Preparation method of isoniazid slow release microspheres

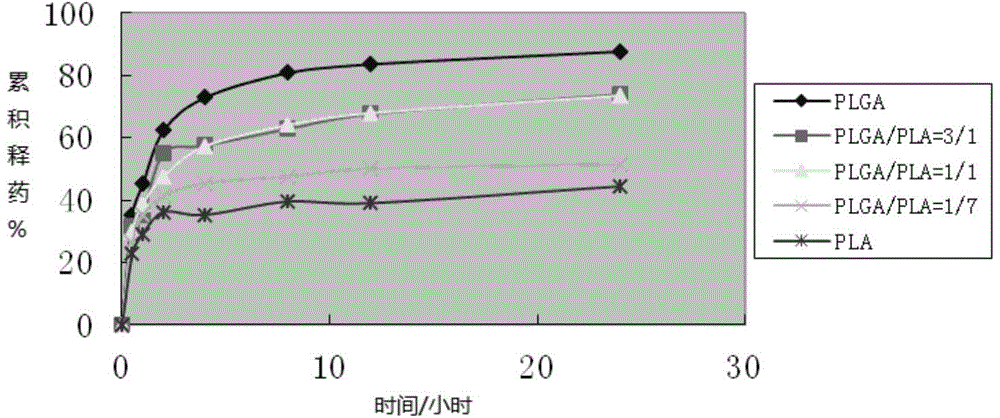

A technology of sustained-release microspheres and isoniazid, which is applied in the field of medicine, can solve the problem of not establishing a sustained-release system, and achieve the effects of reducing lung burden, small burst release and high encapsulation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] The preparation of embodiment 1 isoniazid micropowder particles

[0121] Take 0.5g of isoniazid bulk drug and place it in a ball mill, mix it with 20g of grinding balls, then add 3ml of dichloromethane, and grind for 2h with a rotating speed of 650rpm; 161±0.106nm).

Embodiment 2

[0122] The preparation of embodiment 2 isoniazid polylactic acid microspheres (IN-PLA-MS)

[0123] Get 40 mg of isoniazid micropowder particles prepared in Example 1, ultrasonically disperse in 40 ml of methylene chloride, add 800 mg of PLA [viscosity 0.49 dl / g (CHCl 3 / 25°C)], ultrasonically dissolved to obtain S / O suspension; the suspension was spray-dried (spray conditions: inlet temperature 60°C, nozzle cap aperture 5.5 μm), and isoniazid-polylactic acid microspheres were obtained.

[0124] According to the method of "1.2" of Experimental Example 1, the encapsulation efficiency of the isoniazid polylactic acid microspheres was 87.24%, and the drug loading was 4.99%.

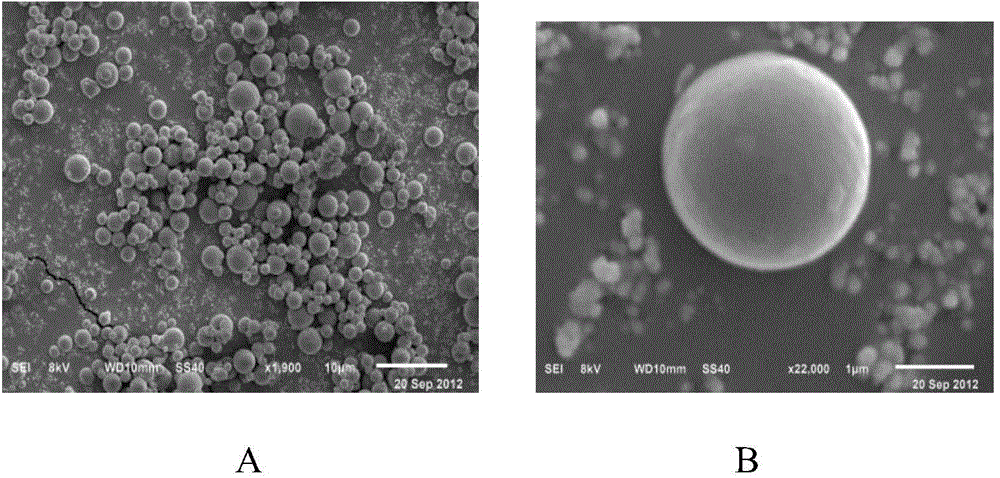

[0125] Scanning electron microscopy (SEM) was used to observe the morphology of the microspheres, and the results are shown in figure 2 . From figure 2 In A (overall picture), it can be seen that IN-PLA-MS has a round shape, smooth surface, good dispersion and no adhesion. From figure 2 In B (enlarged...

Embodiment 3

[0128] The preparation of embodiment 3 isoniazid-chitosan composition (IN-CTS)

[0129] Prepare a 1% acetic acid solution, weigh an appropriate amount of chitosan CTS (Mw50000-19000) and add it, stir and swell until completely dissolved, prepare a CTS solution with a concentration of 0.25% for use; press IN:CTS=1:1, take IN and add to In the prepared CTS solution, stir until IN is completely dissolved. While stirring, add TPP aqueous solution according to sodium tripolyphosphate TPP:CTS=3:5 for cross-linking. After low-speed stirring, use B90 spray dryer for spray drying (inlet temperature 90 ℃, outlet temperature ℃, pump speed 2.4mL·min-1) to obtain the isoniazid-chitosan composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com