Step branched ore milling and milling and dressing circular method

A grinding and branching technology, which is applied in chemical instruments and methods, solid separation, wet separation, etc., can solve problems such as uneven particle size of embedding, achieve mineral processing indicators and increase economic benefits, improve grinding environment, and tin recovery rate-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

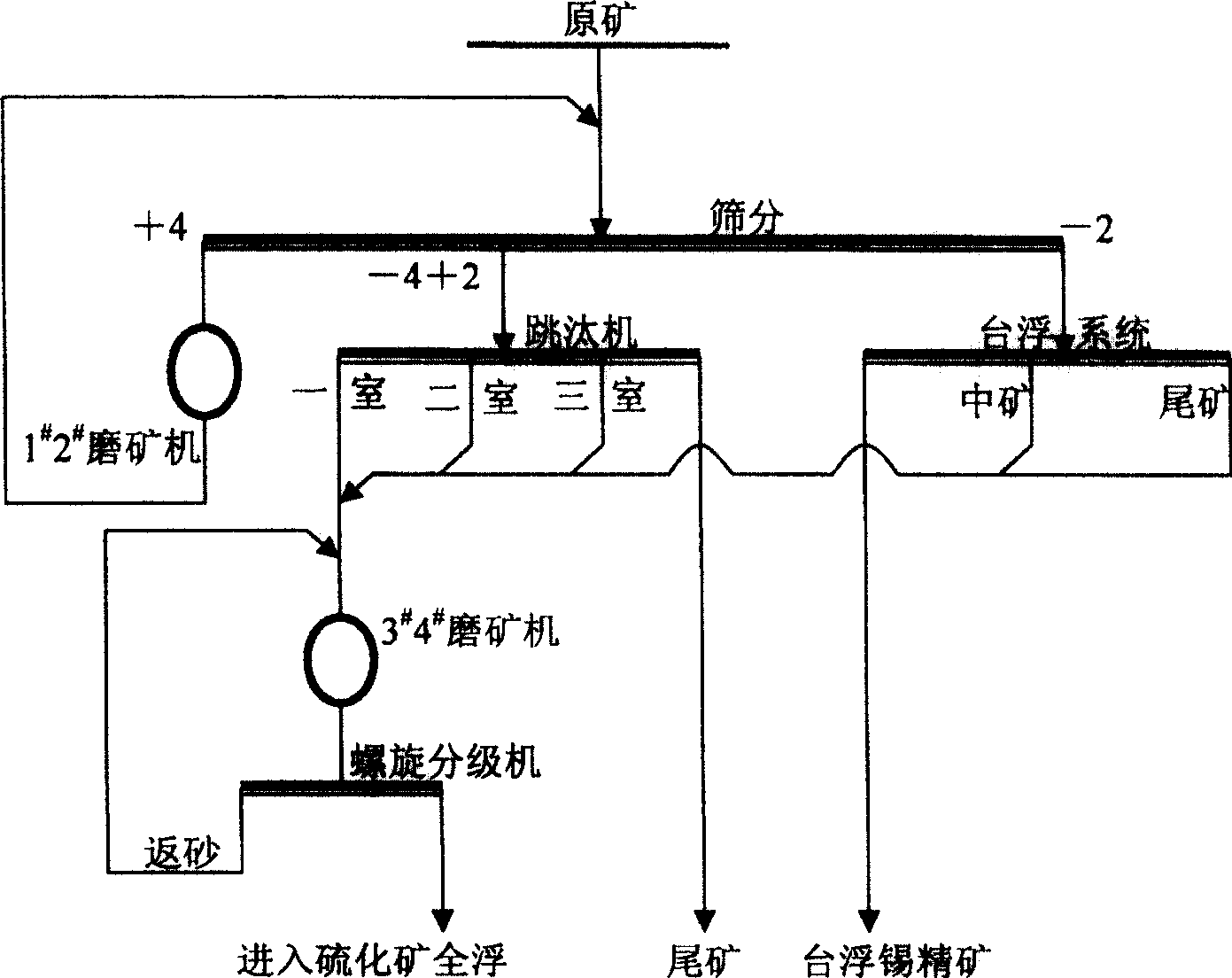

[0029] figure 1 The above background technology has been described, here is a brief description:

[0030] After the raw ore enters the screening system, it is screened immediately to separate the products on the upper sieve. The second-stage mill processes the jigging first, second, and third-room concentrates and the tailings in the floating bed. The spiral classifier and the second-stage mill are closed. Its overflow enters the full flotation of sulfide ore.

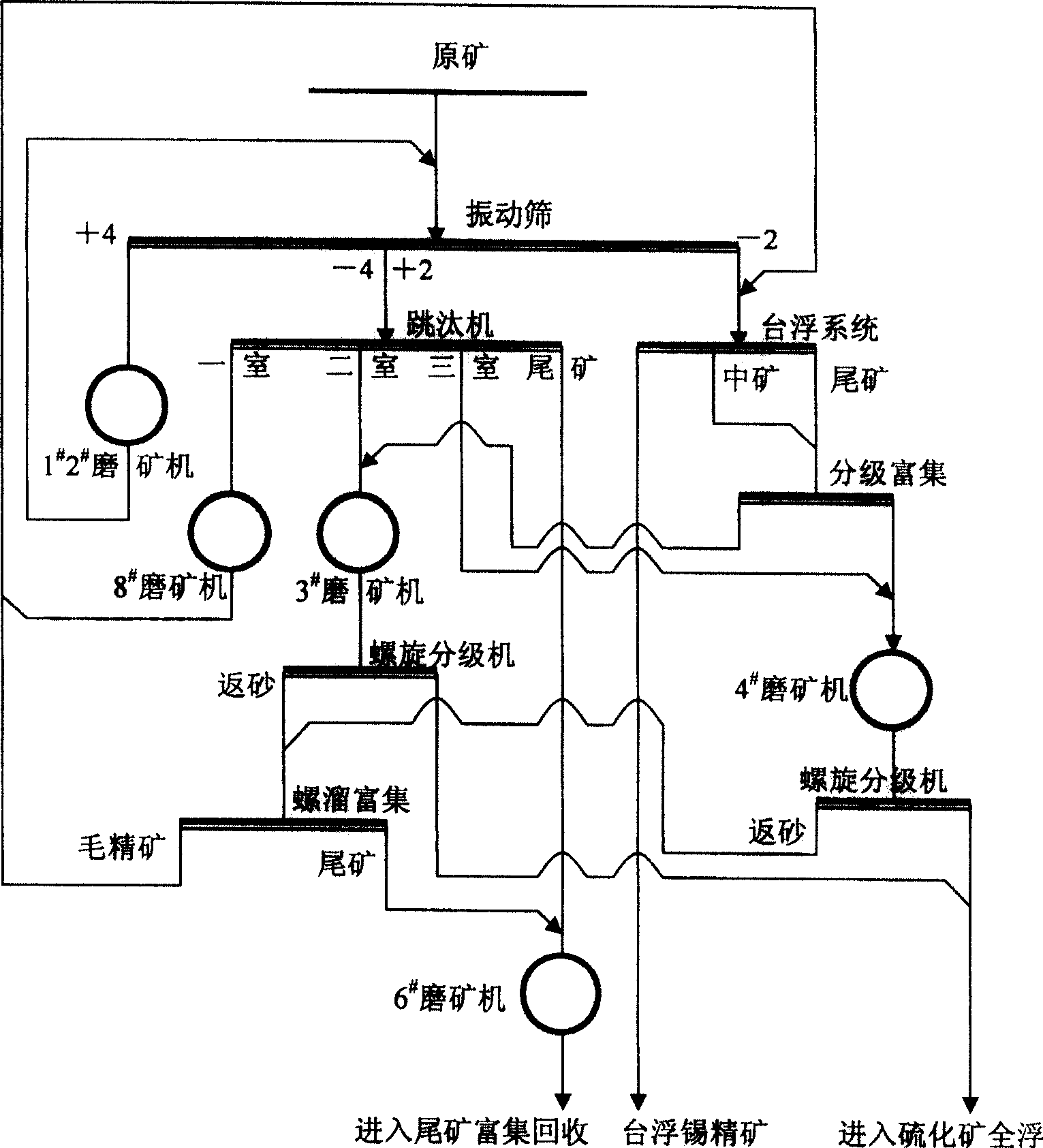

[0031] figure 2 Shown is the invention for figure 1 Improvement of the grinding production process:

[0032] The raw ore is screened into three products. The material larger than 4mm enters the raw ore and grinds to a particle size of less than 3mm, accounting for 70%. Then enter the stage floating system for sorting. The raw ore mill here starts the first sub-step, and the jigging first room, second room, third room and tailings enter the 8# mill, 3# mill, and 4# mill for the second step. Three-branch grinding, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com