Mine milling method for improving particles size distribution of bauxite mine milling products

A particle size distribution, bauxite technology, applied in the direction of aluminum compounds, chemical instruments and methods, wet separation, etc., can solve the problems of excessive fine particles, uneven particle size distribution of bauxite grinding products, etc. Grinding, reducing sliming and overgrinding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

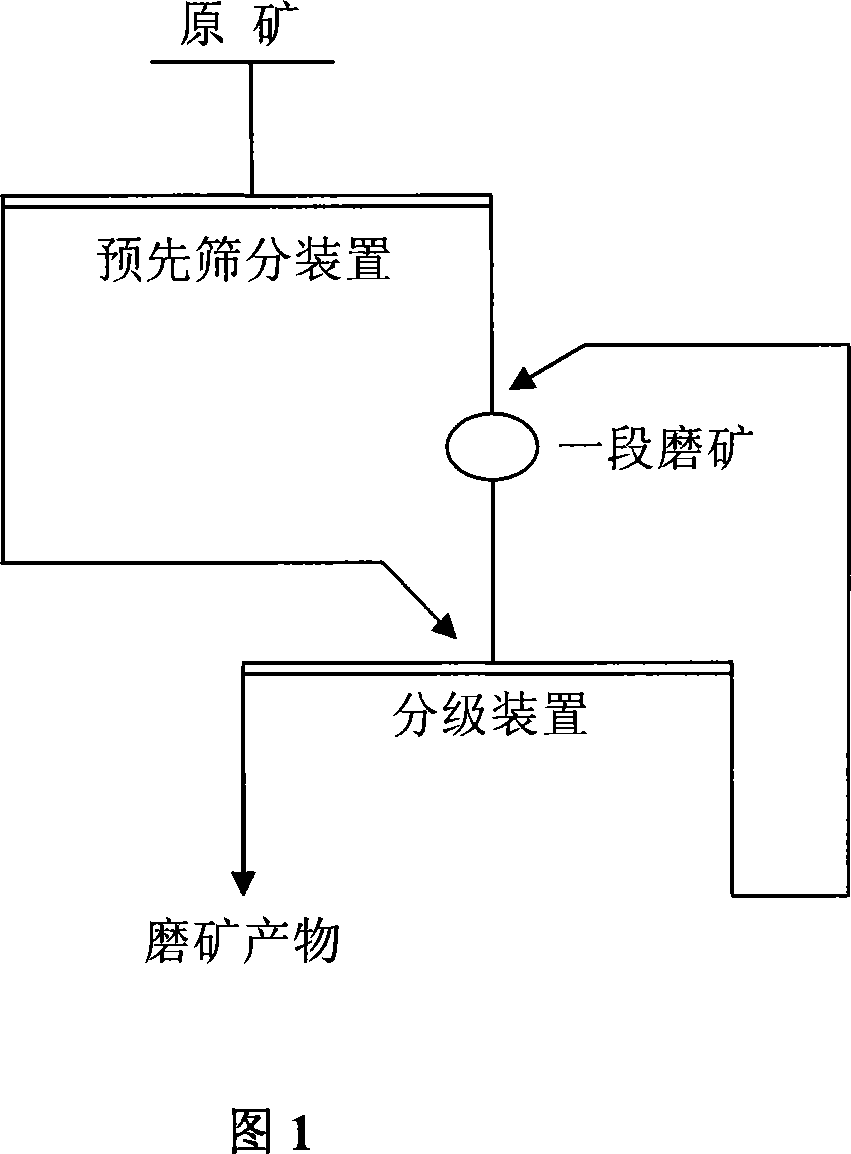

[0024] A comprehensive ore sample 1, raw ore Al in Henan bauxite mining area 2 O 3 56.79%, SiO 2 14.90%, the ratio of aluminum to silicon is 3.81. The principle process flow chart used is shown in Figure 1, and the raw ore particle size composition is shown in Table 1. The specific process is as follows:

[0025] The comprehensive ore sample 1 is dry sieved by a vibrating screen with an aperture of 15mm. The +15mm particle size product enters a short mill with an aspect ratio of 0.8, and the mill discharge product and -15mm particle size product use a spiral classifier For classification, the returned sand is returned to the mill for regrind under the action of spraying water at the top of the spiral classifier. The overflow of the classifier is used as the final product of grinding. The overflow concentration is 45-55%, and the overflow fineness is -0.074mm. 75-85%. In the particle size composition of the grinding product: +0.147mm accounts for 0~5%, -0.147+0.074mm accounts for 2...

Embodiment 2

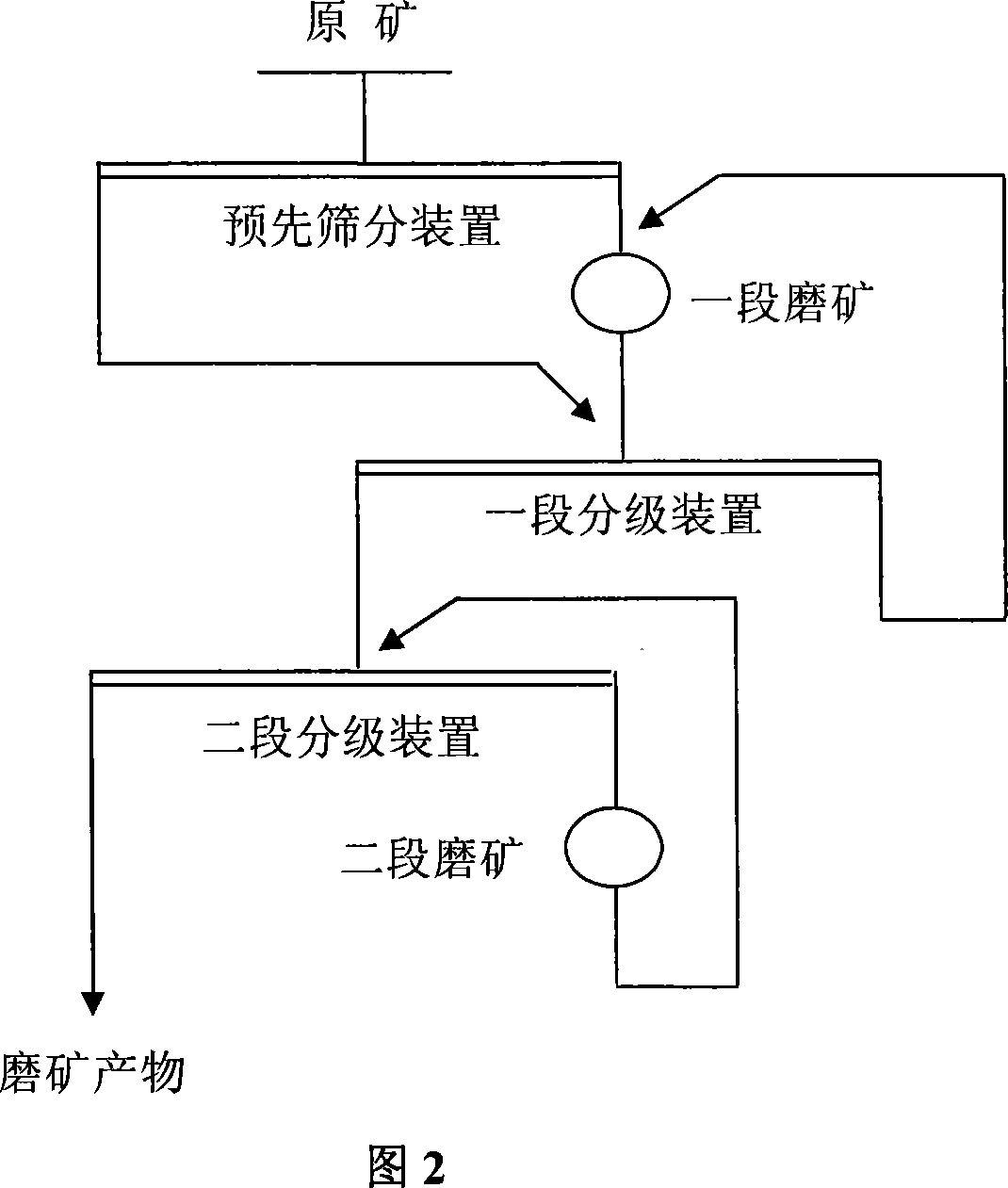

[0029] A comprehensive ore sample in Henan bauxite mining area 2, Al 2 O 3 53.71%, SiO 2 18.44%, the ratio of aluminum to silicon is 2.91. The principle process flow chart used is shown in Figure 2, and the raw ore particle size composition is shown in Table 3. The specific process is as follows:

[0030]The comprehensive ore sample 2 is dry sieved by a vibrating screen with an aperture of 10mm. The +10mm particle size product enters the short mill with a length-to-diameter ratio of 0.6. The mill discharge product and the -10mm particle size product use hydrocyclone. The grading underflow is returned to the first stage of grinding through a closed circuit, and the grading overflow is carried out for the second stage of classification. The concentration of the first stage is 40-55%, and the overflow fineness -0.074mm accounts for 65-75%. The second stage of grading underflow passes through the closed circuit. Return to the second stage grinding, the overflow of the second stage cla...

Embodiment 3

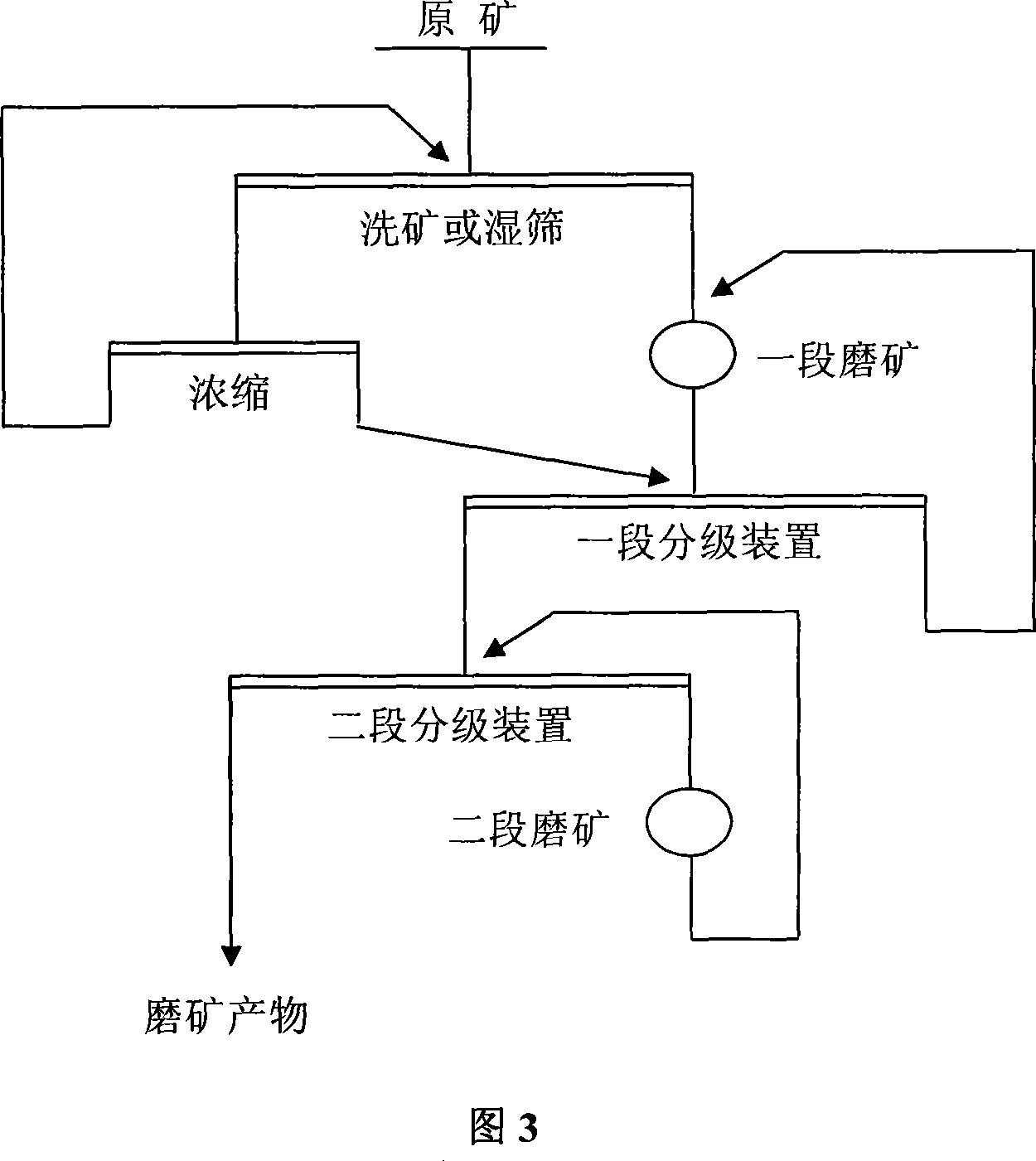

[0034] A comprehensive ore sample 3 in Henan bauxite mining area, Al 2 O 3 54.82%, SiO 2 17.62%, the ratio of aluminum to silicon is 3.11, the principle process flow chart used is shown in Figure 2, and the raw ore particle size composition is shown in Table 5. The specific process is as follows:

[0035] The comprehensive ore sample 2 is first washed with a cylindrical ore washing machine, and the obtained coarse or lump ore directly enters the mill. After the fine-grained product is concentrated, the overflow is returned to the ore washing operation through the pump. The underflow or sedimentation is mixed with the ore discharge product of the mill and classified together. The returned sand is returned to the first stage of grinding through a closed circuit, and the fine-grained product obtained by overflow is subjected to a second stage of classification. The overflow concentration of the first stage is 45-60%. The flow fineness -0.074mm accounts for 65 to 75%. The returned san...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com