Anion/cation-doped and modified lithium ion battery (4:4:2)type ternary cathode material and preparation method thereof

A lithium-ion battery and compound doping technology, applied in battery electrodes, electrical components, secondary batteries, etc., can solve the problems of insufficient cycle performance and rate performance of ternary materials, and achieve improved cycle performance, cost reduction, and particle size distribution. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

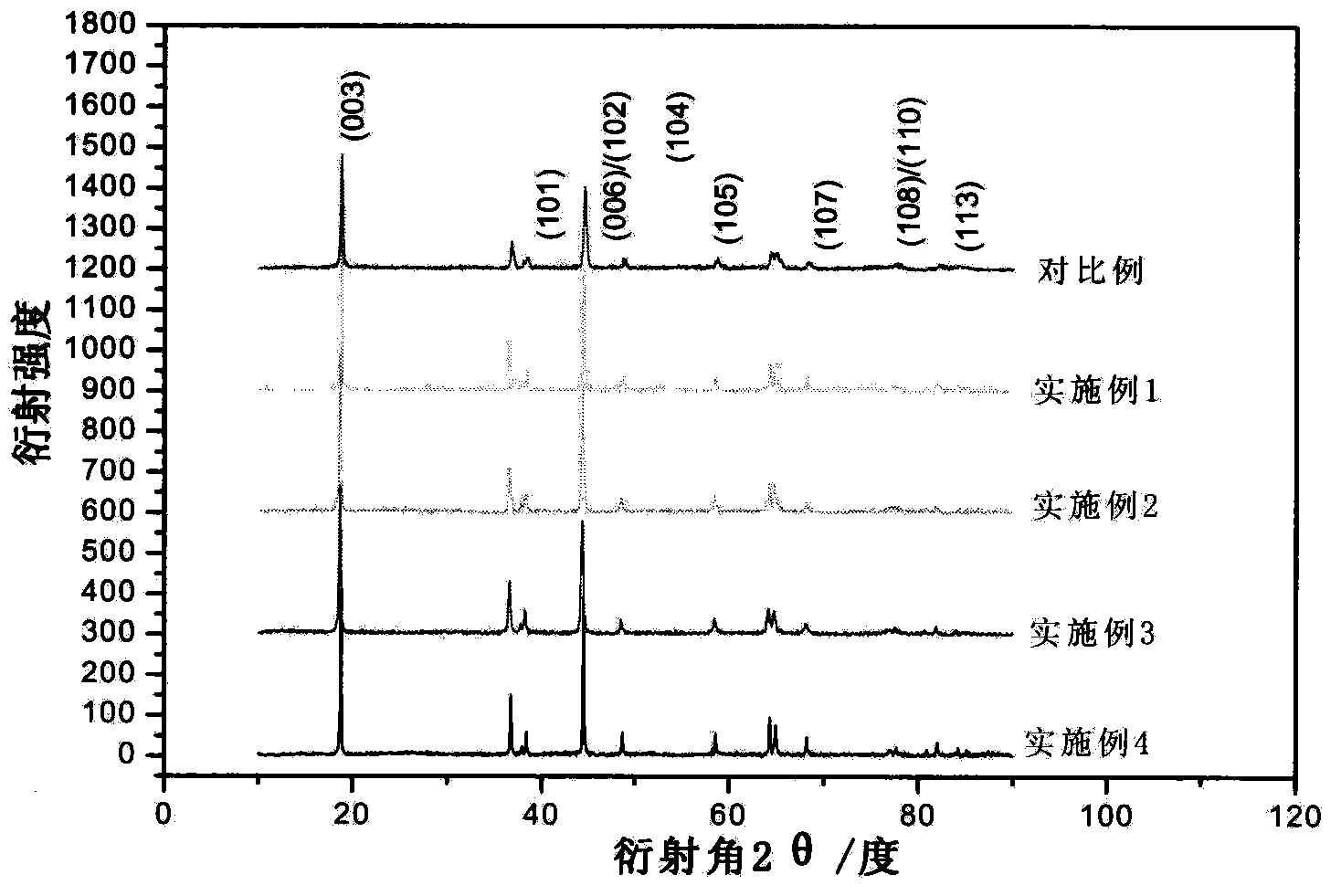

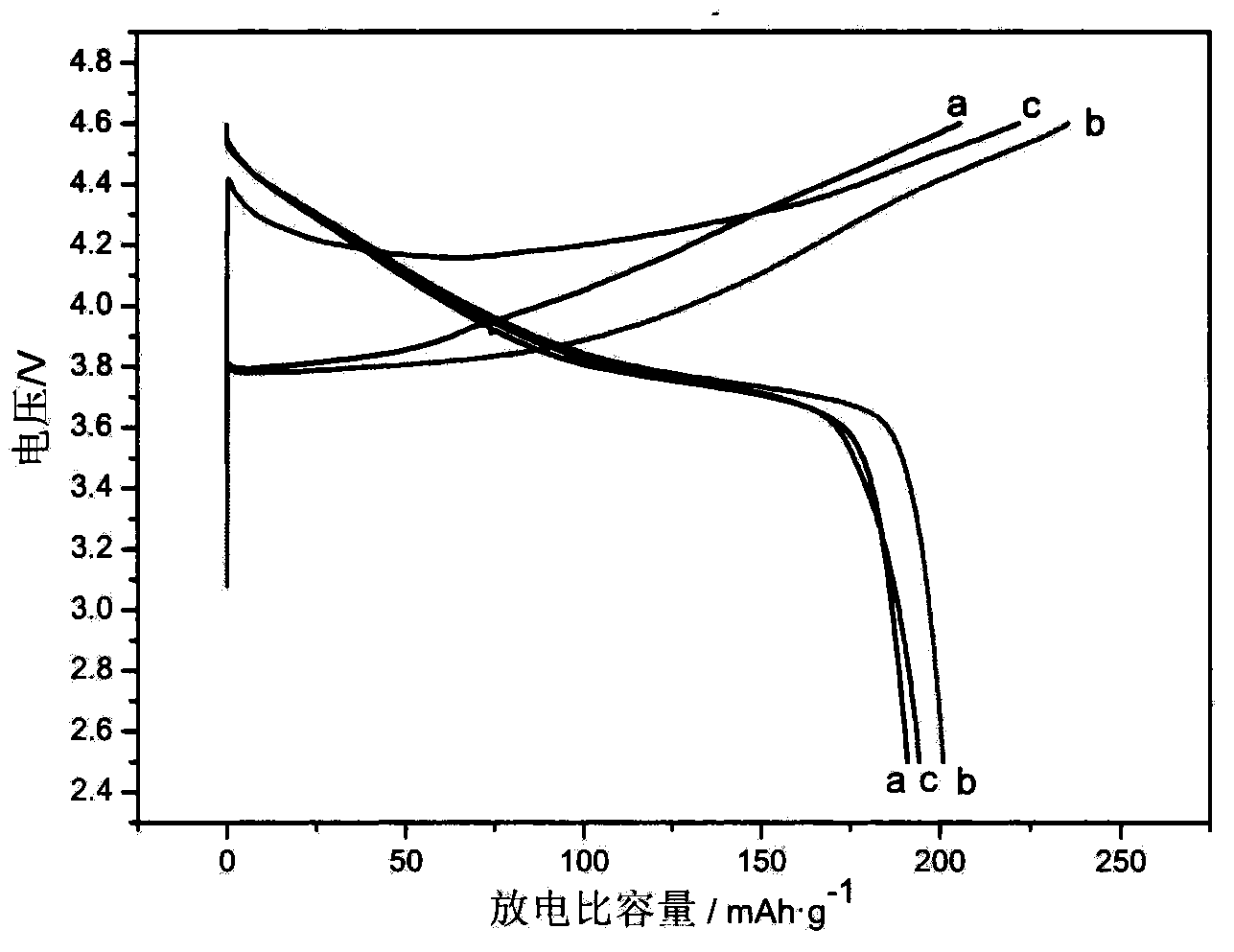

Embodiment 1

[0029] (1) Weigh analytically pure CH according to the stoichiometric ratio (1.02:0.388:0.194:0.388:0.03:0.03) 3 COOLi·2H 2 O, Ni(CH 3 COO) 2 4H 2 O, Co(CH 3 COO) 2 4H 2 O, Mn(CH 3 COO)·4H 2 O, Mg(NO 3 ) 2 ·6H 2 O and LiCl were dissolved completely with deionized water respectively, and citric acid solution was added in an amount equal to the sum of the molar amounts of transition metal ions. After mixing evenly, adjust the pH value to about 7 with concentrated ammonia water;

[0030] (2) heating the mixed solution obtained in step (1) in a water bath at 60° C. to evaporate water, and stirring continuously to obtain a gel;

[0031](3) drying the gel body in a blast drying oven, the drying temperature is 80°C, and the drying time is 8 hours to obtain a dry gel body;

[0032] (4) Pre-calcining the dried gel, the pre-calcination temperature is 300°C, and the pre-calcination time is 4 hours to obtain the precursor; the precursor is naturally cooled to room temperature ...

Embodiment 2

[0034] (1) Weigh analytically pure LiNO according to the stoichiometric ratio (0.95:0.36:0.18:0.36:0.1:0.1) 3 , Ni(NO 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O, Mn(NO 3 ) 2 4H 2 O, Mg(NO 3 ) 2 ·6H 2 O and LiCl were dissolved completely with deionized water respectively, and citric acid solution was added in an amount equal to the sum of the molar amounts of transition metal ions. After mixing evenly, adjust the pH value to about 7.5 with concentrated ammonia water;

[0035] (2) heating the mixed solution obtained in step (1) in a water bath at 80° C. to evaporate water, and stirring continuously to obtain a gel;

[0036] (3) drying the gel body in a blast drying oven, the drying temperature is 100° C., and the drying time is 10 hours to obtain a dry gel body;

[0037] (4) Pre-calcining the dried gel, the pre-calcination temperature is 400°C, and the pre-calcination time is 5 hours to obtain the precursor; the precursor is naturally cooled to room temperature and ground, a...

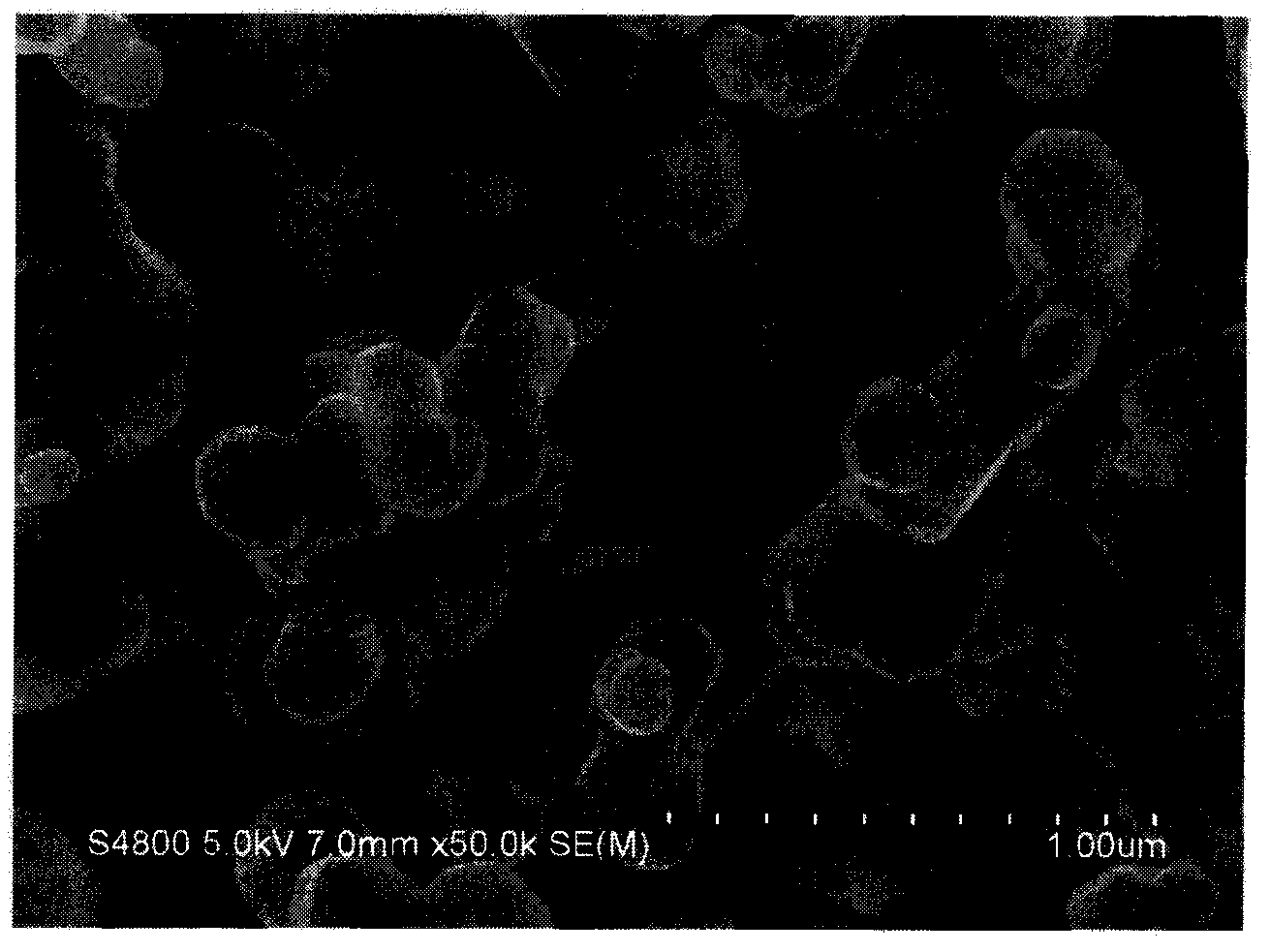

Embodiment 3

[0039] (1) Weigh analytically pure LiOH·H 2 O, Ni(CH 3 COO) 2 4H 2 O, Co(CH 3 COO) 2 4H 2 O, Mn(CH 3 COO)·4H 2 O, Mg(NO 3 ) 2 ·6H 2 O and LiCl were dissolved completely with deionized water respectively, then added citric acid solution in an amount equal to the sum of the molar amounts of transition metal ions, mixed evenly, and adjusted the pH value to about 8 with concentrated ammonia water;

[0040] (2) heating the mixed solution obtained in step (1) in a water bath at 90° C. to evaporate water, and stirring continuously to obtain a gel;

[0041] (3) drying the gel body in a blast drying oven, the drying temperature is 120° C., and the drying time is 12 hours to obtain a dry gel body;

[0042] (4) Pre-calcining the dried gel, the pre-calcination temperature is 500°C, and the pre-calcination time is 6 hours to obtain the precursor; the precursor is naturally cooled to room temperature and ground, and the ground precursor is ground at 900°C Carry out calcination, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com