Gravity classification and immersive screen combined classifying method and device utilizing same

A gravity classification and immersion technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of low screening efficiency, multi-power consumption, screen wear and other problems of fine particle screening equipment, and achieve improved Processing capacity per unit area and grading efficiency, enhanced grading effect, and effect of increasing the probability of settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

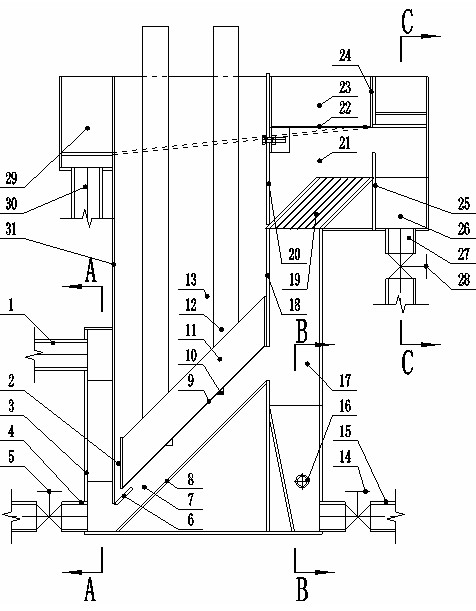

[0031] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0032] Gravity-hydraulic classification and submerged screen composite classification method of the present invention:

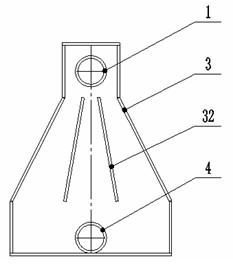

[0033] a. Feed the ore slurry from the feeding pipe 1 into the deflector distributor 3, and then enter the first screening and classifying chamber 7 to classify the material after being distributed by the deflector 32;

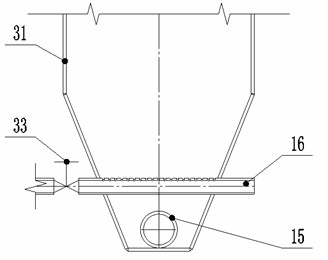

[0034] b. Adjust the parallel spacing and inclination angle between the first immersion screen 9 and the first screening chamber plate 8 through the adjustment rod 12 to adjust the grading particle size, and the fine particle material enters the first overflow through the first immersion screen 9 In the chamber 13, the coarse particle material moves upward along the first screening chamber plate 8 and enters the interference sedimentation classification chamber 17. During the classification process, the baffle plate 10 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com