A kind of preparation method of trimanganese tetraoxide

A technology of manganese tetroxide and equipment, applied in manganese oxide/manganese hydroxide and other directions, can solve the problems of complicated operation, low temperature and energy consumption, low production cost, etc., and achieves lower reaction temperature, easy process control, and reaction process. thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

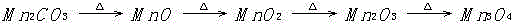

Method used

Image

Examples

Embodiment 1

[0017] Embodiment one: get the manganese carbonate (its water content is 5%) of 500kg and mix evenly with the starch (carbon source) of 50kg, then it is put into continuous microwave steel belt kiln and carry out microwave heating, control its heating rate to be 10 ℃ / min, and the temperature is controlled at 700°C for sintering, and the holding time of sintering is controlled for about 60 minutes. After cooling, trimanganese tetraoxide is obtained, and then the trimanganese tetraoxide is wet-milled to 1000 mesh, and obtained through testing. The manganese content of the product is 71.3%, the unit energy consumption is 4500 degrees / ton, and the specific surface area is 7.8m 2 / g, and it is pure trimanganese tetraoxide after XRD analysis.

[0018] In the HG / T2835-1997 standard, the quality standard of trimanganese tetraoxide is stipulated, see the table below.

[0019] Indicator name Superior product First grade Qualified product Manganese content%≥ 71 70 ...

Embodiment 2

[0023] Embodiment two: get the manganese carbonate of 1kg (its water content is 5%) and the starch (carbon source) of 0.1kg is evenly mixed, then it is put into batch type microwave test furnace and carries out microwave heating, controls its heating rate to be 20 ℃ / min, and the temperature is controlled at 700°C, the holding time of sintering is controlled for about 60 minutes, and then trimanganese tetraoxide is obtained after cooling, and then the trimanganese tetraoxide is wet-milled to 1000 mesh, and the product manganese is obtained after testing The content is 71.5%, the unit energy consumption is 5000 degrees / ton, and the specific surface area is 7.5m 2 / g, and it is pure trimanganese tetraoxide by XRD analysis, and its specific indicators are shown in the table below.

[0024] Indicator name Trimanganese tetraoxide Manganese content% 71.5 Silica% 0.009 Potassium content% 0.002 Sodium content% 0.005 Calcium content% 0.002 M...

Embodiment 3

[0026] Embodiment three: the manganese carbonate (its water content is 5%) that gets 500kg is evenly mixed with the glucose (carbon source) of 40kg, then it is put into the continuous type microwave steel strip kiln and carries out microwave heating, controls its heating rate to be 10 ℃ / min, and the temperature is controlled at 650°C, and the sintering holding time is controlled for about 120 minutes, and then the manganese tetraoxide is obtained after cooling, and then the manganese tetraoxide is wet-milled to 1000 mesh, and the product manganese is obtained after testing The content is 71.2%, the unit energy consumption is 4600 degrees / ton, and the specific surface area is 7.8m 2 / g, and it is pure trimanganese tetraoxide by XRD analysis, and its specific indicators are shown in the table below.

[0027] Indicator name Trimanganese tetraoxide Manganese content% 71.2 Silica% 0.009 Potassium content% 0.002 Sodium content% 0.005 Calcium c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com