Pulping system of papermaking production line

A production line and pulping technology, applied in papermaking, textile and papermaking, pulping of cellulose raw materials, etc., to achieve the effects of reducing transportation costs and production costs, reducing impurity backflow, and reducing slurry loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

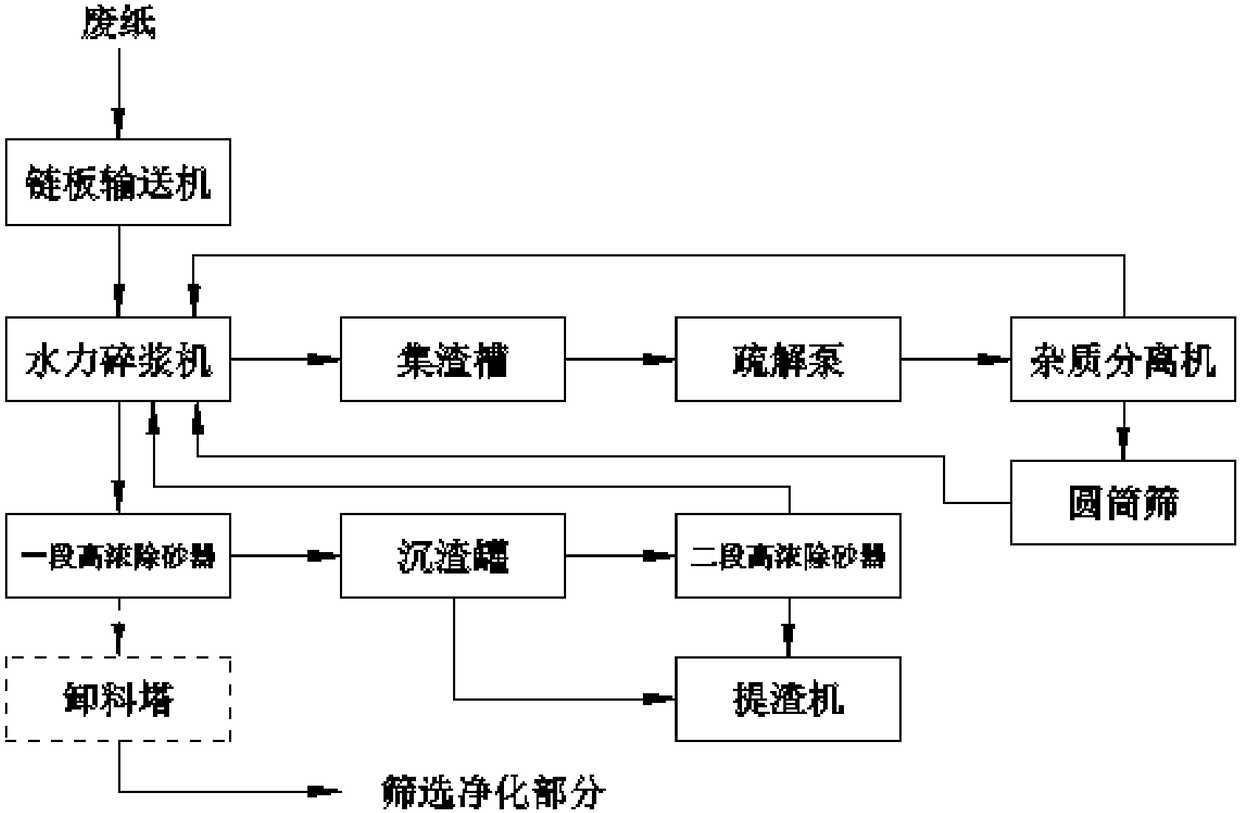

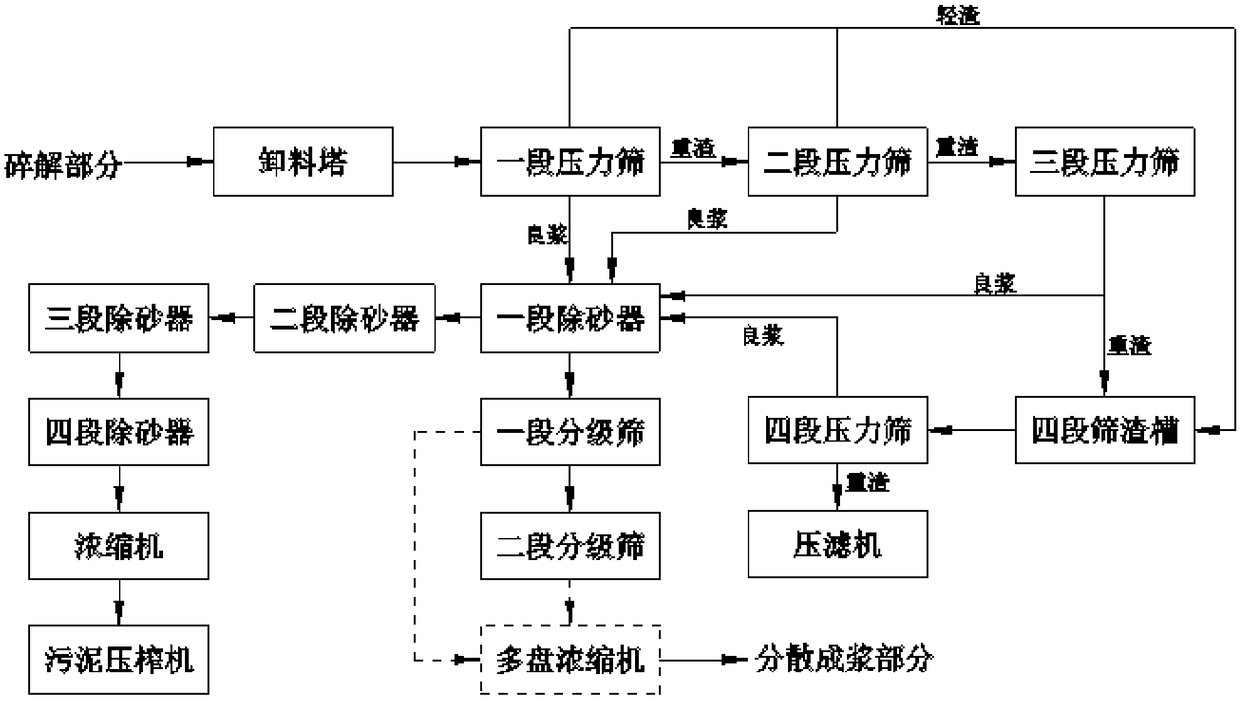

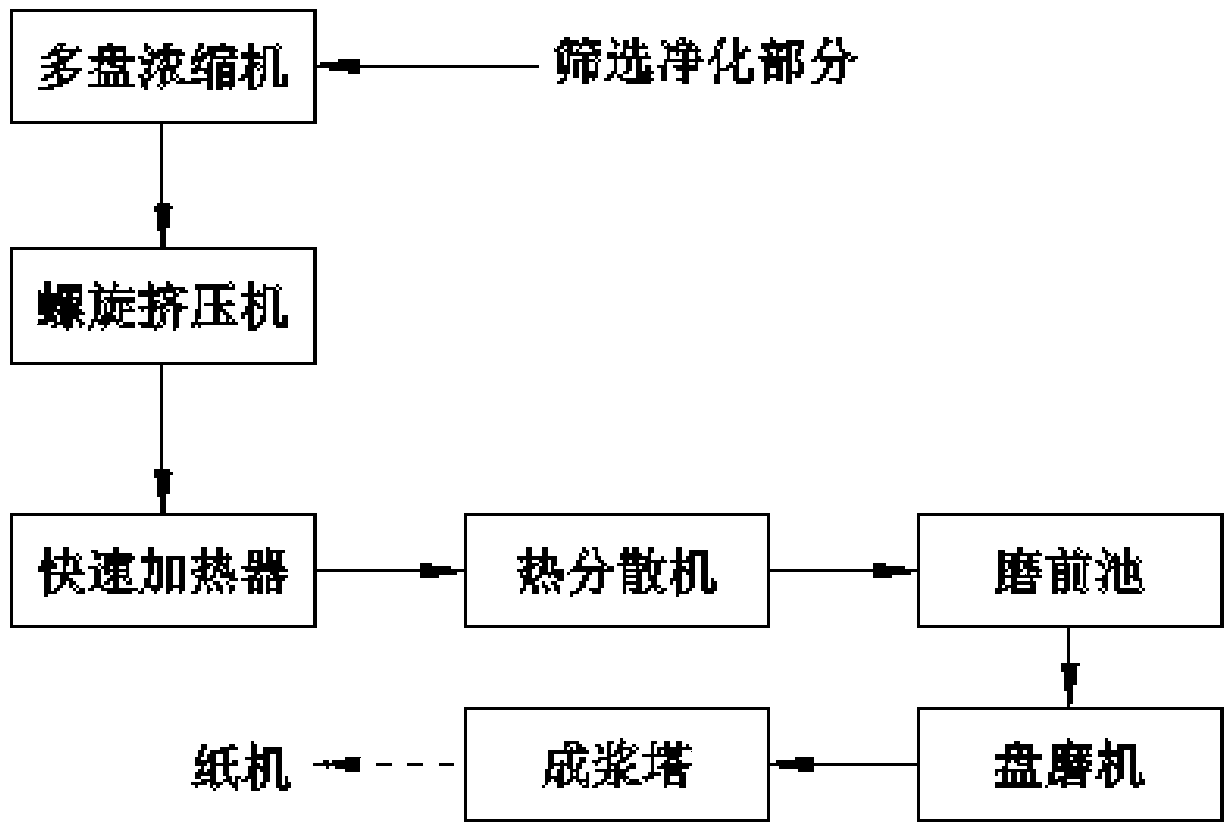

[0038] Such as figure 1 , figure 2 , image 3 As shown, this embodiment provides a papermaking production line pulping system, including a crushing part, a screening and purification part, and a pulping part; wherein, the crushing part includes a chain conveyor and a hydraulic pulper connected in sequence and a high-concentration desander; the screening and purification part includes a discharge tower, a pressure screen, a desander and a grading sieve connected in sequence, and a high-concentration desander in the crushing part is connected to the discharge tower; the dispersed The slurry part includes a multi-disk thickener, screw extruder, fast heater, heat disperser, pre-grinding tank, disc mill and slurry tower connected in sequence, and the grading screen in the screening and purification part is connected to the multi-disk thickener.

[0039] The system is divided into three parts to process and pulp the waste paper. The crushing part transports the waste paper to the...

Embodiment 2

[0045] This embodiment provides a papermaking production line pulping system, which is basically the same as Embodiment 1, except that in the screening and purification part, the structure of the screen drum body 1 of a pressure screen is as follows: Figure 4 As shown, the sieve drum body 1 is provided with a plurality of evenly spaced rectangular sieve slits 2 along the circumferential direction, and one or more spiral grooves 3 are set on the inner wall of the sieve drum body 1 from top to bottom along the circumferential direction, and the width of the sieve slits is 0.6mm; while the screen drum body 1 of the second-stage pressure screen, the third-stage pressure screen and the fourth-stage pressure screen all have circular screen holes, and the diameter of the screen hole on the screen drum body 1 of the second-stage pressure screen is 2.6mm The diameter of the sieve hole on the screen drum body 1 of the three-stage pressure screen is 2.5mm, and the diameter of the screen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com