Grading method for olefin polymerization catalyst suspension liquid

A technology of olefin polymerization and classification method, which is applied in the field of olefin polymerization catalysts, and can solve problems such as large environmental impact, small particle size, and sieving method is not suitable for accurately controlling the particle size of catalyst components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

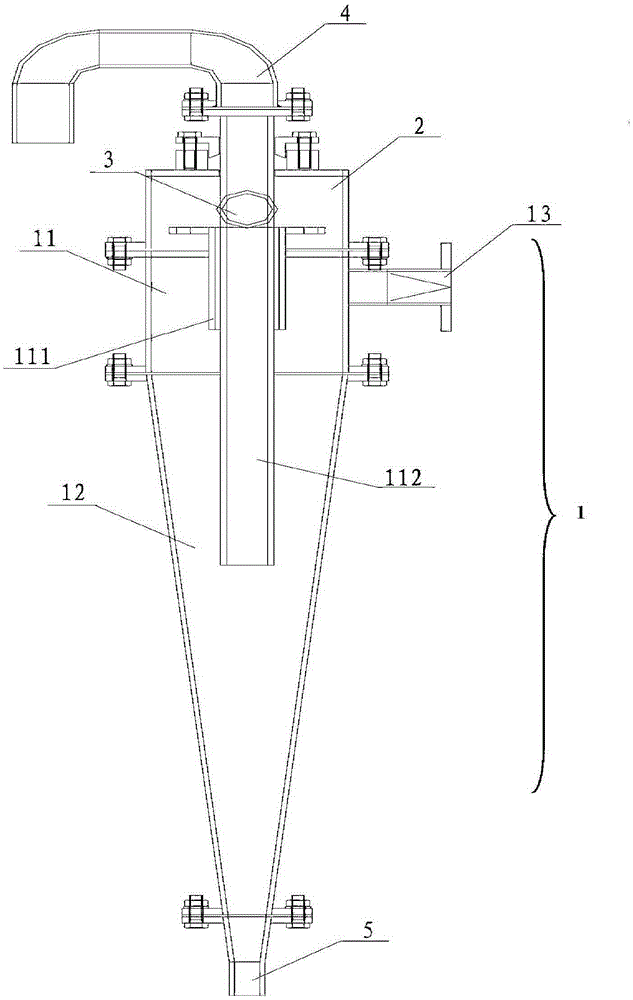

Image

Examples

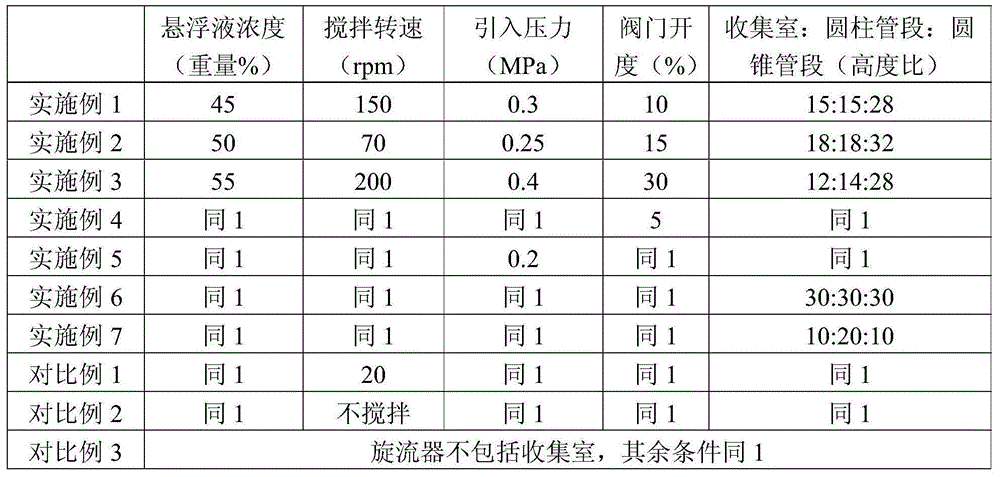

Embodiment 1-7 and comparative example 1-3

[0052] The olefin polymerization catalyst suspension was prepared according to the method in Example 1 of patent CN85100997, except that the catalyst components were washed with hexane and not vacuum-dried to obtain the olefin polymerization catalyst slurry suspension shown in Examples 1-10.

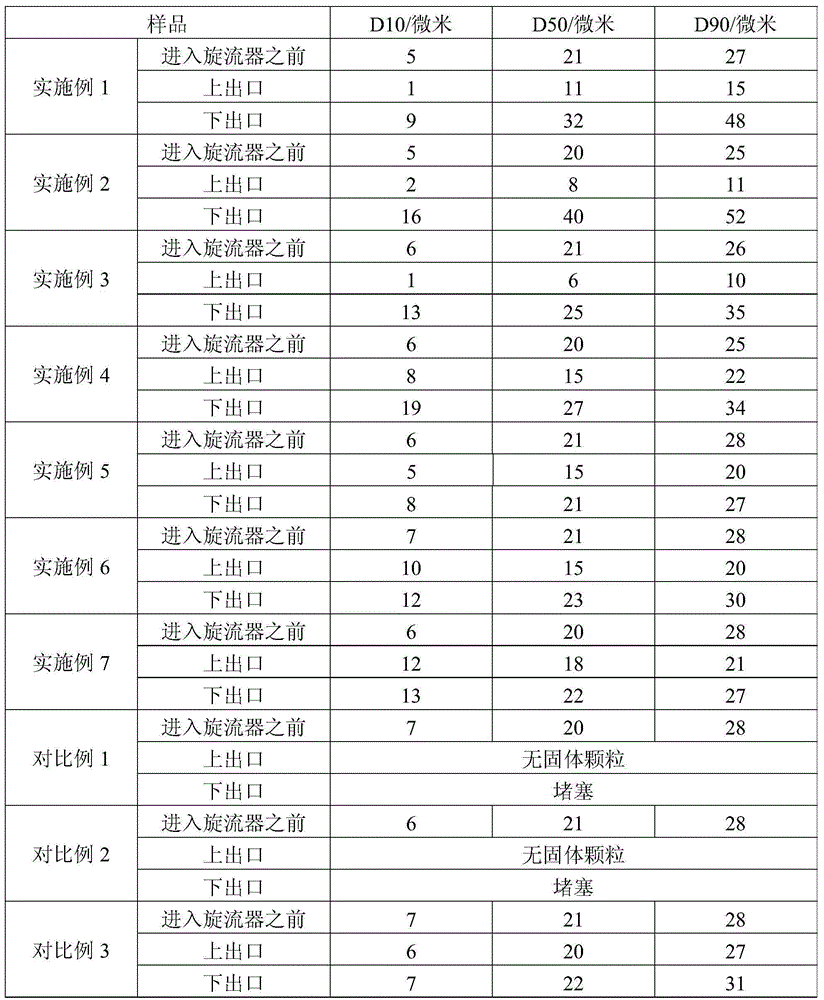

[0053] According to the conditions shown in Examples 1-7 and Comparative Examples 1-3, the reaction kettle pipeline is connected with the cyclone inlet pipeline, and the outlet (abbreviated as the upper outlet) of the cyclone on the collection chamber and the outlet on the cone are opened. The outlet at the lower part of the pipe section 12 (referred to as the lower outlet) allows the suspension to enter the cyclone under the conditions of nitrogen atmosphere pressure and stirring. The particle size of the suspension before entering the cyclone, the suspension obtained from the upper outlet and the lower outlet is determined. Wherein, the determination of particle size uses the British M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com