and stir for 1 hour to fully disperse the slurry. After the slurry is sent into a diaphragm filter press for pressure filtration, it is sent into a 210W microwave oven for drying at 110 degrees for 2 hours. The solid obtained by drying was sintered at a temperature of 560 degrees with a microwave of 210W for 2 hours, and then pulverized to obtain a catalyst 10% WO 3 -90%TiO 2 Composite nano titanium dioxide powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com