Soil conditioner and method for its preparation and use

A soil conditioner and conditioner technology, which is applied in the field of soil remediation, can solve the problems of high quality and precision requirements, cumbersome and complicated calculations, etc. The effect of reducing the concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Soil conditioner, this conditioner comprises the following components by weight percentage:

[0071] Copper tailings 60%

[0072] Fluorite tailings 30%

[0073] Talc 6%

[0074] Carboxymethyl Cellulose 4%

[0075] Among them, the particle size of each component in the modifier is less than 0.5mm, accounting for more than 90%;

[0076] The preparation method of soil conditioner comprises the following steps:

[0077] Step 1. Weigh each component and mix well;

[0078] Step 2, the mixture obtained in step 1 is made into 5-10mm pellets;

[0079] Step 3, calcining the pellets at a temperature of 1300° C. for 2.5 hours;

[0080] Step 4, cooling and activating the pellets, and ball milling to 100 mesh to obtain a soil conditioner.

[0081] Wherein, when the particle size of more than 10% of the added tailings is larger than 0.5 mm, ball milling can be carried out in step 1 first, and ball milling is performed until more than 90% of the particle size of each component i...

Embodiment 2

[0083] Soil conditioner, this conditioner comprises the following components by weight percentage:

[0084] Copper tailings 50%

[0085] Fluorite tailings 27%

[0086] Talc 20%

[0087] Carboxymethyl Cellulose 3%

[0088] Among them, the particle size of each component in the modifier is less than 0.5mm, accounting for more than 90%;

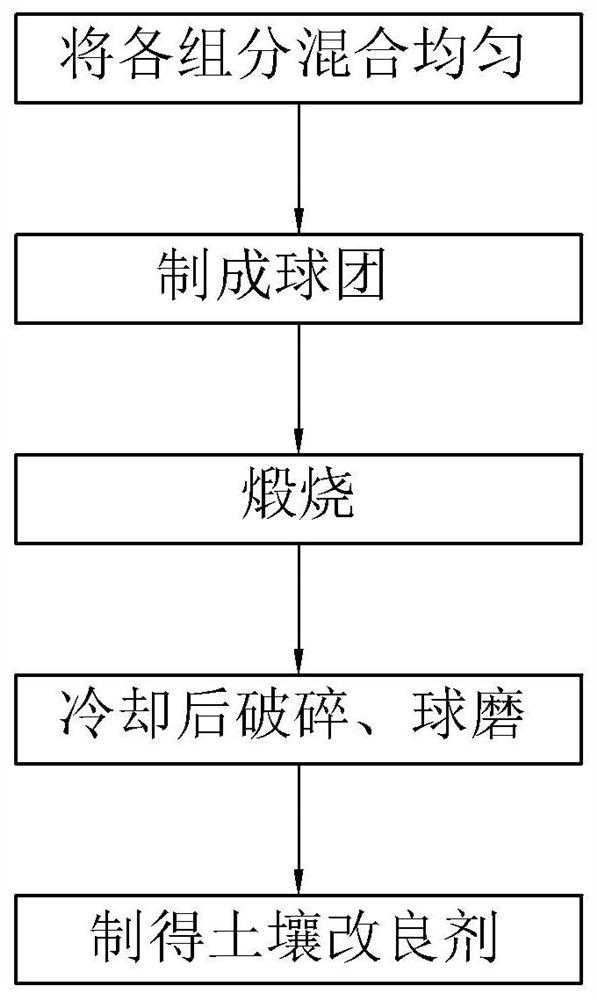

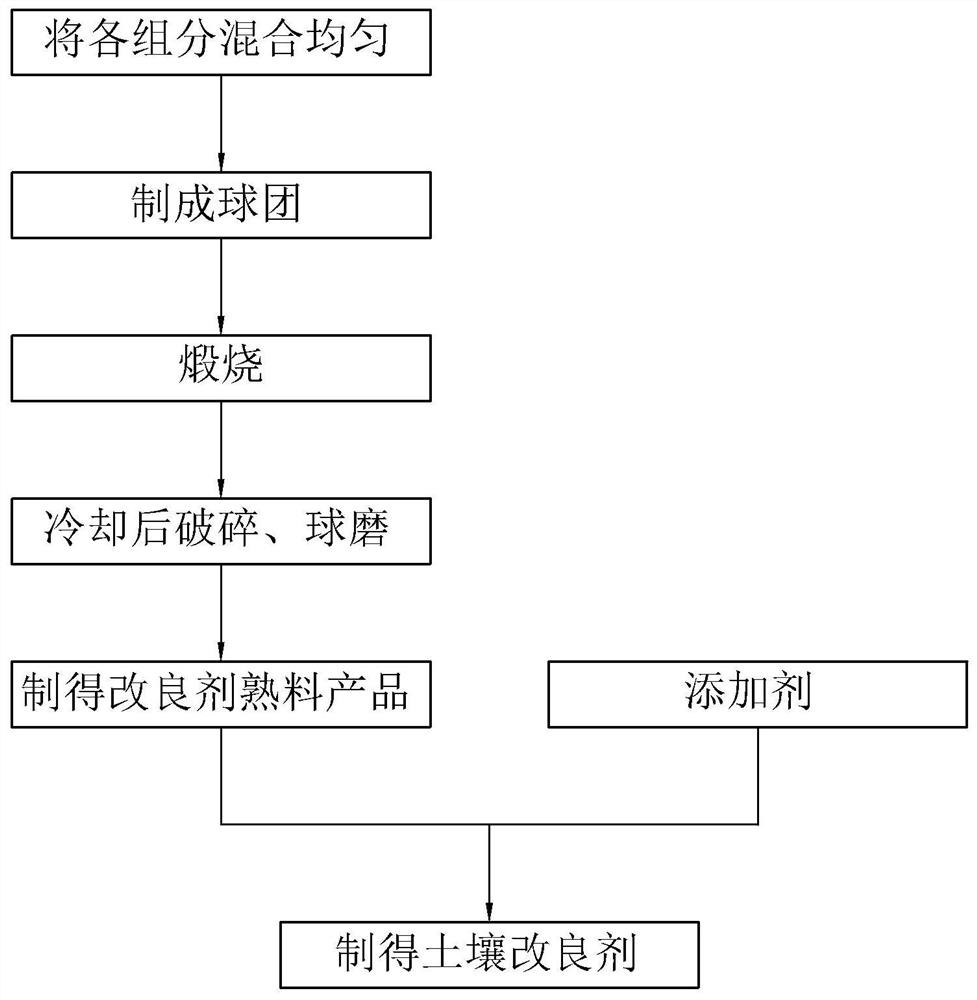

[0089] Soil conditioner preparation methods such as figure 1 shown, including the following steps:

[0090] Step 1. Weigh each component and mix well;

[0091] Step 2, the mixture obtained in step 1 is made into 50-100mm pellets;

[0092] Step 3, calcining the pellets at a temperature of 1150° C. for 2.0 hours;

[0093] Step 4, cooling and activating the pellets, and ball milling to 50 mesh to obtain a soil conditioner.

[0094] Wherein, when the particle size of more than 10% of the added tailings is larger than 0.5 mm, ball milling can be carried out in step 1 first, and ball milling is performed until more than 90% of the particle siz...

Embodiment 3

[0096] Soil conditioner, this conditioner comprises the following components by weight percentage:

[0097] Copper tailings 40%

[0098] Fluorite tailings 40%

[0099] Talc 15%

[0100] Carboxymethyl Cellulose 5%

[0101] Among them, the particle size of each component in the modifier is less than 0.5mm, accounting for more than 90%;

[0102] The preparation method of soil conditioner comprises the following steps:

[0103] Step 1. Weigh each component and mix well;

[0104] Step 2, the mixture obtained in step 1 is made into 5-10mm pellets;

[0105] Step 3, calcining the pellets at a temperature of 1000° C. for 1.5 hours;

[0106] Step 4, cooling and activating the pellets, and ball milling to 60 mesh to obtain a soil conditioner.

[0107] Wherein, when the particle size of more than 10% of the added tailings is larger than 0.5 mm, ball milling can be carried out in step 1 first, and ball milling is performed until more than 90% of the particle size of each component i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com