High-performance BiOCl/SnO2 heterojunction material and preparing method thereof

A heterojunction, high-performance technology, applied in chemical instruments and methods, chemical/physical processes, light water/sewage treatment, etc., can solve the problems of low photocatalytic efficiency and low energy conversion efficiency, and achieve a simple preparation method. The effect of easy operation, large specific surface area and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Dissolve 2.6221 g of tin tetrachloride and 0.98545 g of bismuth chloride in 125 ml of deionized water and stir until dissolved to obtain a mixed solution;

[0025] 2) Add 2.5g of PEG2000 into the above solution and stir for 1h;

[0026] 3) Place the mixed solution obtained in the above 2) in a water bath stirring device, stir at 50°C for 30 minutes, then add ammonia water with a mass fraction of 18% dropwise until the pH of the system is 8, and continue stirring for 24 hours to obtain a white precipitate thing;

[0027] 4) Suction filter the white precipitate obtained in 3), wash with distilled water and absolute ethanol three times respectively, dry the obtained product at 50°C, and then place it in a muffle furnace for calcination at 700°C for 3 hours to obtain BiOCl / SnO 2 Semiconductor nanoheterojunctions.

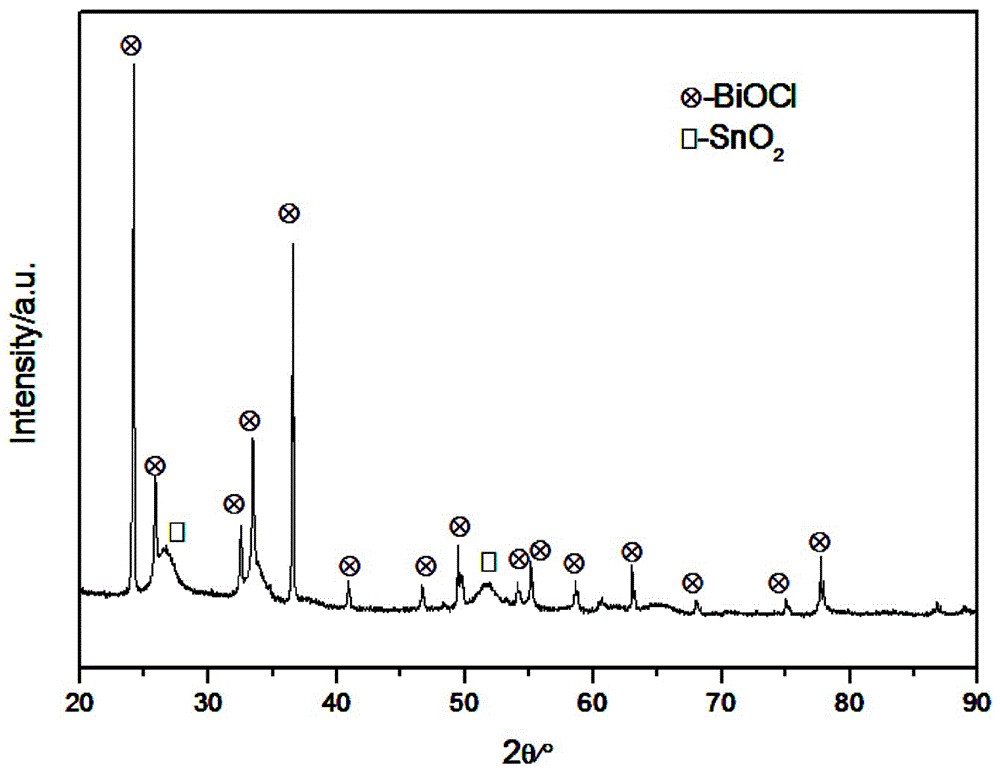

[0028] BiOCl / SnO prepared above 2 The X-ray diffraction pattern of semiconductor nanoheterojunction is as follows: figure 1 As shown, the diffraction peak...

Embodiment 2

[0031] 1) 1) 2.134g of tin tetrachloride and 1.5g of bismuth chloride were dissolved in 125ml of deionized water and stirred until dissolved to obtain a mixed solution;

[0032] 2) Add 2.0 g of PEG2000 into the above solution and stir for 1 h;

[0033] 3) Place the mixed solution obtained in the above 2) in a water bath stirring device, stir at 80°C for 20 minutes, then add ammonia water with a mass fraction of 18% dropwise until the pH value of the system is 7, and continue stirring for 24 hours to obtain a white precipitate thing;

[0034] 4) Suction filter the white precipitate obtained in 3), wash with distilled water and absolute ethanol three times respectively, dry the obtained product at 50°C, and then place it in a muffle furnace for calcination at 750°C for 3 hours to obtain BiOCl / SnO 2 Semiconductor nanoheterojunctions.

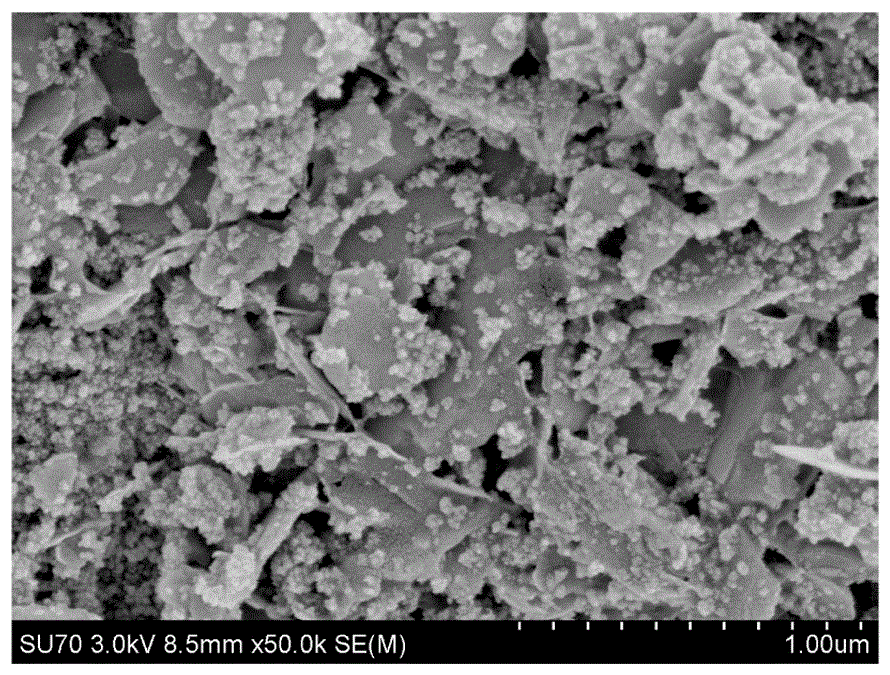

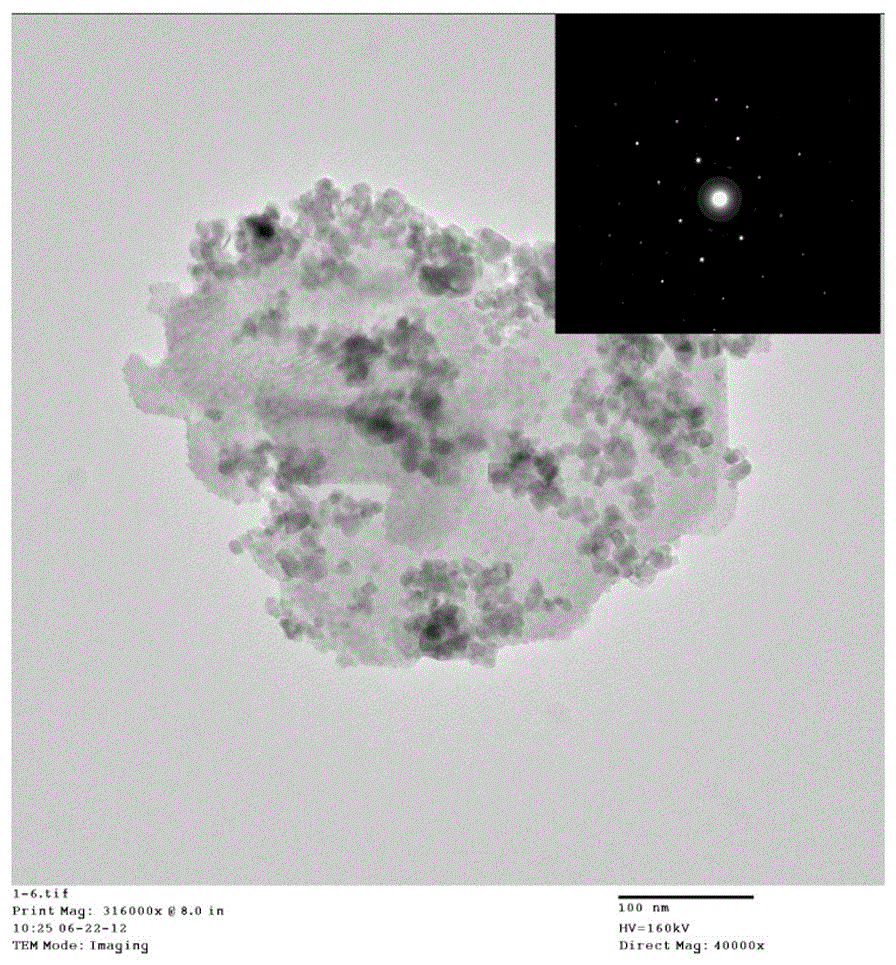

[0035] BiOCl / SnO prepared above 2 The transmission electron microscope spectrum of the semiconductor nano-heterojunction is as follows: image...

Embodiment 3

[0038] 1) 1.524g of tin tetrachloride and 2.156g of bismuth chloride were dissolved in 250ml of deionized water and stirred until dissolved to obtain a mixed solution;

[0039] 2) Add 2.5g of PEG1500 into the above solution and stir for 1h;

[0040]3) Place the mixed solution obtained in the above 2) in a water bath stirring device, stir at 60°C for 30 minutes, then add ammonia water with a mass fraction of 18% dropwise until the pH of the system is 7, and continue stirring for 24 hours to obtain a white precipitate thing;

[0041] 4) Suction filter the white precipitate obtained in 3), wash three times with distilled water and absolute ethanol respectively, dry the obtained product at 70°C, and then place it in a muffle furnace for calcination at 700°C for 4h to obtain BiOCl / SnO 2 Semiconductor nanoheterojunctions.

[0042] BiOCl / SnO prepared above 2 Photocatalytic performance test of semiconductor nano-heterojunction: 0.8g of BiOCl / SnO 2 The semiconductor nano-heterojunc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com