Device and method for regulating potassium feldspar powder size distribution

A technology of particle size distribution and potassium feldspar powder, applied in grain processing and other directions, can solve the problems of wide range of particle size distribution, non-concentrated particle size, and inability to adjust potassium feldspar powder, so as to ensure dust-laden airflow concentration, facilitate pneumatic conveying, and facilitate air volume. The effect of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

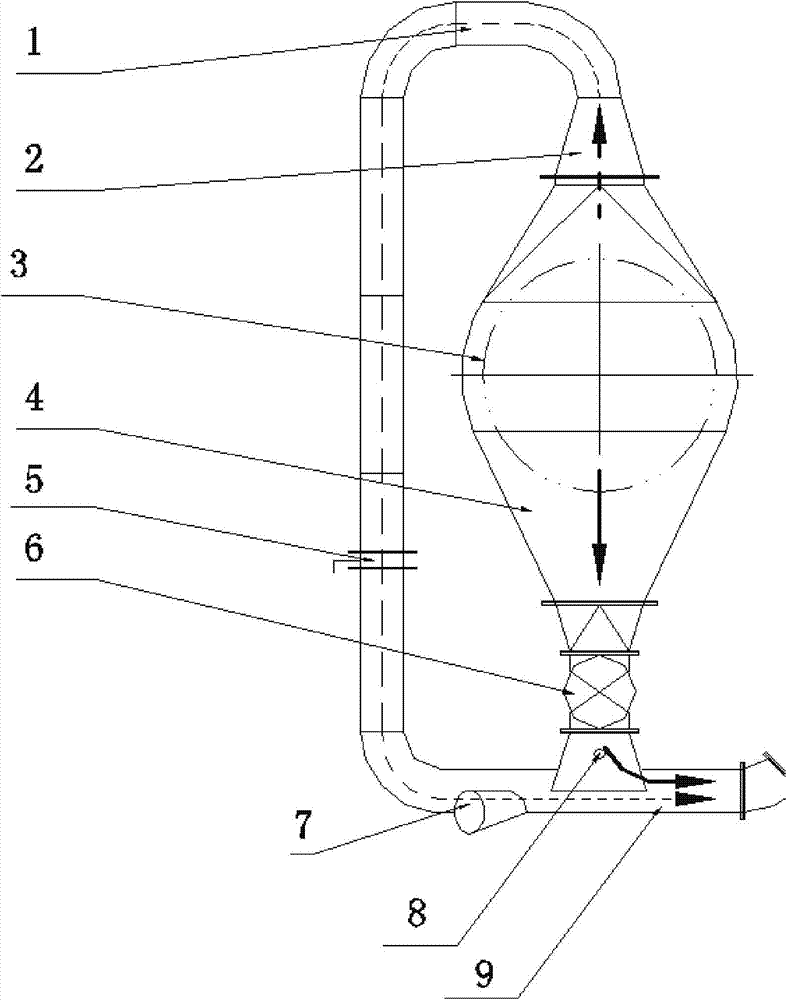

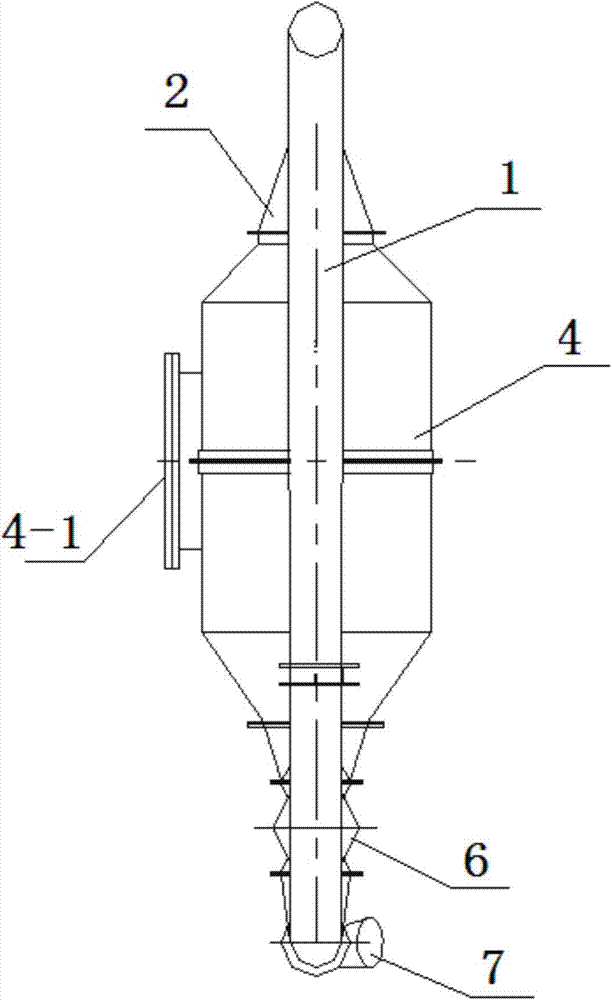

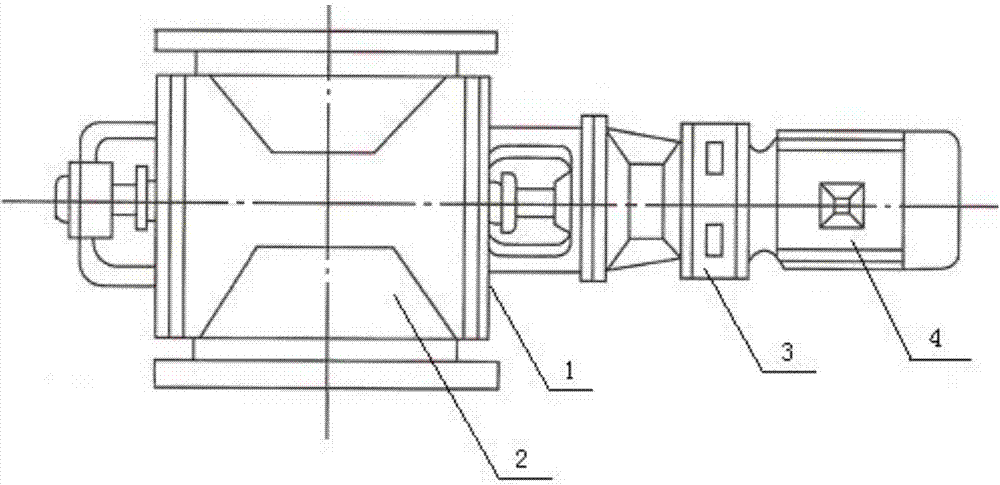

[0035] see Figure 1 to Figure 4 , the device for adjusting the particle size distribution of potassium feldspar powder in this embodiment includes an air volume adjustment system arranged on the discharge port of the ball mill, and the air volume adjustment system includes a feed bin 4, a main air pipe 1 and a side air inlet pipe 7; wherein, the The lateral middle part of the silo 4 is connected to the discharge port of the ball mill; one end of the main air duct 1 is connected to the upper end of the silo 4, and the other end extends downward and bends to form a tunnel passing below the silo 4. Convergence section 9, the lower end of the silo 4 is connected to the confluence section 9; the side air inlet pipe 7 is arranged on the confluence section 9, and an air volume adjustment switch is arranged in the side air inlet pipe 7 ; Between the lower end of the silo 4 and the confluence section 9, a rotary feeding valve 6 is provided.

[0036] see figure 1 and figure 2 , the...

Embodiment 2

[0040] This embodiment provides a method for adjusting the particle size distribution of potassium feldspar powder realized by using the device for adjusting the particle size distribution of potassium feldspar powder.

[0041] In this embodiment, it is required to produce ultrafine potassium feldspar powder, and its technical indicators are: 325 mesh sieve residue 5-8%, 200 mesh sieve residue less than 2%, fine powder below 10 μ less than 35%.

[0042] The adjustment method specifically includes the following steps:

[0043] (1) Adjust the regulating gate valve in the main air duct to the fully open maximum position, and adjust the air volume adjustment switch in the side air inlet duct to the fully open maximum position;

[0044] (2) Adjust the fan inlet valve of the system dust collector to keep the fan current in the range of 140A to 150A;

[0045] (3) Adjust the feeding amount of the ball mill through the electronic belt scale, and the feeding range is 3 to 5 tons per ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com