Patents

Literature

41results about How to "Increase the settlement area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

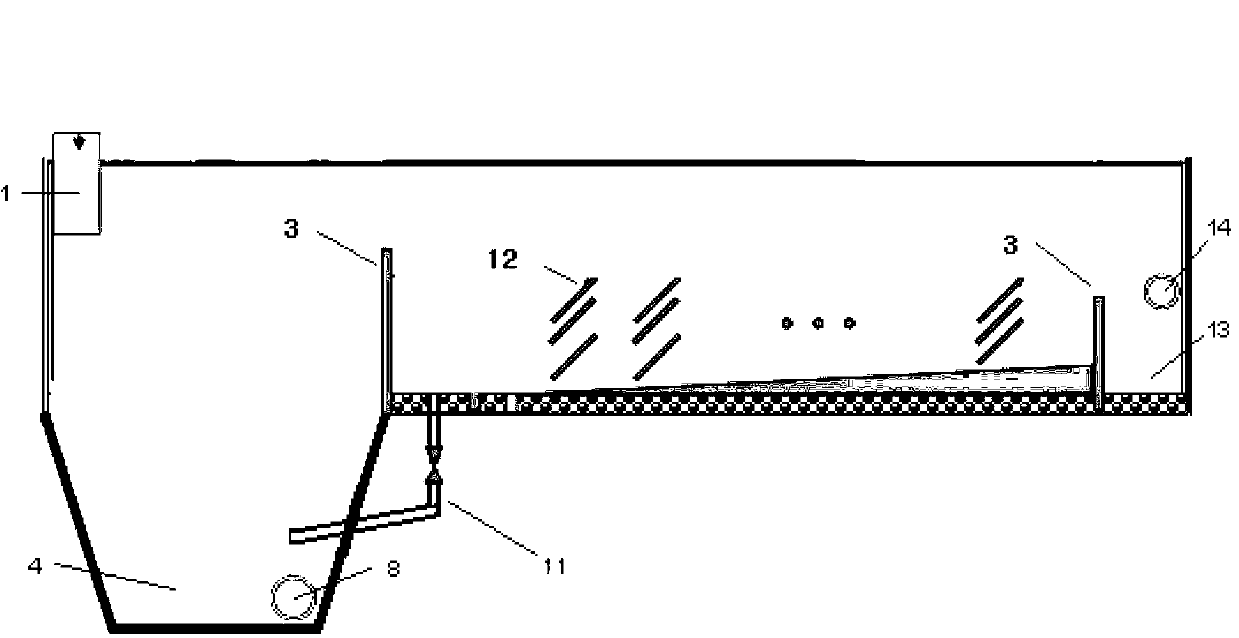

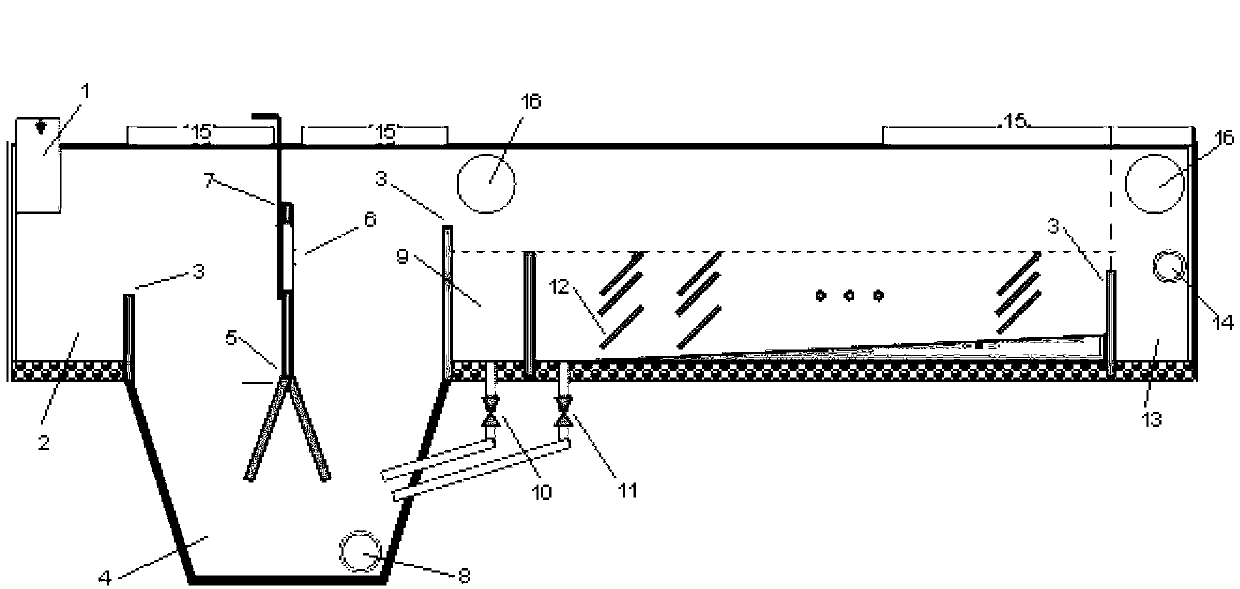

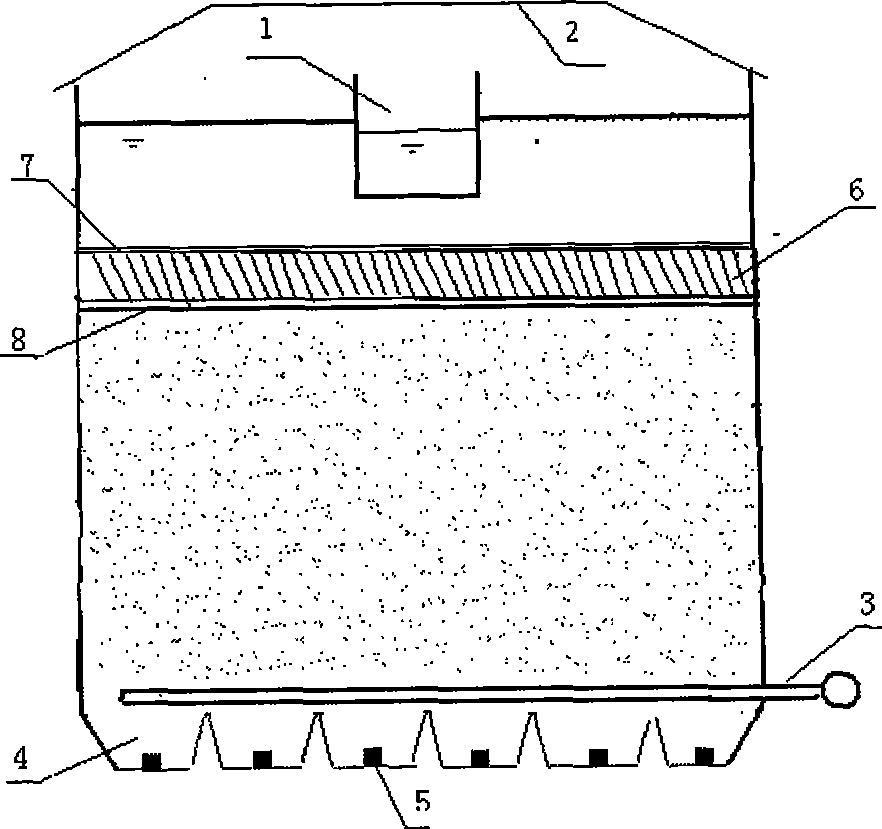

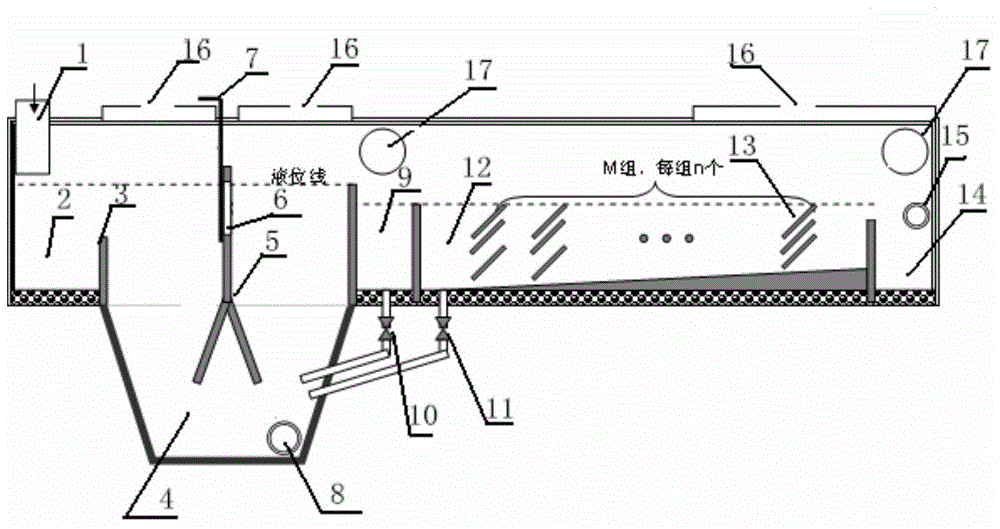

Canal type thickener

InactiveCN103100242AShorten the lengthSave materialSedimentation settling tanksHeavy particleMedicine

The invention relates to a canal type thickener, which is a canal overall. Along an ore pulp flow path, the thickener includes a canal head, a canal body and a canal tail in order. Ore pulp enters a thickening pond through a feeding port, heavy particles in the ore pulp undergo preliminary settlement in the thickening pond. The low concentration ore pulp overflowing the canal head enters the canal body to undergo further settlement. When the low concentration ore pulp flows to the canal tail, it is already in a clear water state basically and enters a clear water pond, and is discharged through a drain hole. In the invention, the thickener is changed from the traditional ''round pond'' type to the ''canal type'', thus effectively solving the problem of large floor area of the thickener. The canal structure is in linear arrangement, can be subjected to buried installation, and does not take up the volume of a concentrating mill basically. With a long canal and a large actual settlement area, the structure of the thickener can be simpler, thereby effectively reducing the production cost.

Owner:蔡宏武

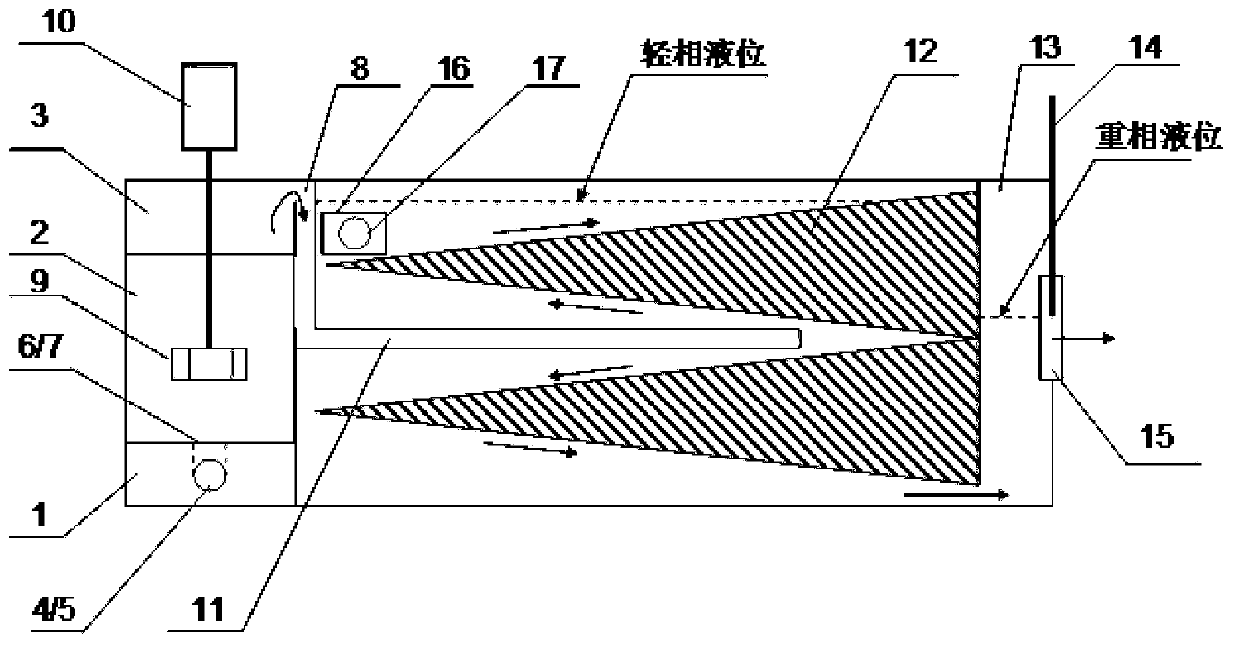

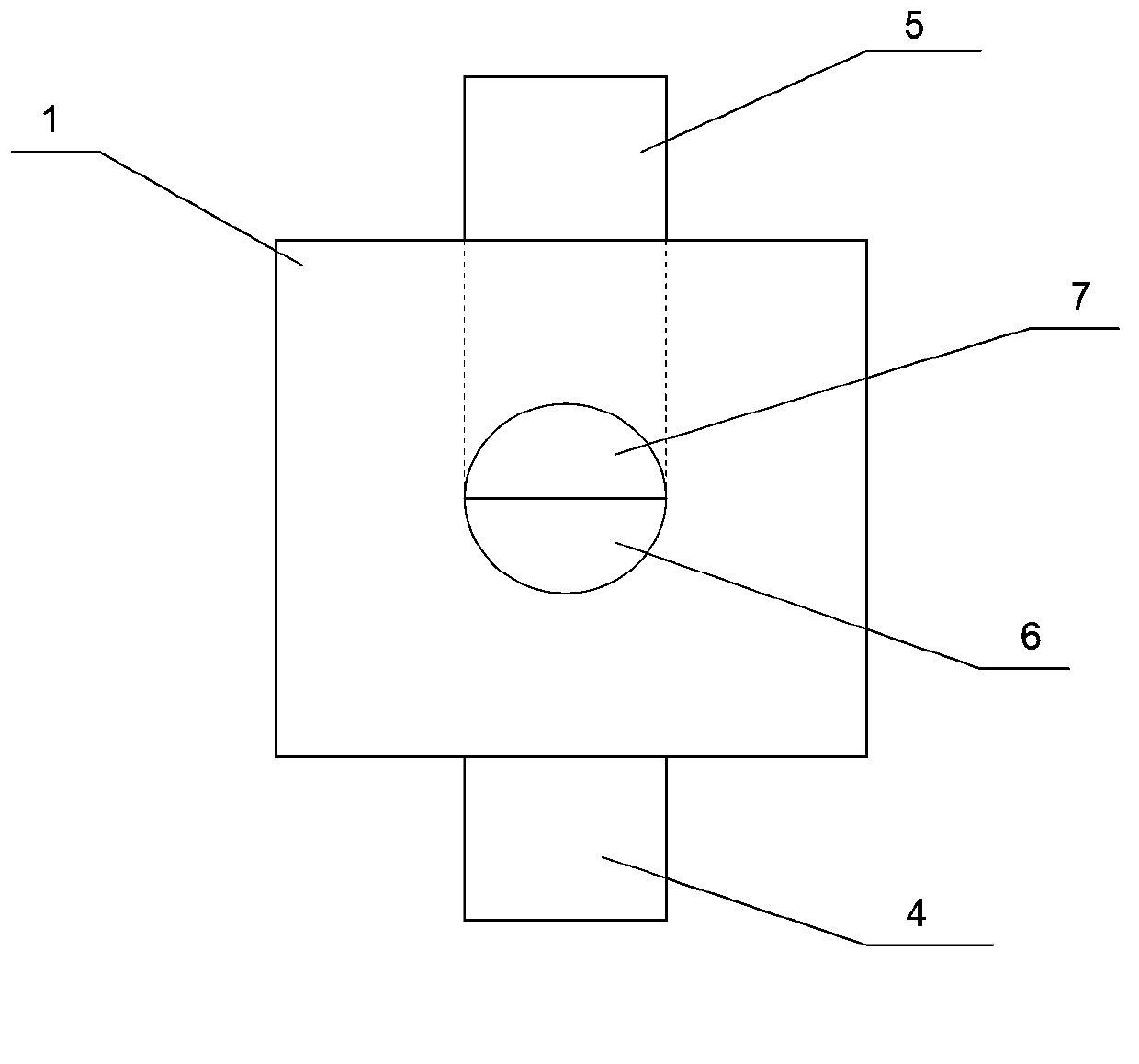

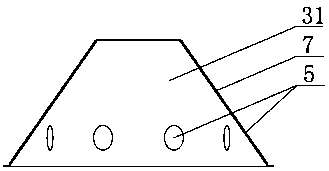

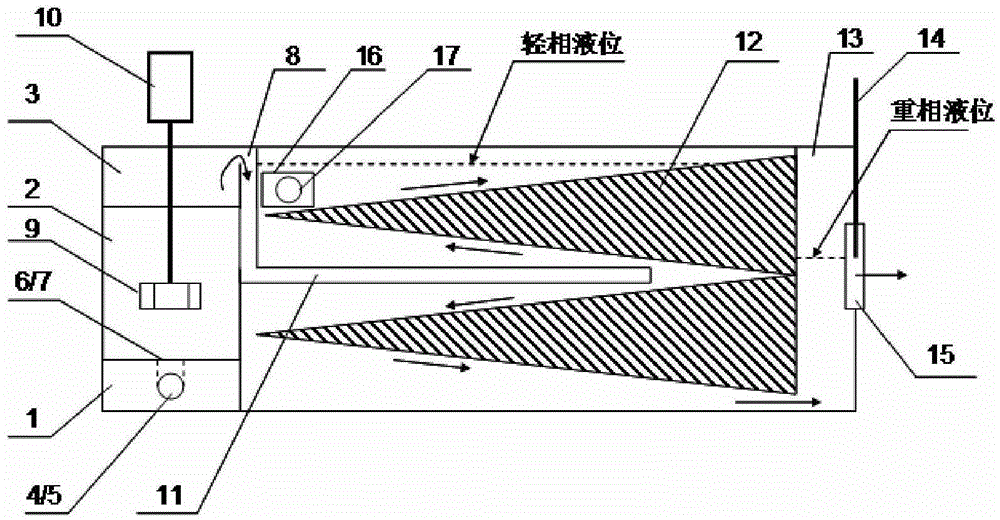

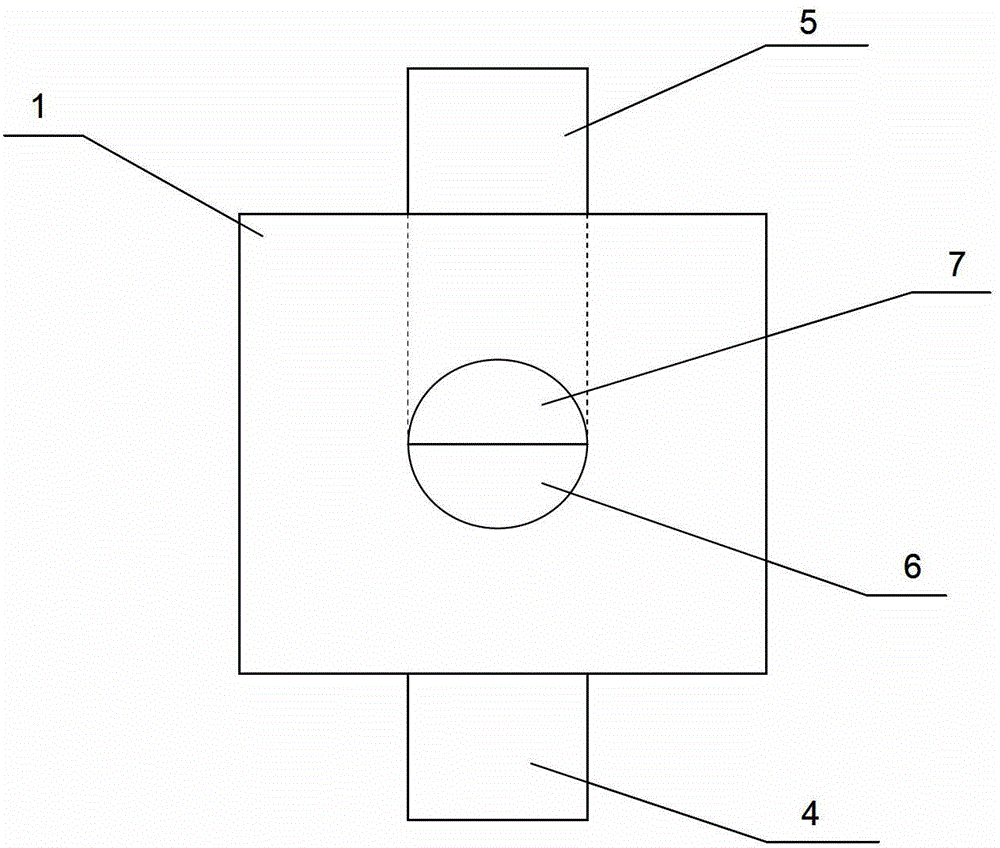

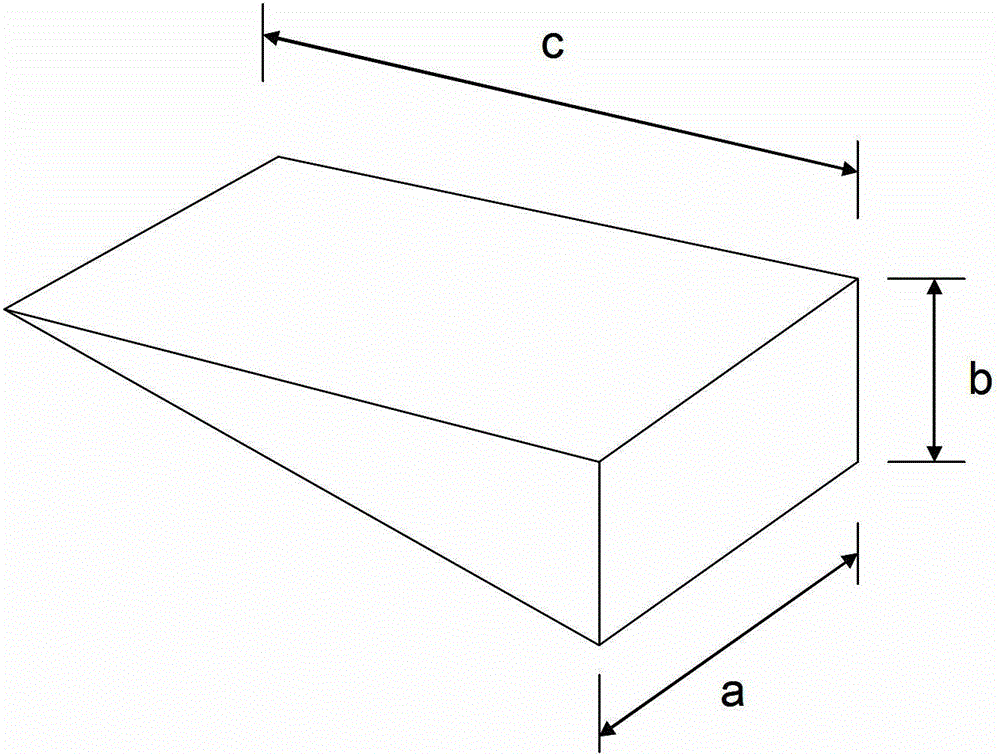

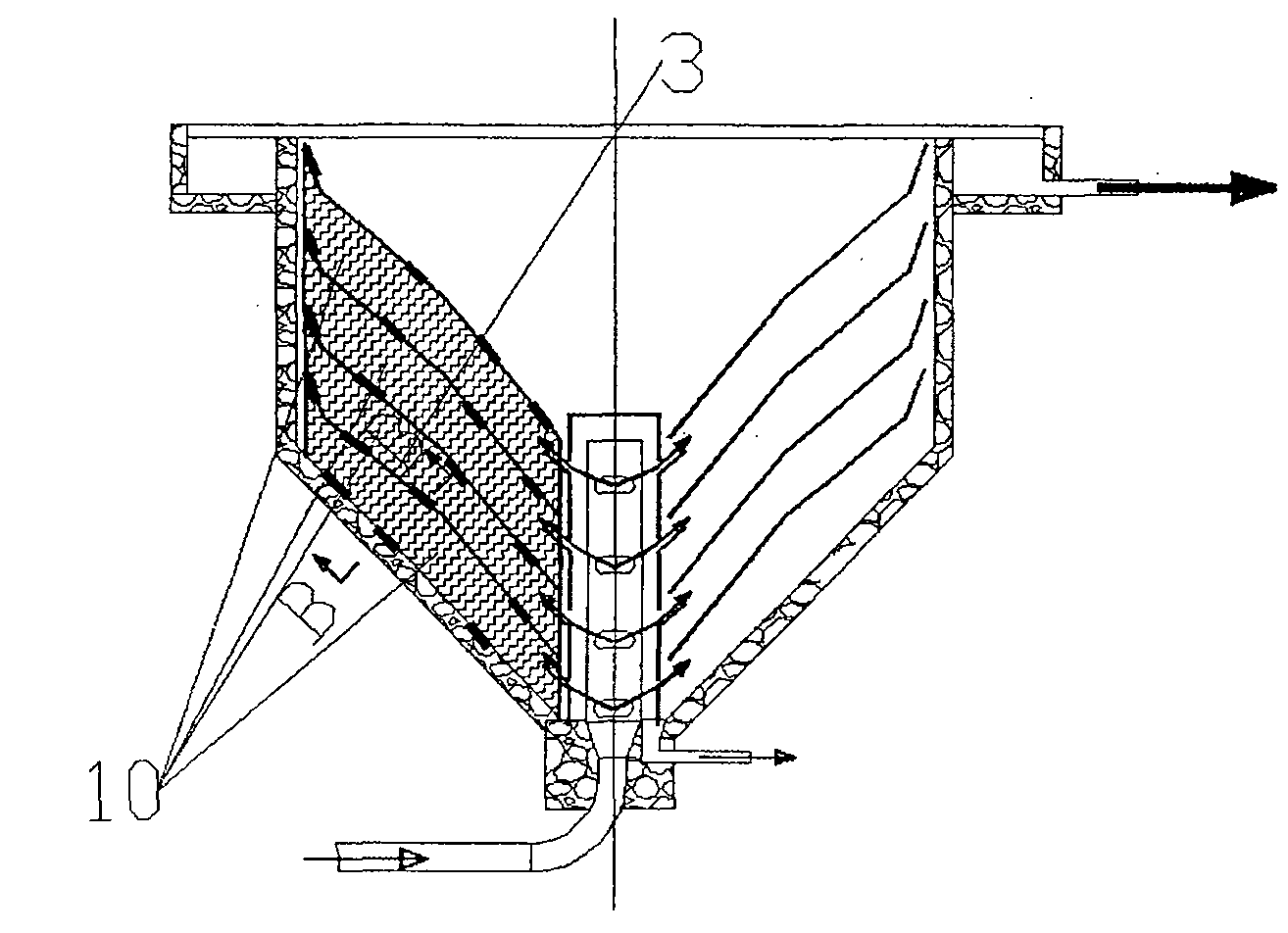

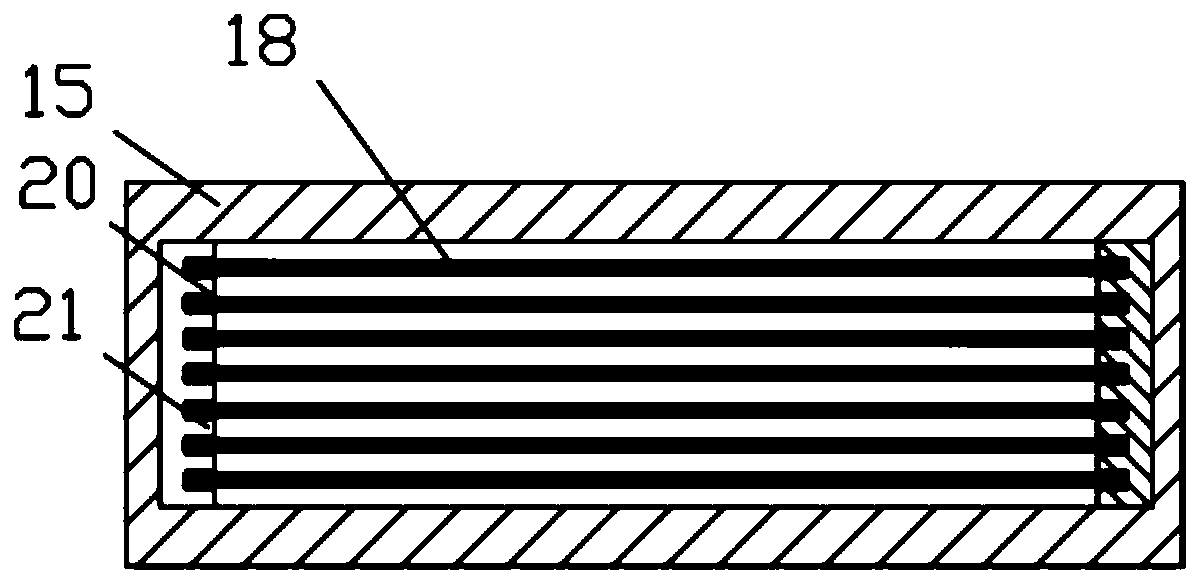

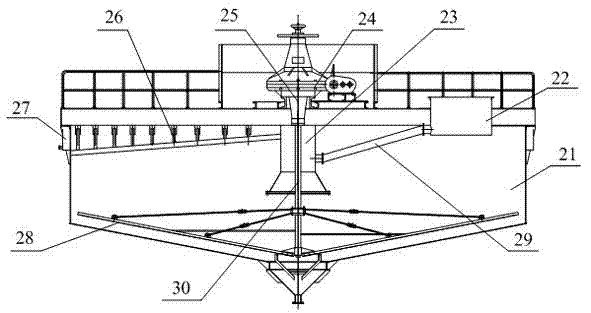

Liquid-liquid extraction mixer-settler and extraction method and application thereof

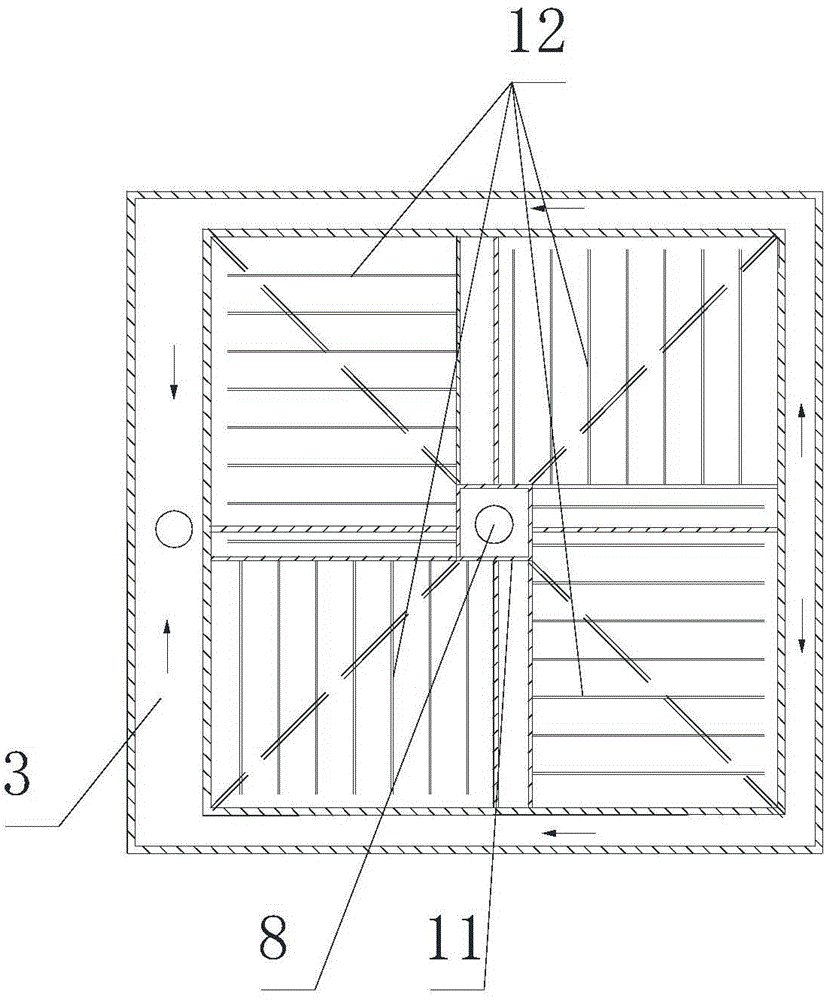

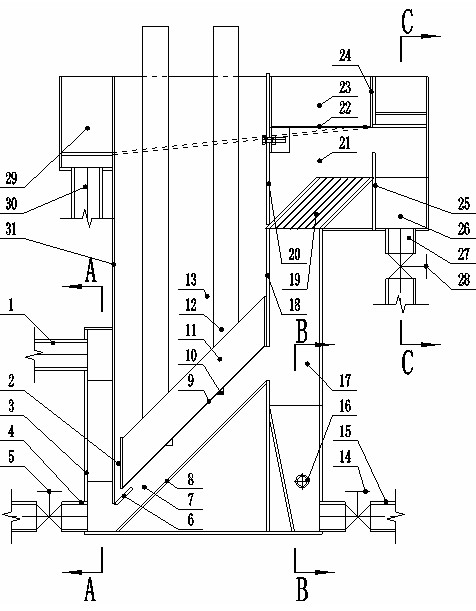

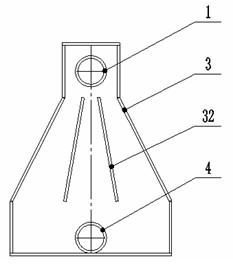

InactiveCN103120863AIncrease the settlement areaReduce holdupLiquid solutions solvent extractionSingle stagePhase splitting

The invention relates to a liquid-liquid extraction mixer-settler and an extraction method and an application thereof. The mixer-settler comprises a mixing chamber and a clarifying chamber, wherein the side in the clarifying chamber near the mixing chamber is provided with a guide pipe which extends to the tail end of the clarifying chamber from an outlet of the mixing chamber; and at least the upper part or the lower part of the guide pipe in the clarifying chamber is transversely and fixedly provided with a wedge-shaped body. As the upper part and / or the lower part of the guide pipe in the clarifying chamber is fixedly provided with the wedge-shaped body, not only is the storage amount of organic phases in the settling chamber reduced, but also a large light-heavy two-phase settling area is provided so that the clarifying phase-splitting time is prolonged, and the clarifying separation effect is remarkable for an easily-emulsifying system or a system with larger viscosity; and the mixer-settler provided by the invention can be used for single-stage continuous extraction operation or multi-stage series-connected countercurrent continuous extraction operation.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

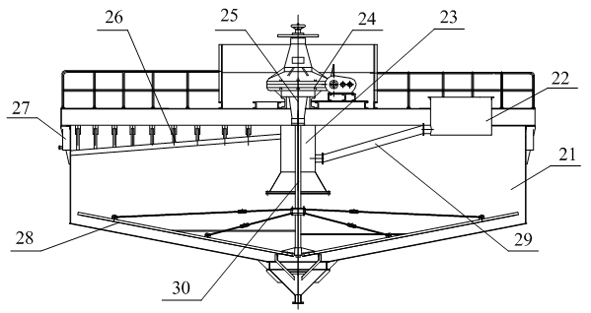

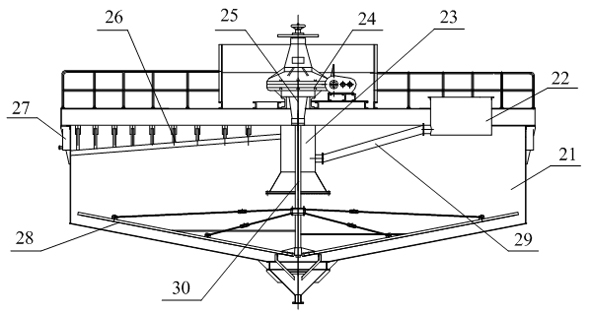

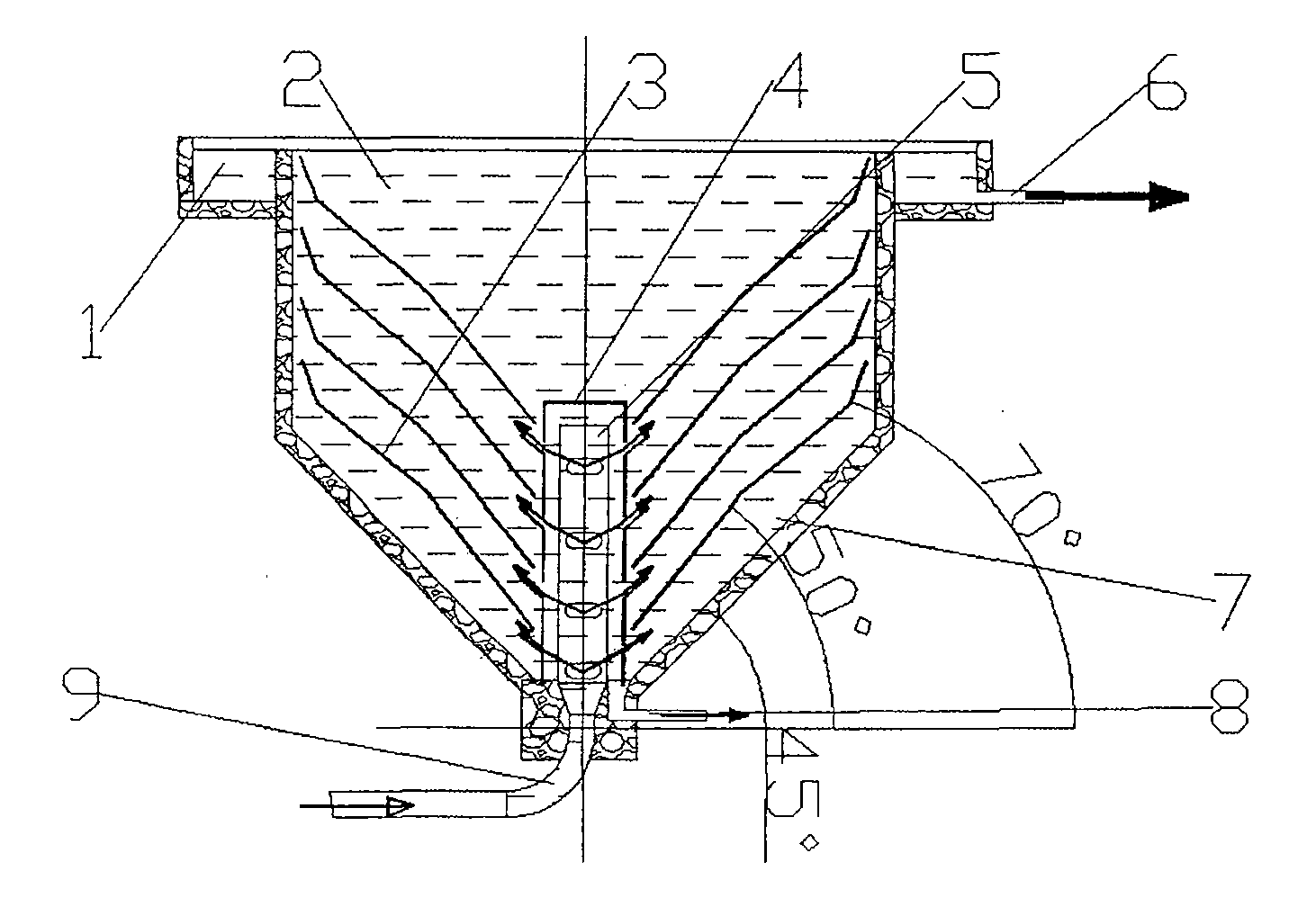

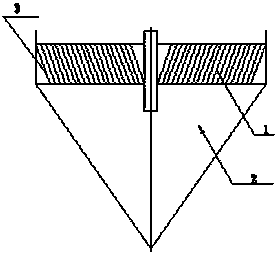

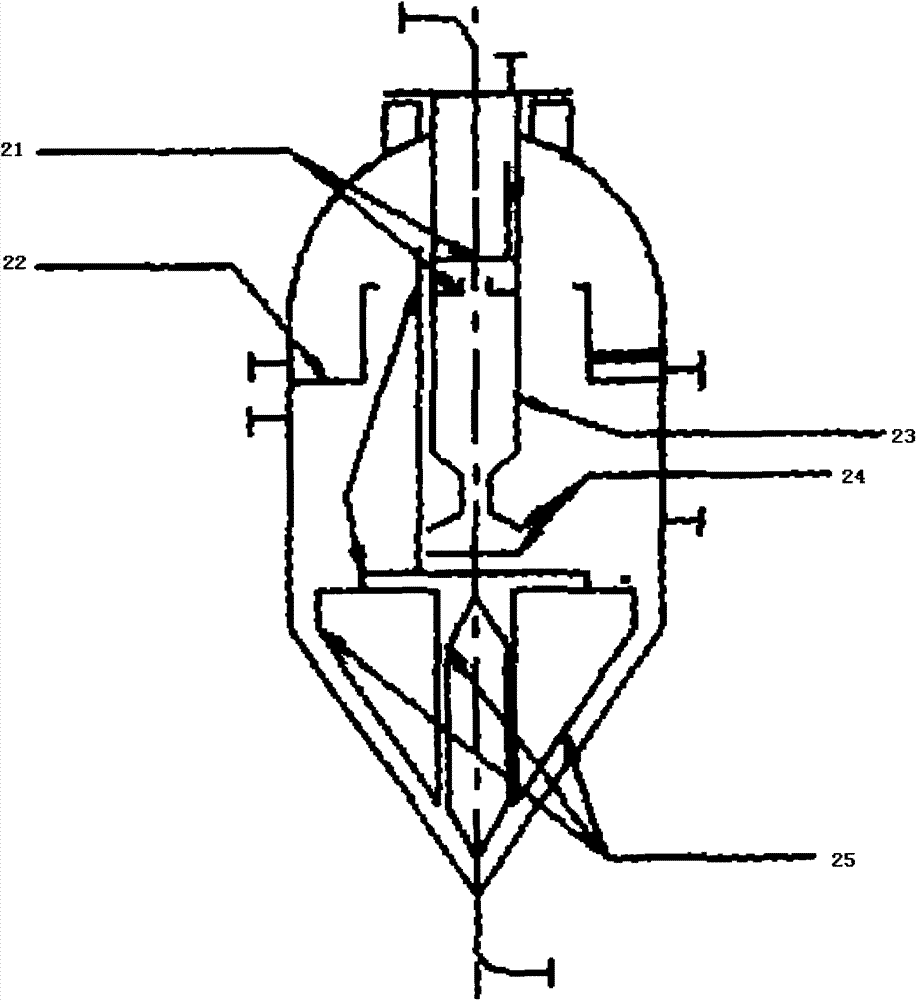

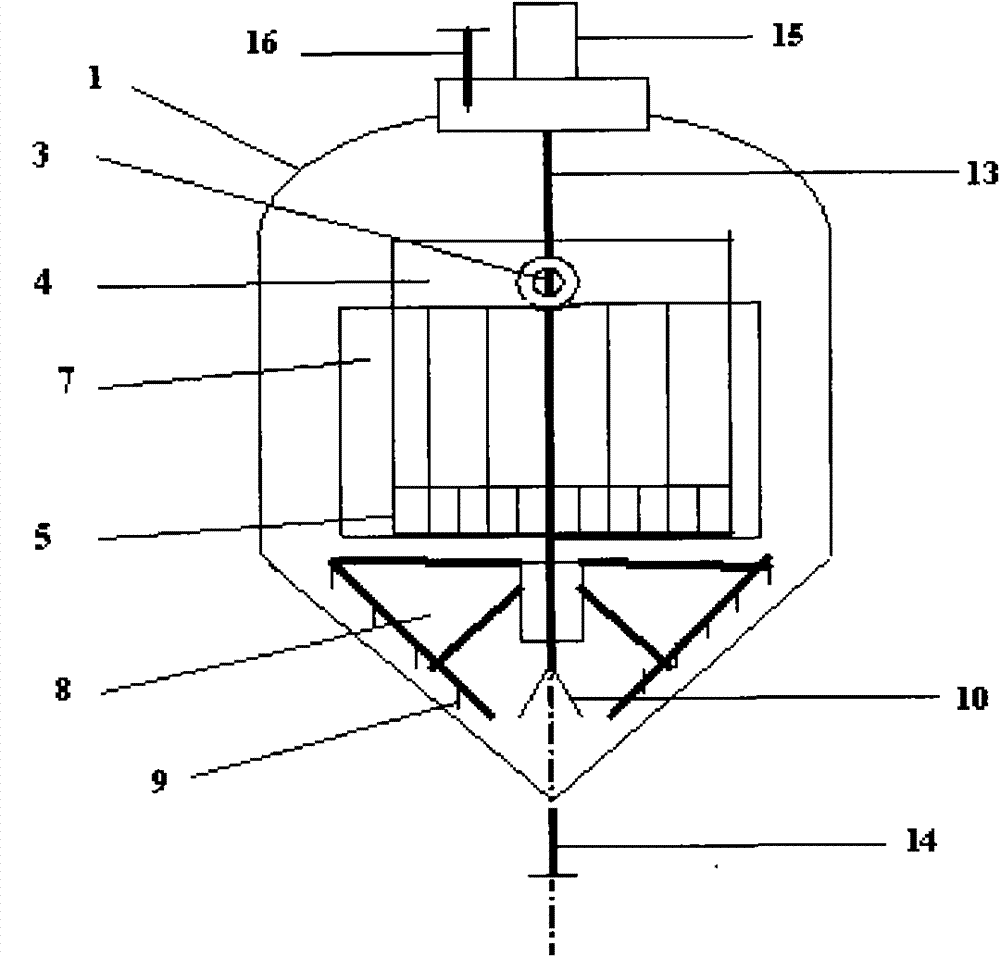

Continuous settling tank

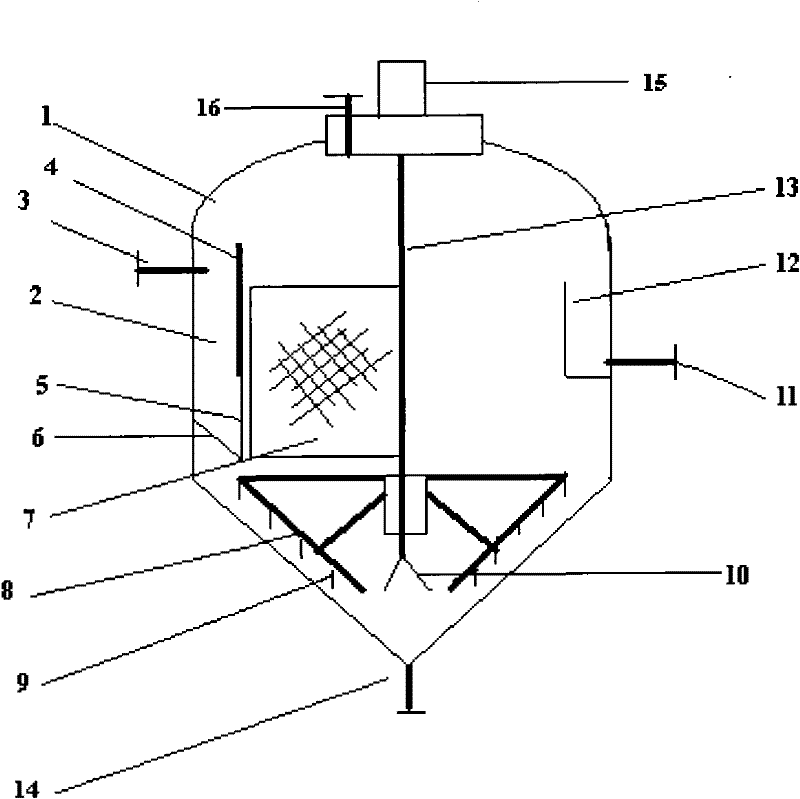

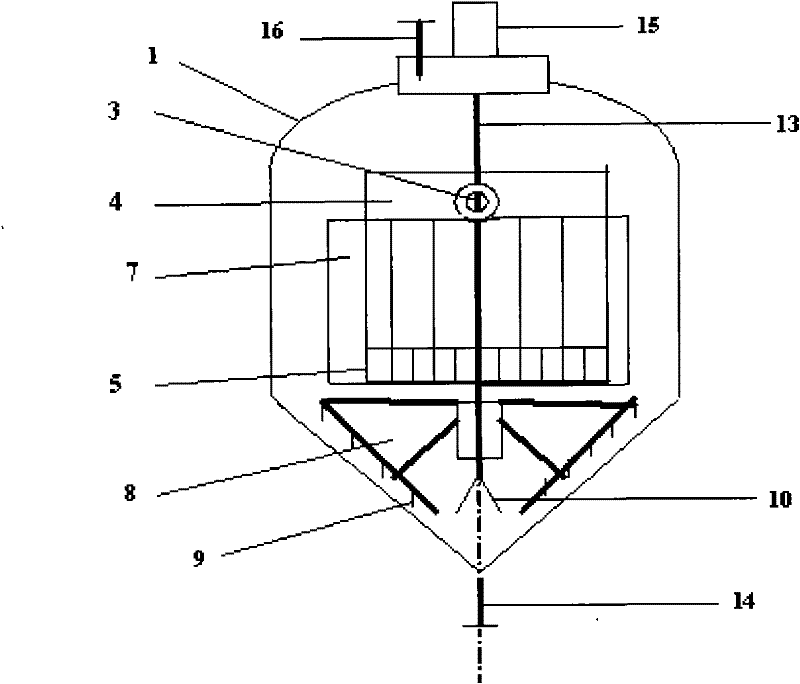

InactiveCN102225251AHigh speedReduce lossesLiquid degasificationLiquid separationInterior spaceEngineering

The invention discloses a continuous settling tank which comprises a shell, wherein the shell is provided with a circular cylinder at the upper part and a conical cylinder at the lower part; an overflow weir is arranged in the circular cylinder; an underflow outlet is arranged at the bottom of the conical cylinder; an arch-shaped feeding slot is arranged in the circular cylinder of the shell; the arch-shaped feeding slot comprises the inner side wall of the circular cylinder, a flat wall plate, a grid distributing plate and a baseboard; the grid distributing plate is arranged under the flat wall plate; upper and lower ends of the grid distributing plate are respectively fixedly connected to the flat wall plate and the baseboard; a plurality of porous guiding vanes are symmetrically and obliquely arranged outside the flat wall plate; gaps are reserved between the guiding vanes and the flat wall plate; and a rotary rake is arranged on the conical cylinder at the lower part of the shell. By using the continuous settling tank provided by the invention, the maximum settling area is supplied as much as possible, an interior space of equipment is efficiently utilized, a settling separating effect is improved, and the loss of solid materials such as catalyst can be reduced.

Owner:TIANJIN UNIV +1

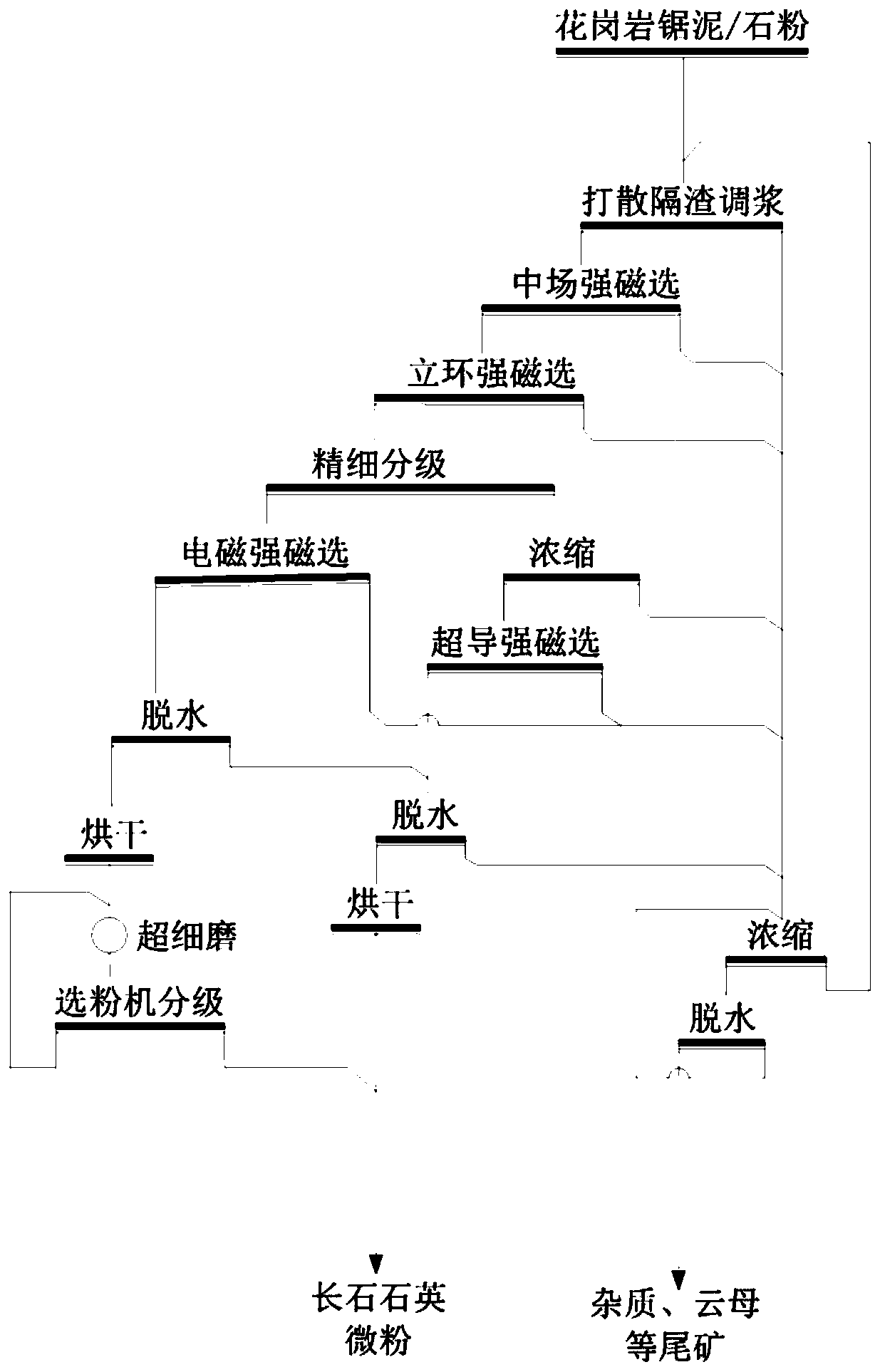

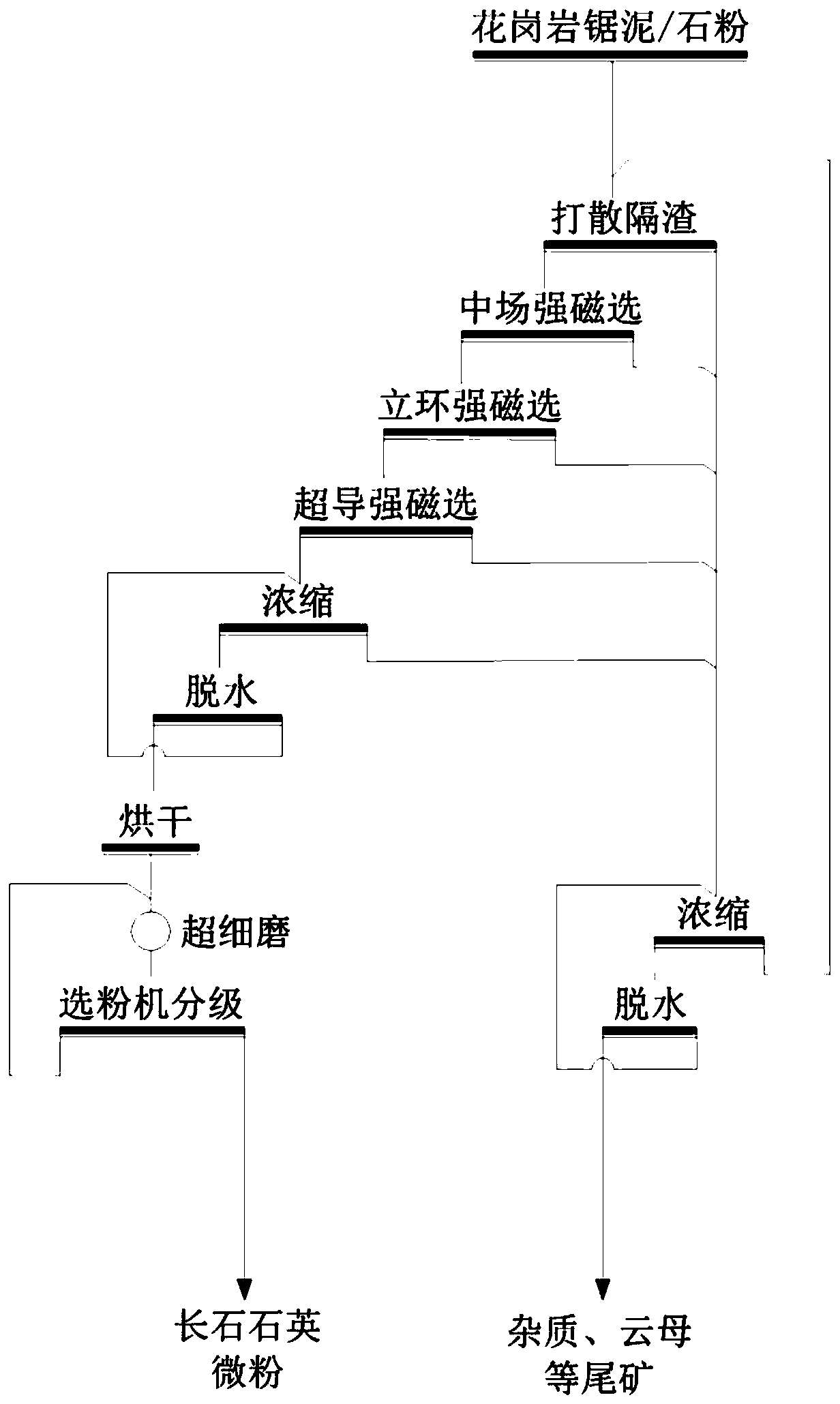

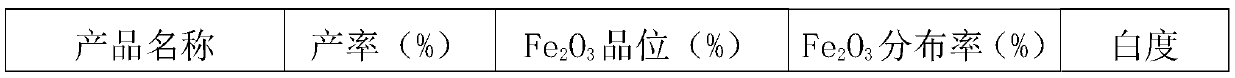

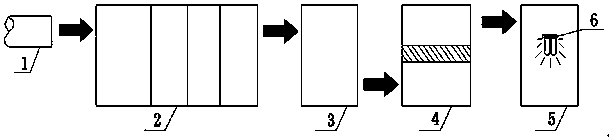

Method for preparing superfine high-whiteness micro powder by removing impurities from granite fine-grained stone powder in full-grained manner

ActiveCN110743685ARealize impurity removal and whiteningSolve magnetic separation iron removalMagnetic separationGrain treatmentsSlagImpurity

The invention provides a method for preparing superfine high-whiteness micro powder by removing impurities from granite fine-grained stone powder in a full-grained manner. The method comprises the following steps: (1) taking granite saw mud or stone powder as raw ore, firstly performing slag separation and classification on the raw ore to realize material scattering and removal of oversize particles, and then performing two-stage magnetic separation to remove mechanical iron impurities, mica and weak magnetic substances to obtain a non-magnetic substance; (2) performing fine classification onthe non-magnetic substance in the step (1) according to the particle size requirement to obtain a fine-grained product and a coarse-grained product; (3) performing high-field-intensity magnetic separation on the coarse and fine products respectively; and (4) preparing micro powder. According to the method, a pollution-free environment-friendly physical technology and a low-temperature superconducting magnetic separation technology are adopted, so that the technical problems of magnetic separation and iron removal of fine particles and energy conservation and consumption reduction of superfinepowder prepared by non-metal ore are solved, and large-scale consumption and high-value utilization after impurity removal and whitening of the granite saw mud and stone powder are realized. Comparedwith a traditional impurity removal and whitening process, the method has the advantages that the product whiteness is improved by 15 20 degrees, the yield is improved by 23 25%, and compared with a traditional process for preparing powder from ore, crushing and ore grinding are not needed.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

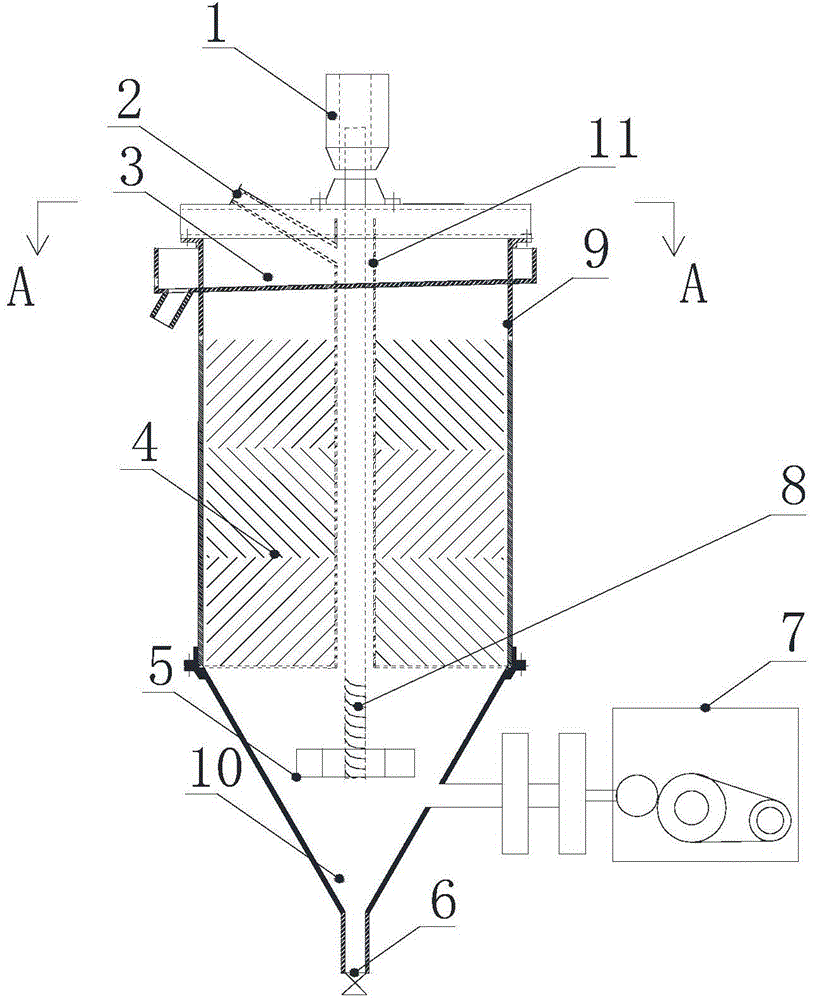

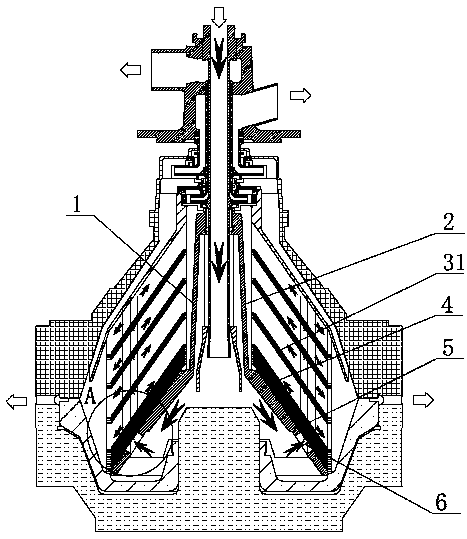

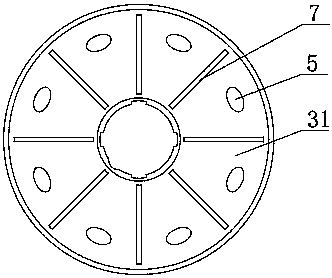

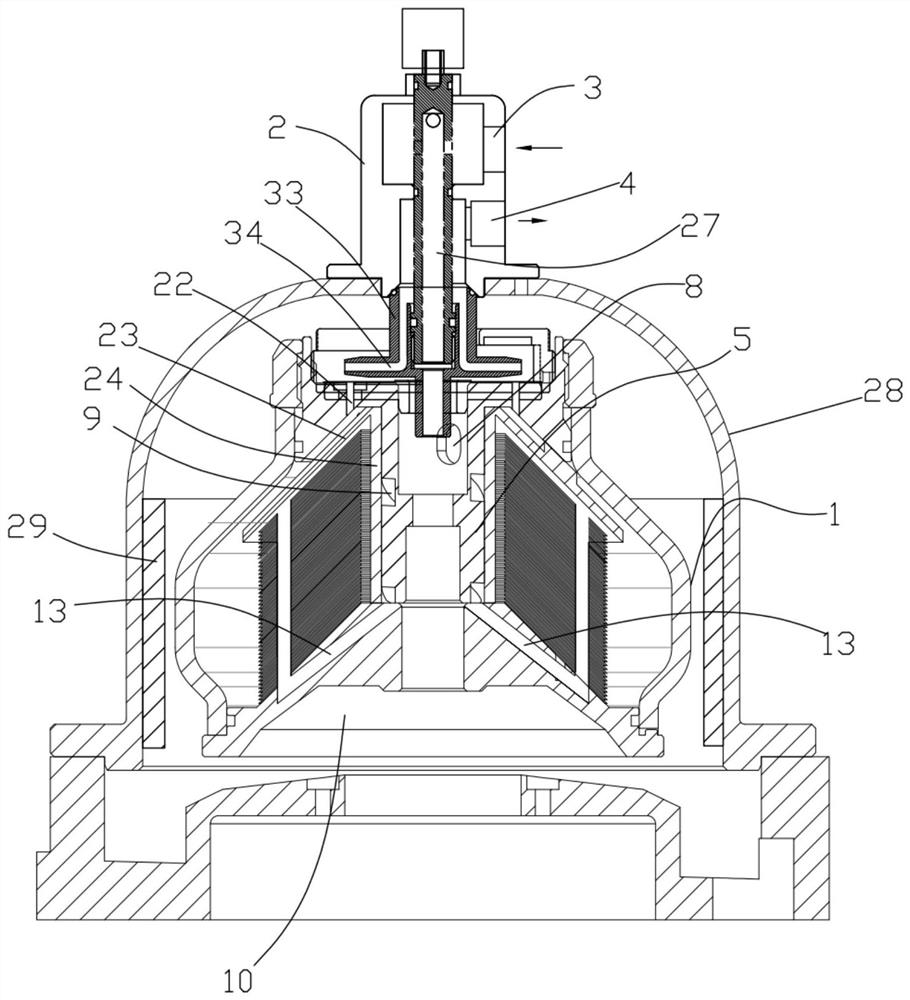

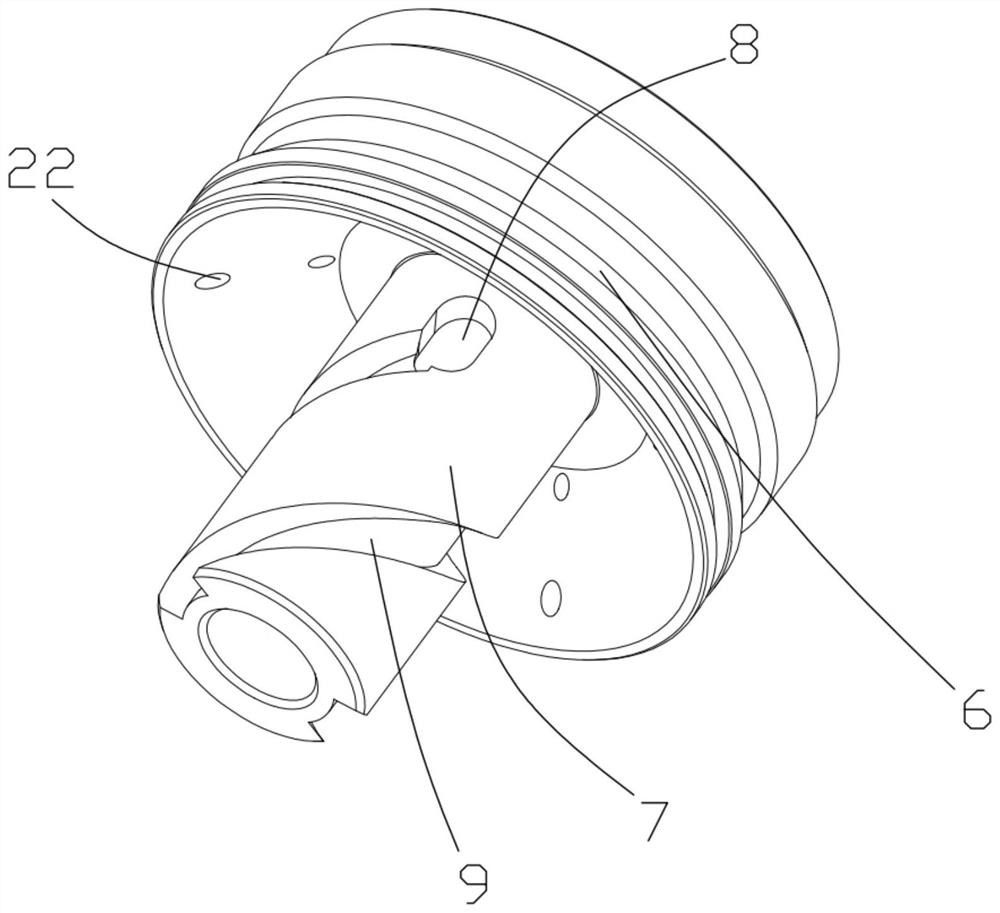

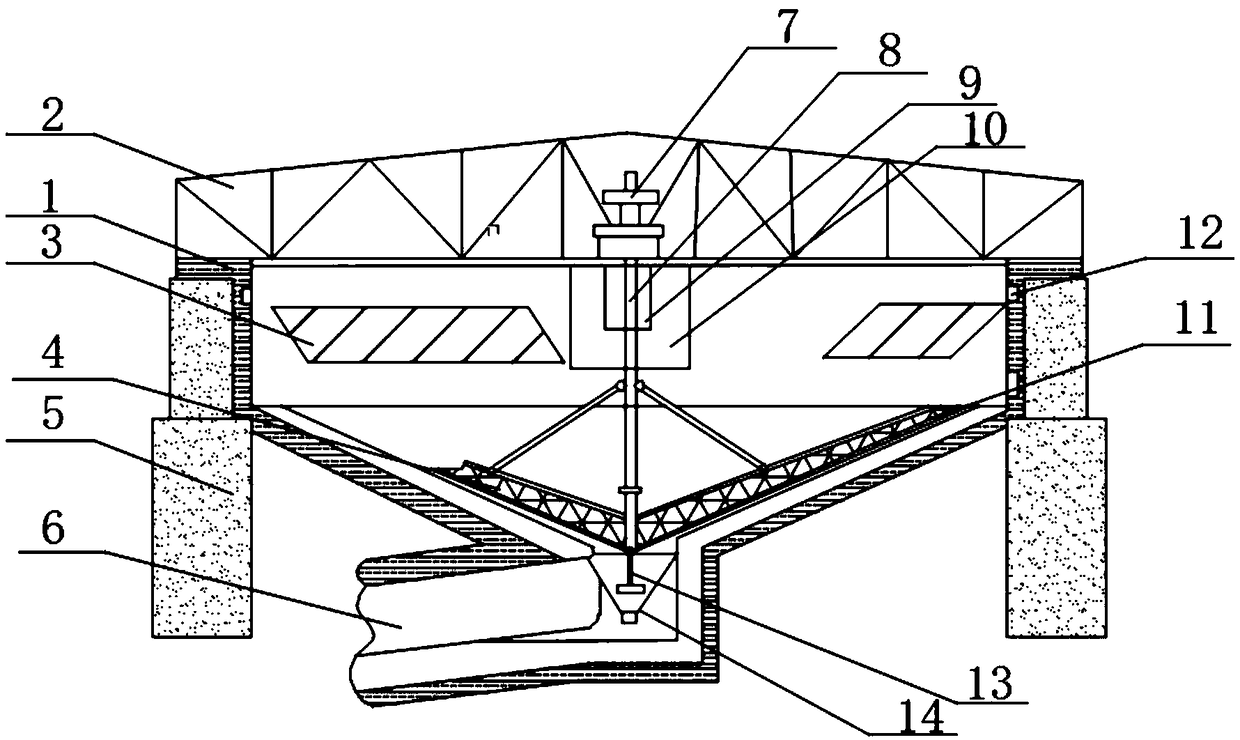

Comprehensive force field multithread gravity concentrator

The invention discloses a comprehensive force field multithread gravity concentrator. The gravity concentrator comprises a gravity concentrator main body, a comprehensive force field precipitation separation area, a driving device, a rotation device and a pulsation device, wherein the rotation device and the dithering device are arranged at the lower part of the gravity concentrator main body, and enable the lower part of the gravity concentrator main body to form the comprehensive force field precipitation separation area under the combined action of a turbulence fluid field and a pulsation force field; the rotation of the rotation device is driven by the driving device; a feeding opening is formed in the central area at the top of the gravity concentrator; the feeding opening is communicated with the comprehensive force field precipitation separation area at the lower part through a central feeding pipe; an underflow opening is formed in the bottom of the comprehensive force field precipitation separation area; the upper part of the comprehensive force field precipitation separation area is communicated to the overflow dam part at the top of the gravity concentrator main body through an upstream passage encircling the central feeding pipe; baffle board components are uniformly arranged in the upstream passage to form an inclined board settling area. The gravity concentrator has the advantages that the gravity concentrator is high in sorting accuracy, stable and reliable in work, low in energy consumption, and environment-friendly.

Owner:CENT SOUTH UNIV

Gravity classification and immersive screen combined classifying method and device utilizing same

InactiveCN102527499AImprove grading effectReduce power consumptionWet separationEngineeringSmall footprint

Disclosed are a gravity classification and immersive screen combined classifying method and a device utilizing the same. Interference settlement, shallow settlement and screening classification are combined by arrangement of immersive screens, a water raise pipe and inclined plates. Materials are classified by a first screening classification chamber, an interference settlement classification chamber, a shallow settlement classification chamber and a second screening classification chamber in a multiple stage manner, so that classification effect of the materials is enhanced. Since fluid pressure provides power for classification of the materials, classification effect is enhanced further while power loss is saved. The adaptability of the device to flow states of fed materials is improvedgreatly. The usage of raise water is reduced, and the unit area treatment capacity and classification efficiency of the device are improved. The overflow grain size is controlled severely. The devicehas the main function of classifying and the auxiliary function of screening, and is simple and compact in structure, small in floor area, simple in operation method and wide in practicability.

Owner:CHINA UNIV OF MINING & TECH

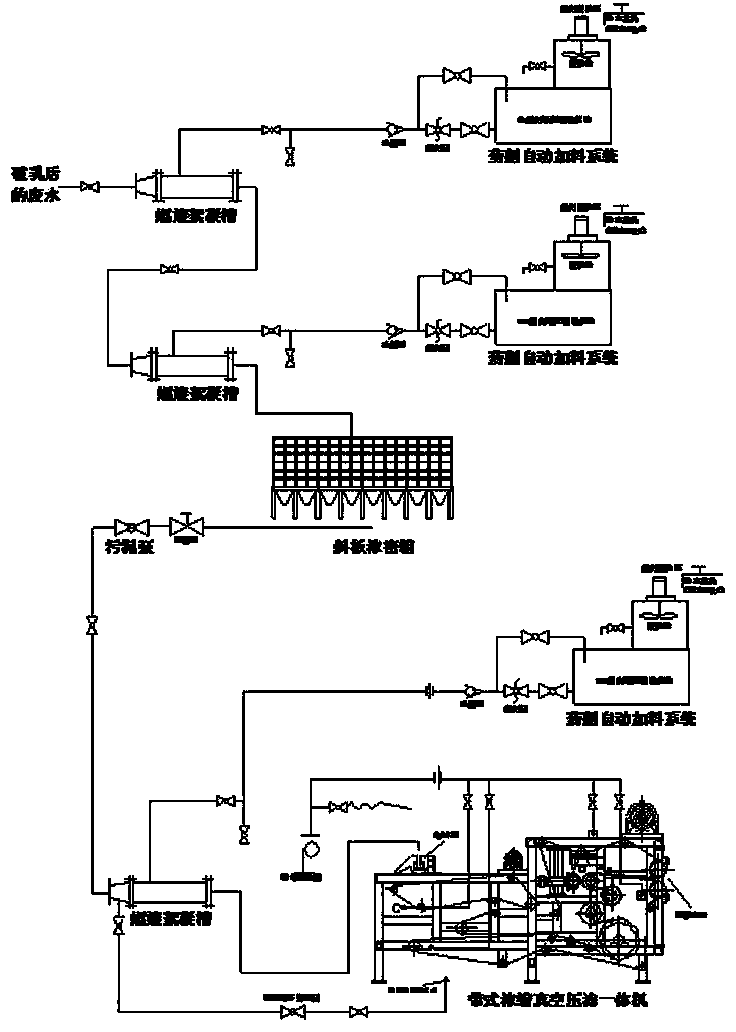

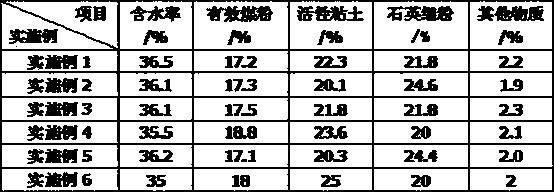

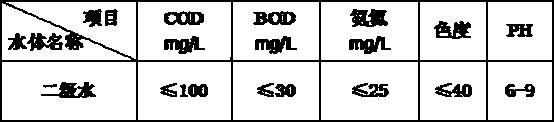

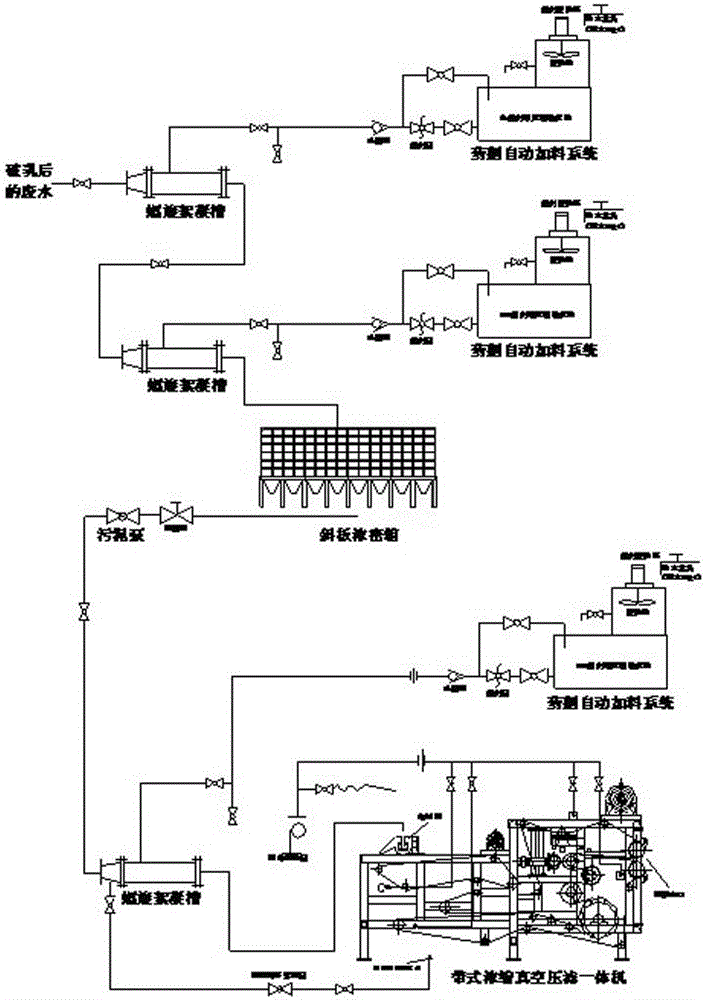

Mixed type foundry waste sand wet reclamation wastewater processing method

ActiveCN103351065ASolve the disadvantages of being difficult to effectively dehydrateGuaranteed uptimeMultistage water/sewage treatmentWater useFoundry

The invention provides a mixed type foundry waste sand wet reclamation wastewater processing method. Firstly, wastewater is demulsified, and large suspended matters in the wastewater are flocculated in a spiral flocculating tank by virtue of an inorganic flocculating agent; then small suspended matters are flocculated by virtue of an organic flocculating agent; through standing sedimentation in an inclined tube sedimentation tank, a flocculation layer forming at the bottom in a condensed manner is extracted through a sludge pump at the bottom of the sedimentation tank; the organic flocculating agent is secondarily used, and finally, a band type concentration-vacuum-filter pressing all-in-one machine is used for treatment, so that the water content of sludge discharged at an outlet of a filter cake of the band type concentration-vacuum-filter pressing all-in-one machine is less than 40%; therefore, supernate overflowing from the inclined tube sedimentation tank and clear water from a clear water outlet of the band type concentration-vacuum-filter pressing all-in-one machine can achieve the requirement for production cycle water and the standard for direct discharge.

Owner:广西兰科资源再生利用有限公司

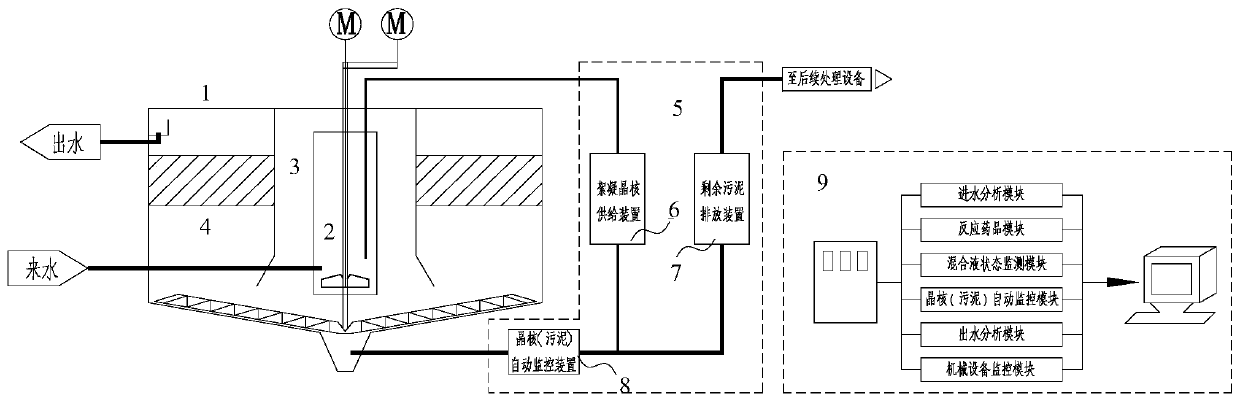

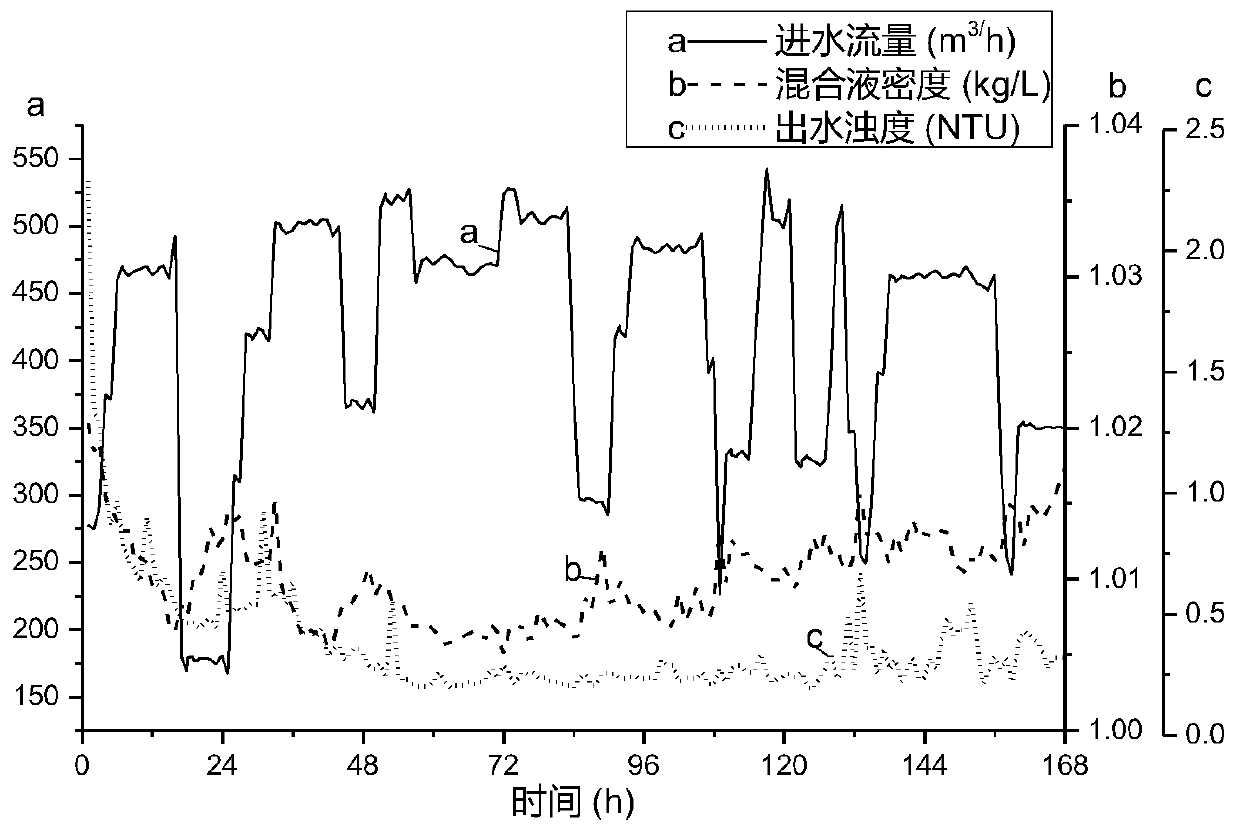

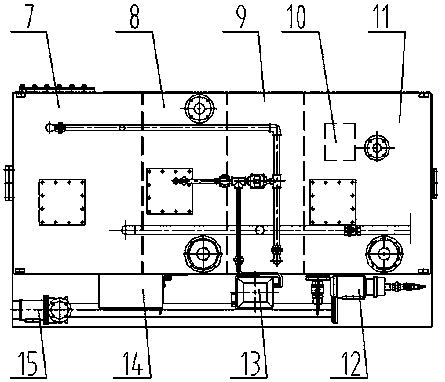

Forced reaction coagulation clarification system capable of realizing intelligent regulation and control

PendingCN110316801APromotes crystal growthStable crystal growthWater treatment parameter controlWater/sewage treatment by flocculation/precipitationStable stateFlocculation

The invention discloses a forced reaction coagulation clarification system capable of realizing intelligent regulation and control. The system comprises a clarification tank, a forced coagulation regulation and control unit and an analysis unit and is particularly applicable to the operation condition of frequently fluctuant water inflow. According to the system operation condition monitored and collected in real time by each functional module, the analysis unit accurately calculates the sludge generation amount of the clarification tank and the flocculation reaction degree of mixed liquid ina reaction area, analyzes the real-time operation state of the clarification tank and takes corresponding regulation and control measures. Through the forced coagulation regulation and control unit, the flocculation crystal nucleus quantity and sludge discharge amount of a forced coagulation reaction are accurately regulated and controlled, an optimized forced coagulation reaction environment is constructed, the growth and adsorption precipitation of flocculation crystal nuclei are effectively controlled, and it is ensured that the physical and chemical properties of floc in the reaction areastay in a good stable state. The system realizes automatic control over the intelligent and precise forced coagulation reaction environment, automatic control over the discharge of residual sludge, automatic control over a flushing device and the like and ensures the stable operation of the clarification tank, the effluent quality of the system is improved, and the operation benefits of the systemare increased.

Owner:XIAN TPRI WATER & ENVIRONMENTAL PROTECTION

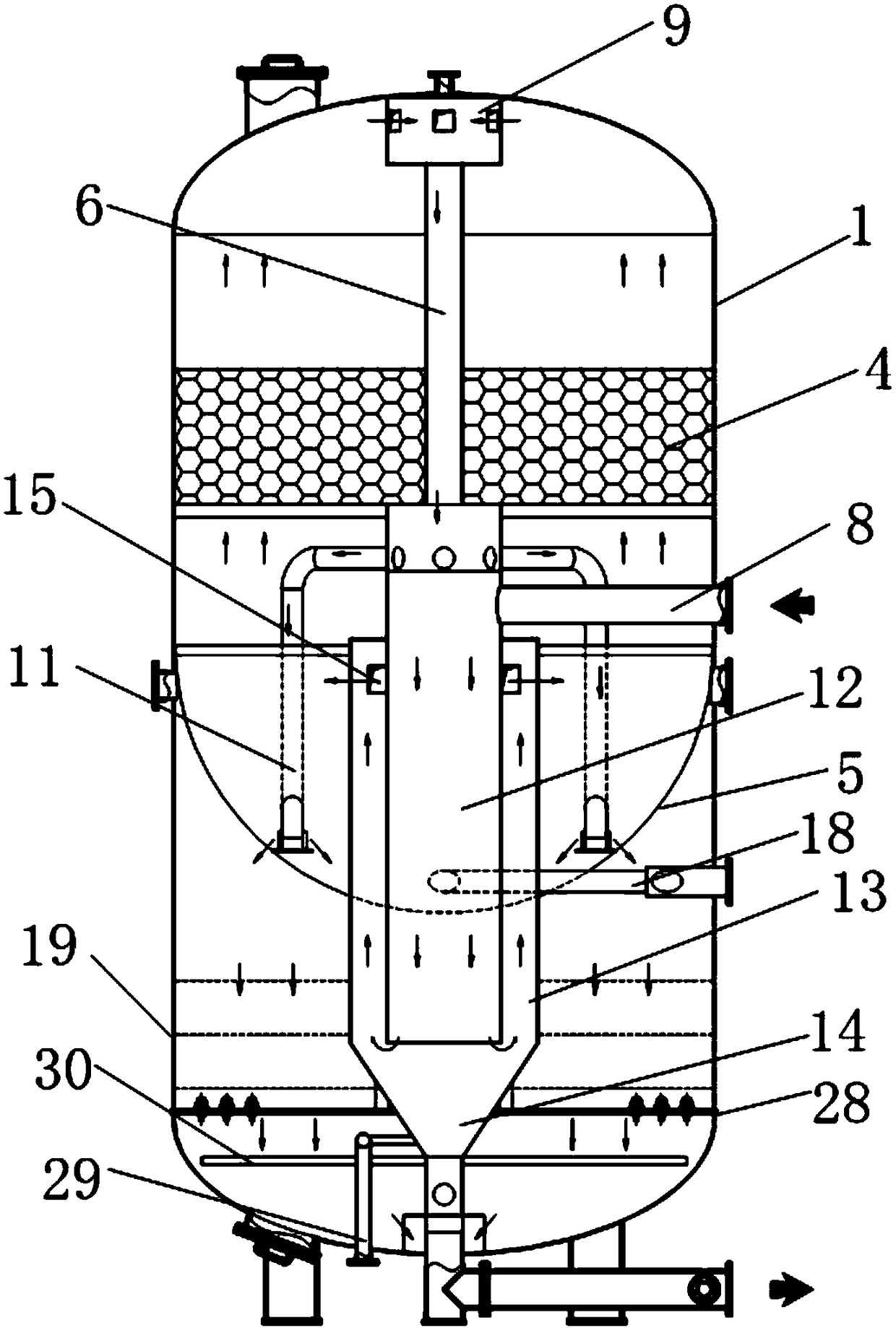

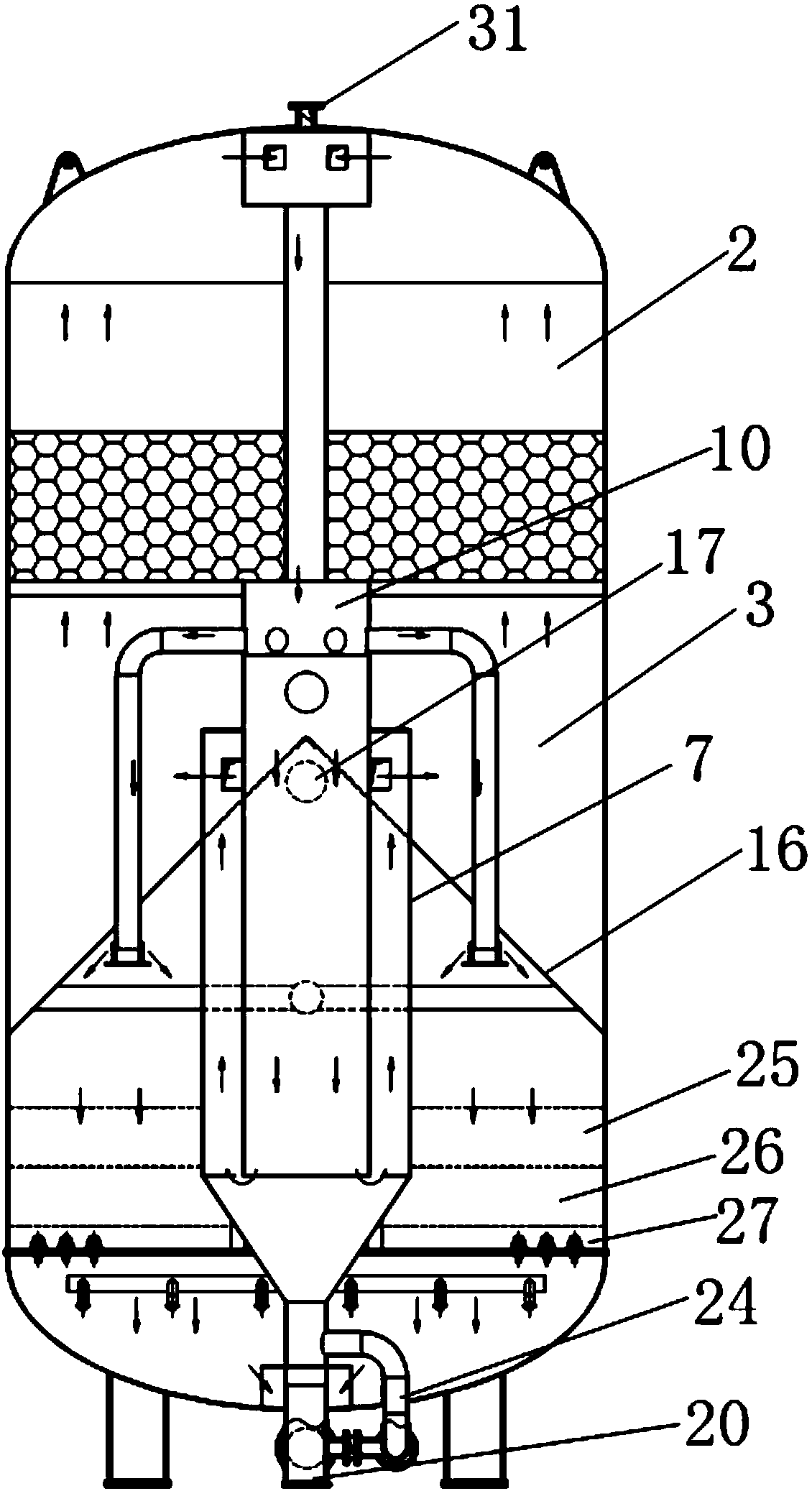

Integrated oil and turbidity removing device

PendingCN108483751AIncrease volumeImprove the effect of flocculation and sedimentationFatty/oily/floating substances removal devicesTreatment involving filtrationFlocculationSlag

The invention discloses an integrated oil and turbidity removing device which comprises a device body; a clarification zone is arranged at the upper part of the device body, and a mud settling zone isarranged at the lower part; symmetrical mud collecting hoppers are arranged under the mud settling zone; a flocculation reaction chamber is divided into a first flocculation reaction chamber and a second flocculation reaction chamber; the first flocculation reaction chamber is embedded in the second flocculation reaction chamber and is communicated with the second flocculation reaction chamber through the open lower end of the first flocculation reaction chamber; a slag collecting hopper is connected under the second flocculation reaction chamber; a water outlet is formed above the second flocculation reaction chamber and is close to the symmetrical mud collecting hoppers; the symmetrical mud collecting hoppers comprise two symmetrical mud hopper cone plates; an included angle between each of the mud hopper cone plates and a horizontal plane is 45 degrees; a roof structure with an included angle of 90 degrees is formed between the two mud hopper cone plates. The integrated oil and turbidity removing device disclosed by the invention has the benefits that all the functions of a chemical oil remover and a high-speed filter are combined, and the floor area is reduced.

Owner:江苏德科环境科技有限公司

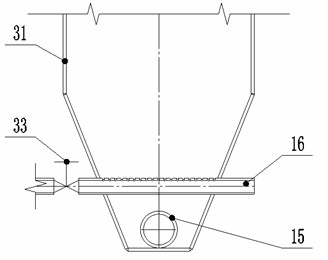

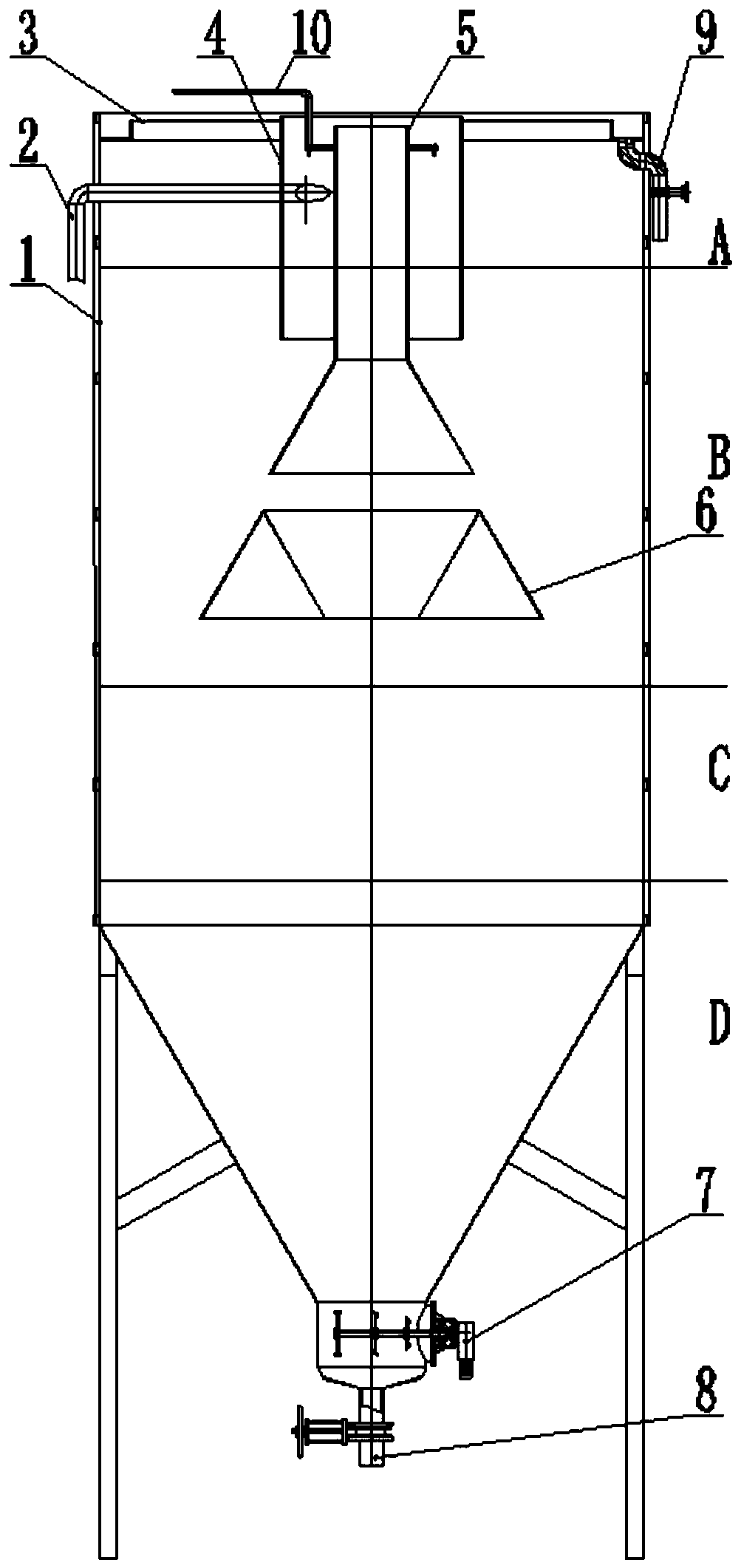

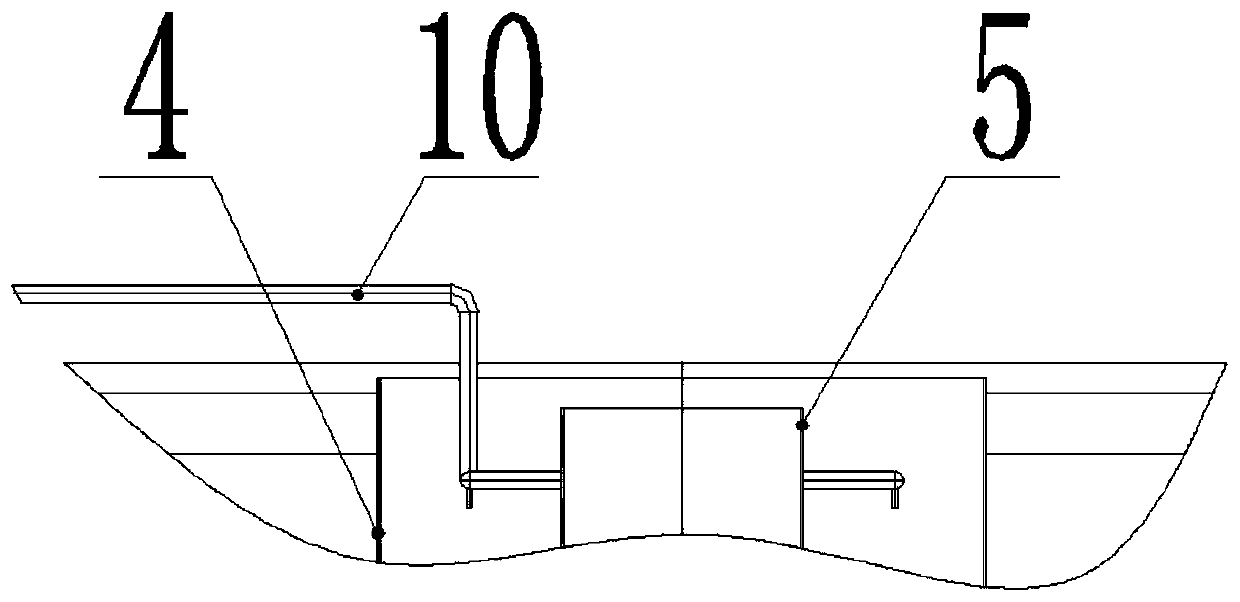

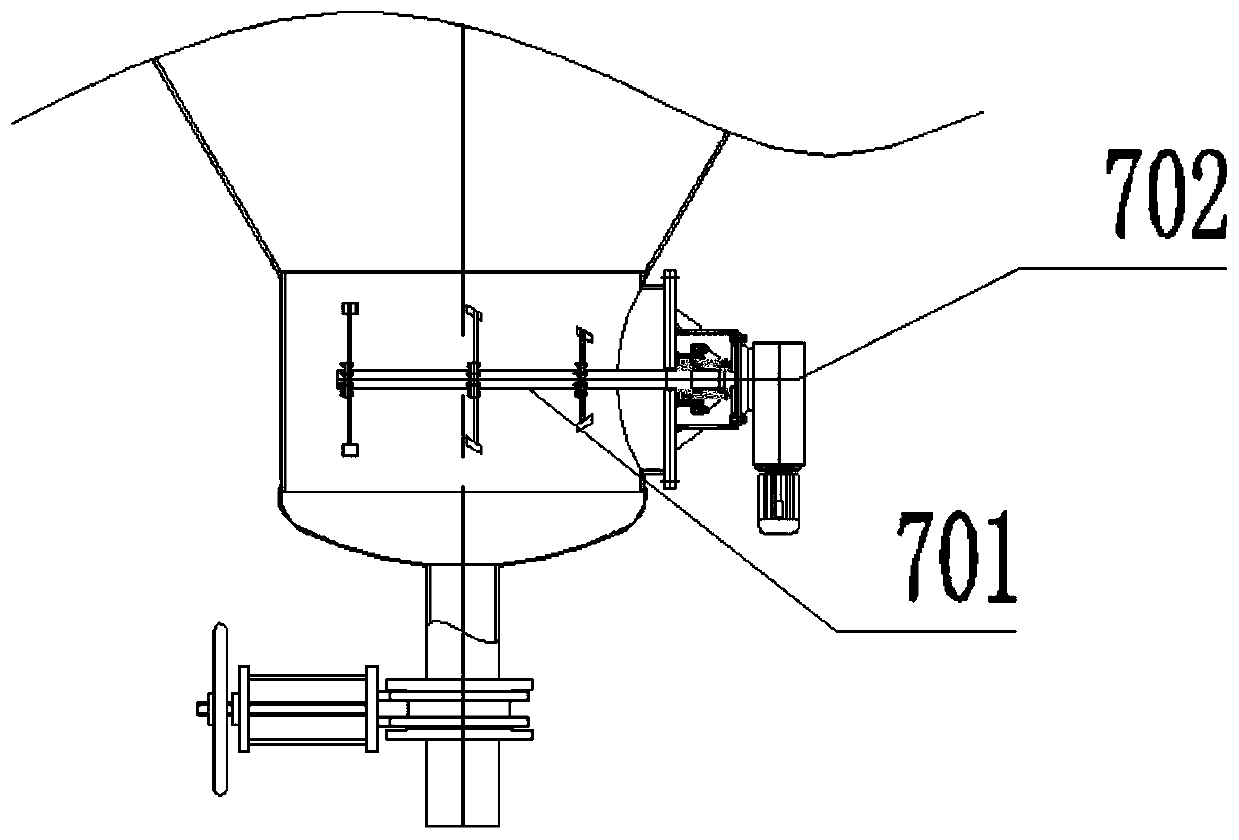

Deep-cone thickening sand bin with fluidized sand discharging device

PendingCN110152358AAccelerate the speed of flocculation and agglomerationReduce concentrationSettling tanks feed/dischargeCentrifugal force sediment separationEngineeringTailings

The invention relates to a deep-cone thickening sand bin with a fluidized sand discharging device. The deep-cone thickening sand bin with a fluidized sand discharging device comprises a sand bin body,a material feeding pipe, a flocculant inlet pipe, an overflow tank, a material feeding well, a circulation well, an annular guide cone and a stirring fluidization device, wherein the overflow tank isfixedly connected to the top of the inner wall of the sand bin body, and communicates with a supernatant return pipe, the material feeding well is disposed at the center of the top of the sand bin body, and is fixedly connected with the sand bin body, and the circulation well is disposed in the material feeding well, and is fixedly connected with the material feeding well; a material feeding zoneis formed between the material feeding well and the circulation well, the material feeding pipe communicates with the material feeding zone, and the annular guide cone is disposed directly below thecirculation well, and is fixedly connected with the inner wall of the sand bin body; and the diameter of the top of the annular guide cone is the same as the diameter of the circulation well, a material outlet is formed in the bottom of the sand bin body, and the stirring fluidization device is fixedly connected with the mouth outlet. A special flow field is formed after tailings is introduced into the sand bin, no consumption of waterpower and gas power is generated, the fluidization effect is good, and it is ensured that the mortar concentration and the thickening effect are not reduced.

Owner:金诚信矿山工程设计院有限公司

Sewerage pretreatment method and denitrification anaerobic hydrolytic precipitation pool

InactiveCN101475291ALow costLow suspended solids in effluentTreatment with anaerobic digestion processesMultistage water/sewage treatmentPretreatment methodBiological filter

The invention discloses a sewage pretreatment method and a denitrification-anaerobic hydrolysis sedimentation tank and relates to a sewage pretreatment method and a denitrification-anaerobic hydrolysis-acidation device. The method and the sedimentation tank solve the problems that the prior sewage pretreatment method has poor treatment effect and high cost and the sludge in the prior denitrification-anaerobic hydrolysis sedimentation tank floats upwards to influence water quality. The method comprises the following steps: firstly, treating the sewage through a coarse grille, a middle grille, a rotating drum type thin grille and a rotational flow grit chamber; and secondly, hydrolysis-acidation treatment, namely, realizing pretreatment of the sewage. The denitrification-anaerobic hydrolysis sedimentation tank consists of an effluent weir, a top cap, a honeycomb inclined pipe component, a clear water zone, a suspended silt zone, a mud bucket, a water inlet pipe and a mud pipe. The method has good treatment effect and low cost for sewage pretreatment; and the denitrification-anaerobic hydrolysis sedimentation tank solves the problem that the sludge floats upwards to influence the water quality. The invention provides a pretreatment method for an aeration biological filter, and can ensure stable operation of the biological filter and the water quality of the yielding water.

Owner:HARBIN INST OF TECH

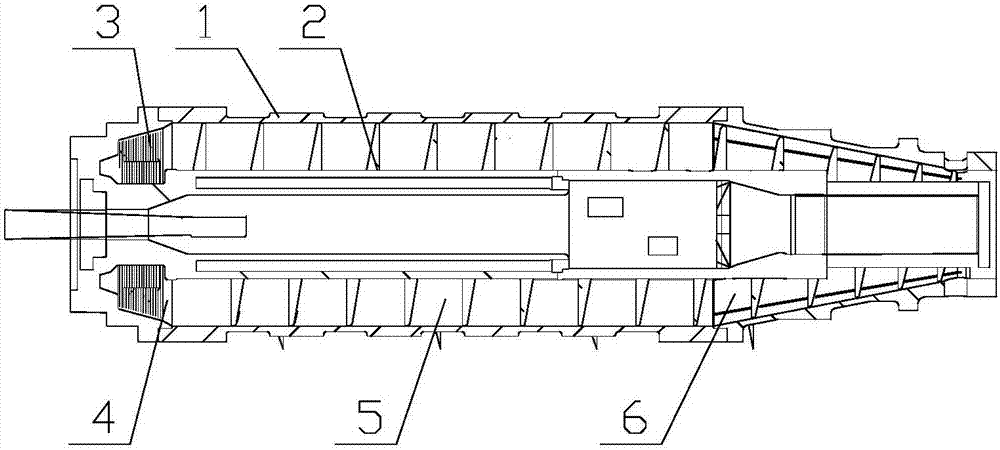

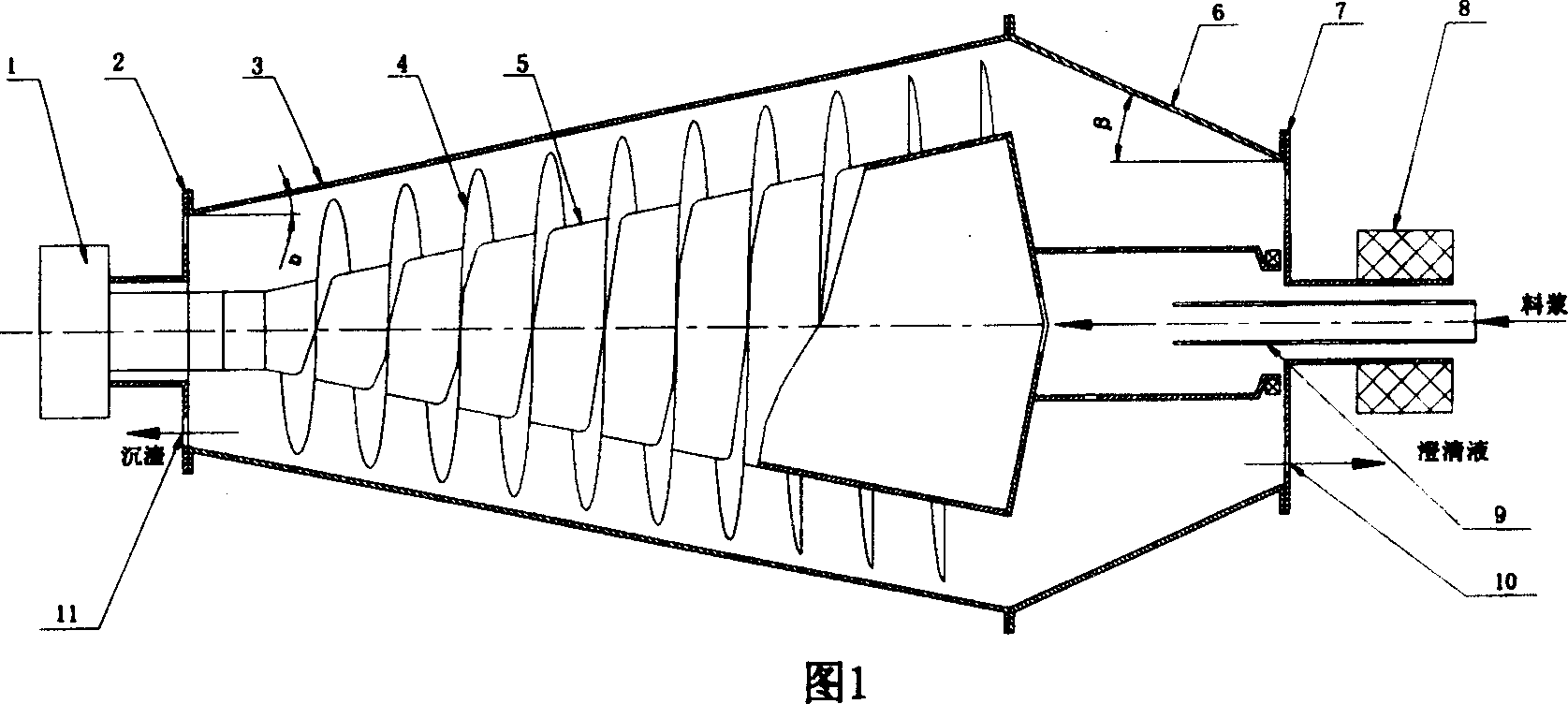

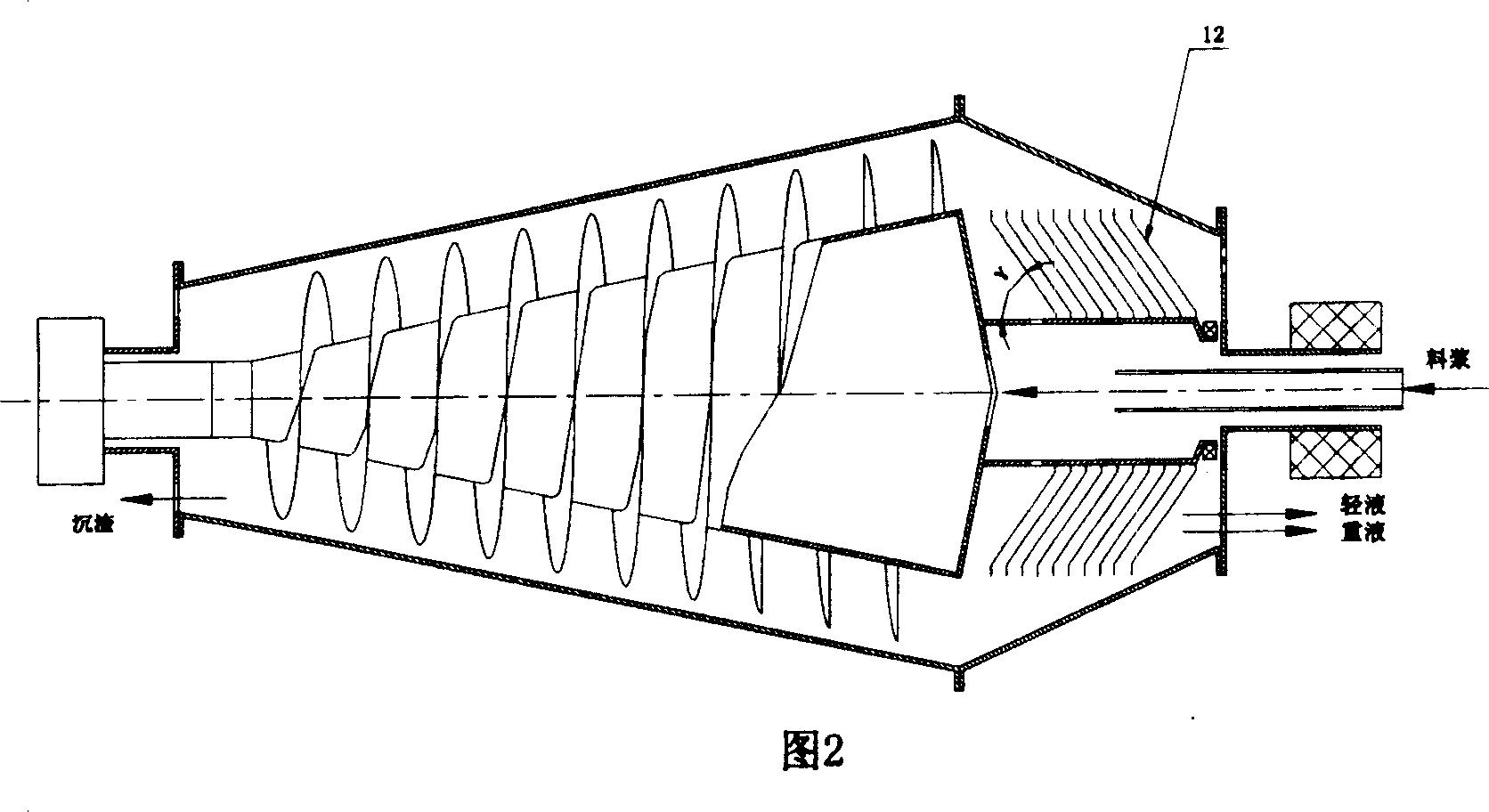

Horizontal spiral automatic discharge type sedimentation centrifuge with thorough separation effect

InactiveCN106964497AShorten the settlement distanceInhibitionRotary centrifugesEngineeringCentrifuge

The invention discloses a completely separated horizontal spiral automatic unloading sedimentation centrifuge. The drum is provided with a liquid inlet and a liquid outlet. Arranged in the same direction, the screw pusher mechanism is provided with discs arranged perpendicular to the axial direction near the liquid outlet, and multiple discs are arranged in layers. The horizontal spiral automatic unloading decanter centrifuge with thorough separation through the above optimization design has a reasonable structural design. By setting a multi-layer disc structure at the liquid outlet, the separated liquid phase hits the disc, shortening the solid The sedimentation distance of phase particles increases the sedimentation area, realizes the secondary solid-liquid separation, and at the same time suppresses the gas bubbles generated by high-speed rotation, so that the separated liquid phase is clearer and the separation effect is greatly improved.

Owner:ANHUI PUYUAN SEPARATION MACHINERY MFG CO LTD

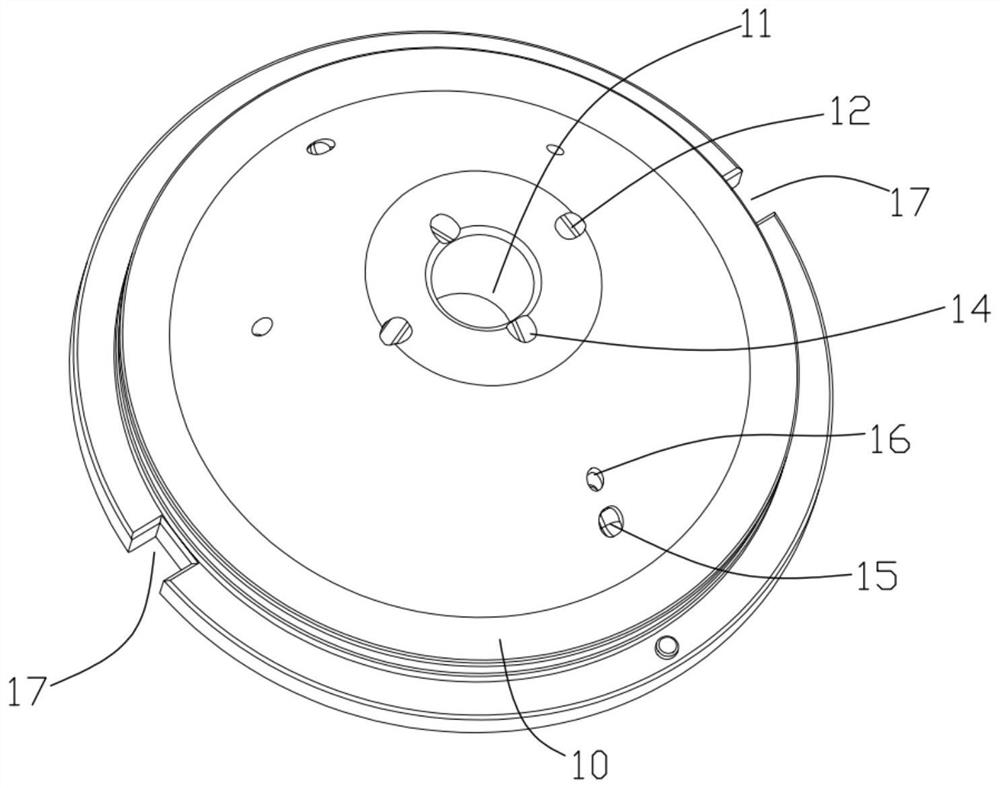

Anti-blockage disk system

The invention discloses an anti-blockage disk system. The anti-blockage disk system comprises multiple disks which are overlaid, a separation channel is arranged between the adjacent disks, part or one half of disks are open disks, other disks are conventional disks, openings are formed in the open disks, neutral holes are formed in the conventional disks, the neutral holes of the conventional disks correspond to the openings of the open disks, at least one open disk is arranged between two adjacent conventional disks, and an open channel is formed between the conventional disks and the openings o the open disks. The open channel is wider, when short fibers and large-particle impurities are contained in materials treated by a centrifugal machine, the short fibers and large-particle impurities can more smoothly move towards the open channel, blockage is not prone to happening, the deposition speed of a slag phase is improved, the sedimentation height is reduced, and the sedimentation area is increased; due to improvement of the disks, the device cleaning time is greatly prolonged, meanwhile, the influence of blockage impurities on the balance precision of a rotating drum is prevented, and due to the stable high-speed rotation, the service life of the system can be obviously prolonged.

Owner:JIANGSU JUNENG MASCH CO LTD +1

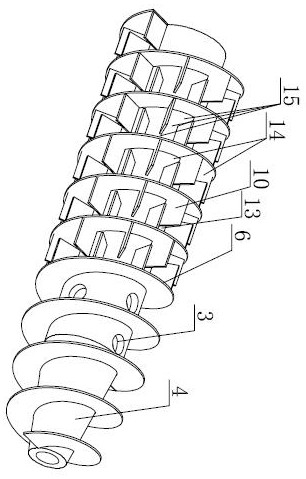

Disc stack centrifuge provided with single centripetal pump with spiral acceleration function and centrifugal equipment

PendingCN113245072AExtended separation timeImprove separation efficiencyRotary centrifugesEngineeringScrew thread

The invention provides a disc stack centrifuge provided with a single centripetal pump with a spiral acceleration function and disc stack centrifugal equipment provided with the single centripetal pump. The disc stack centrifuge is characterized in that a liquid inlet and outlet cover body is used for introducing mixed liquid and discharging light liquid; a spiral guide mechanism is arranged at the lower part of the liquid inlet and outlet cover body; the spiral guide mechanism comprises a fixing cover, a hollow column is arranged in the center of the fixing cover, a mixed liquid inlet pipe is inserted into the hollow column, at least two sets of openings are formed in the side wall of the end of the hollow column, and threaded grooves are formed in the positions, corresponding to the openings, of the outer wall of the hollow column; and the bottom of the hollow column is communicated with a guide disc. In the internal flow channel structure of the disc stack centrifuge, after entering the liquid inlet channel, mixed liquid is immediately accelerated by a screw pump in the hollow column to be pushed into a bottom liquid inlet channel and is immediately accelerated to the same rotating speed of the centrifuge, the separation effect is accelerated, and the defect that liquid entering a rotary drum cannot be completely accelerated to the rotating speed of the centrifuge through a traditional centrifuge with a single centripetal pump is overcome.

Owner:昆山金牛动力机械有限公司

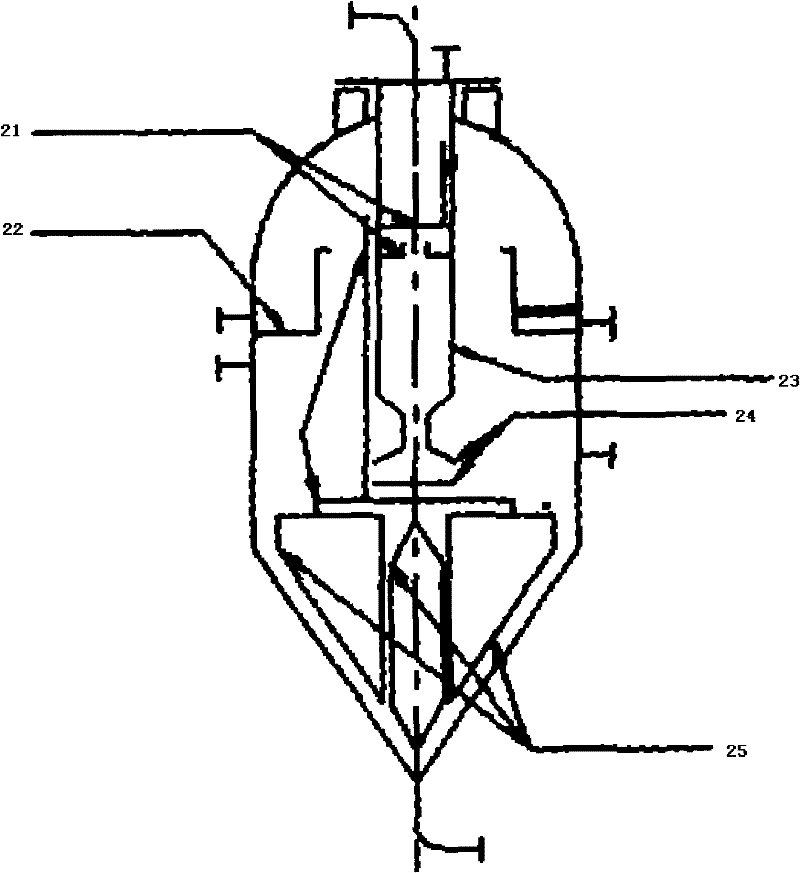

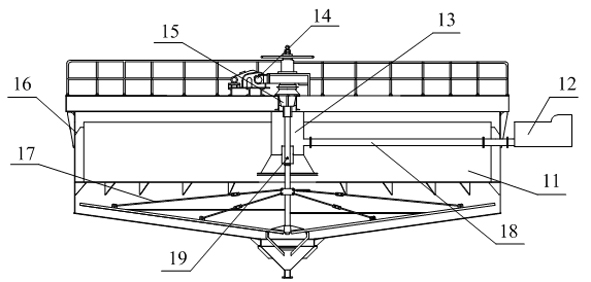

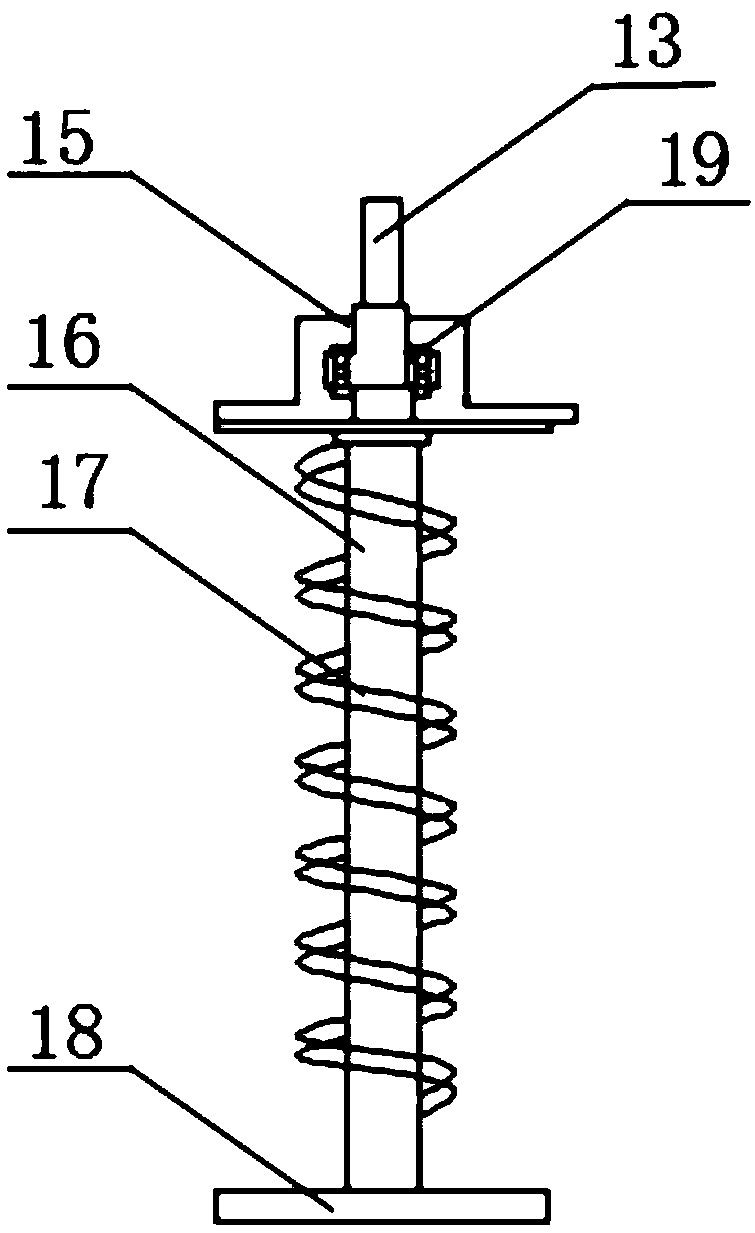

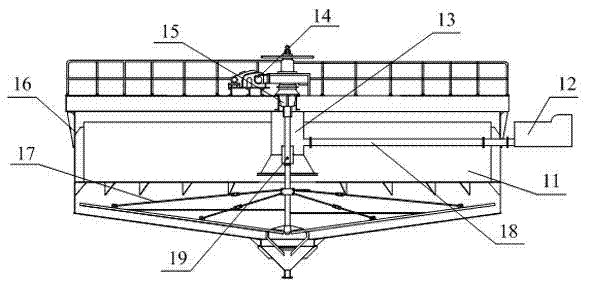

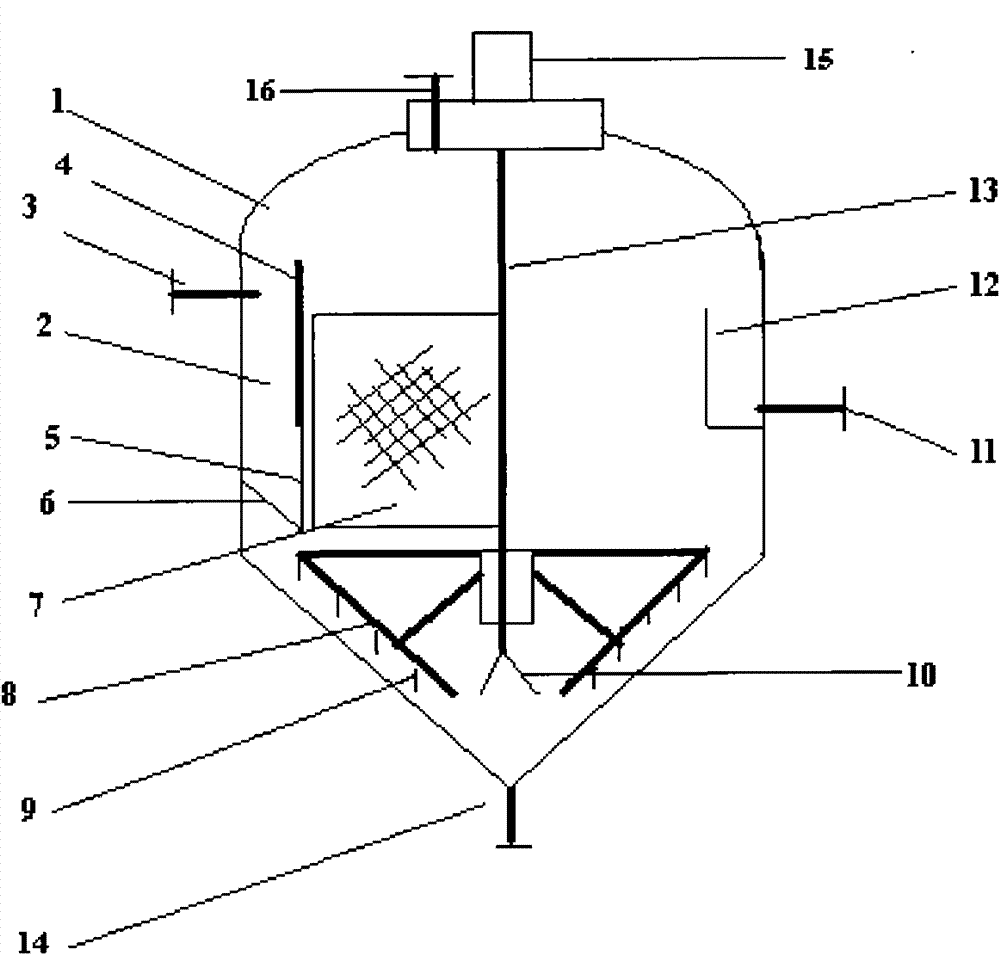

Novel slow-flow efficient thickener

ActiveCN101961566AEasy to handleLow stream turbiditySettling tanks feed/dischargeSedimentation settling tanksAgricultural engineeringTurbidity

The invention relates to a novel slow-flow efficient thickener. The novel slow-flow efficient thickener comprises a tank body, a degassing tank, a central feed blending barrel, a motor transmission device, a rake rack lifting device, a slow-flow device, an overflow weir, a rake rack, a feeding device and a vertical shaft; the vertical shaft is arranged in the middle of the tank body; the verticalshaft passes through the central feed blending barrel, the rake rack is fixed at one end of the vertical shaft, and the other end of the vertical shaft is connected with the rake rack lifting device;the rake rack lifting device is connected with the motor transmission device, and a scraper is connected on the rake rack; the degassing tank is connected with the feeding device, and the feeding device is connected with the central feed blending barrel; and the central feed blending barrel is connected with the slow-flow device, and the slow-flow device is connected with the overflow weir. Compared with the traditional thickener, the novel slow-flow efficient thickener has high processing capability and low flow turbidity, and improves the discharging concentration.

Owner:烟台鑫海矿业研究设计有限公司

Liquid-liquid extraction mixer-settler and extraction method and application thereof

InactiveCN103120863BSimple structureCompact structureLiquid solutions solvent extractionSingle stagePhase splitting

The invention relates to a liquid-liquid extraction mixer-settler and an extraction method and an application thereof. The mixer-settler comprises a mixing chamber and a clarifying chamber, wherein the side in the clarifying chamber near the mixing chamber is provided with a guide pipe which extends to the tail end of the clarifying chamber from an outlet of the mixing chamber; and at least the upper part or the lower part of the guide pipe in the clarifying chamber is transversely and fixedly provided with a wedge-shaped body. As the upper part and / or the lower part of the guide pipe in the clarifying chamber is fixedly provided with the wedge-shaped body, not only is the storage amount of organic phases in the settling chamber reduced, but also a large light-heavy two-phase settling area is provided so that the clarifying phase-splitting time is prolonged, and the clarifying separation effect is remarkable for an easily-emulsifying system or a system with larger viscosity; and the mixer-settler provided by the invention can be used for single-stage continuous extraction operation or multi-stage series-connected countercurrent continuous extraction operation.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

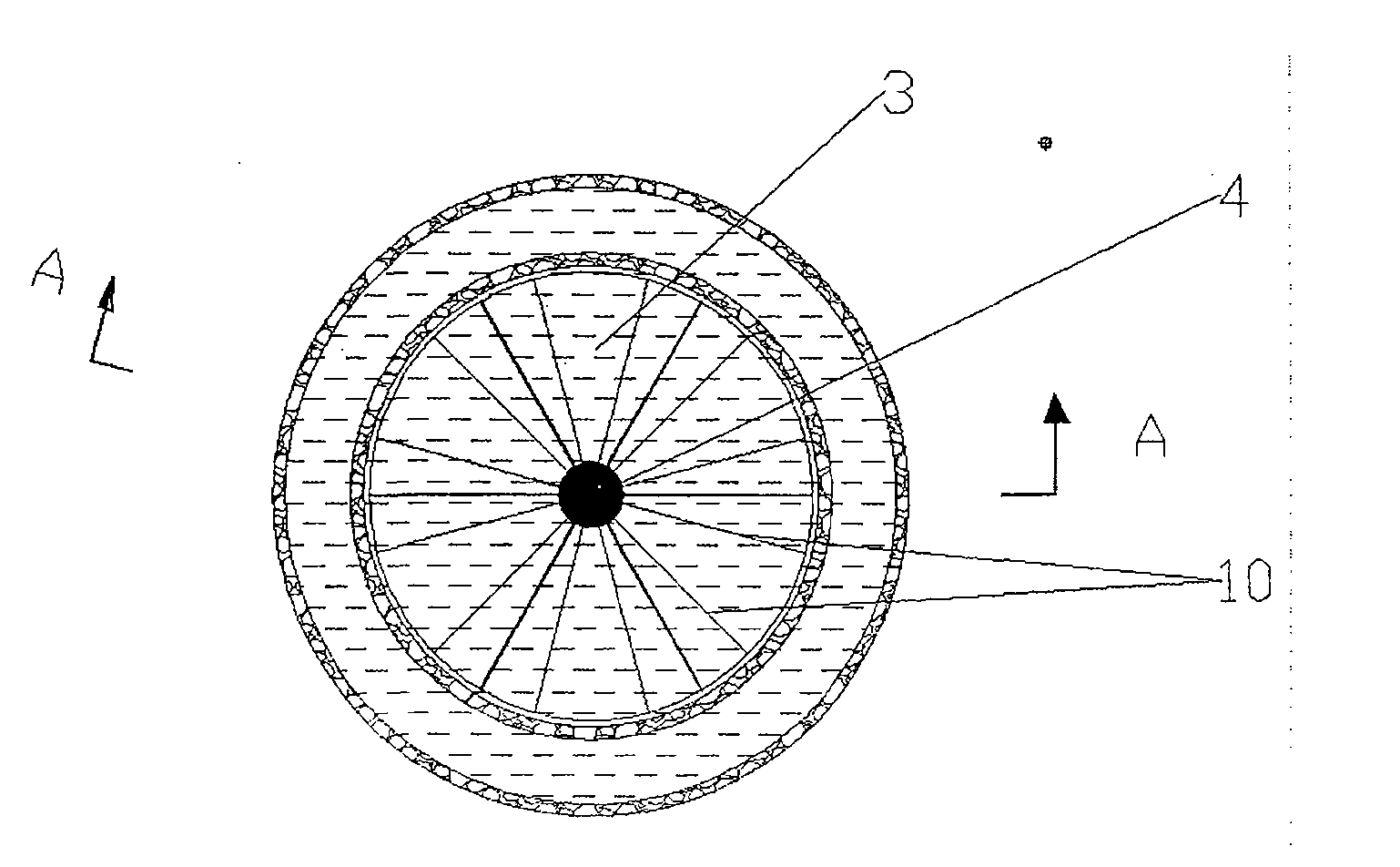

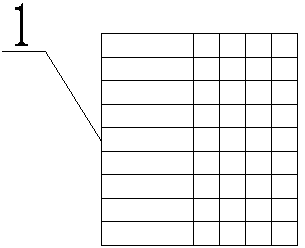

Radial settling tank with multiple layer settlement plate

InactiveCN100571837CImprove volume utilizationIncrease the settlement areaSedimentation settling tanksSludgeAgricultural engineering

The invention discloses a radial flow sedimentation tank with multi-layer settling plates, which belongs to the technical field of agricultural engineering. The technical solution includes the main body of the settling tank, the sump and clear water pipe arranged on the upper part of the main body of the settling tank, the water inlet pipe arranged at the lower part of the main body of the settling tank, the water distribution cylinder with water outlet holes, the mud discharge bucket, the sludge pipe, etc., and is characterized in that In the main body of the settling tank, multiple layers of settling plates are set up and down. Each layer of settling plates is a round or edge table with an angle with the horizontal plane, that is, each layer of settling plates is a slope with a high outer edge and a low center. The present invention introduces multi-layer settling plates into the settling tank, which increases the settling area per unit volume and improves the volume utilization rate of the settling tank; the settling plate can prevent the short flow that is easy to form in the general radial flow settling tank; without moving parts, it improves settling conditions. It reduces the occupied area, reduces the infrastructure cost, and the operation and maintenance cost is low.

Owner:CHINA AGRI UNIV

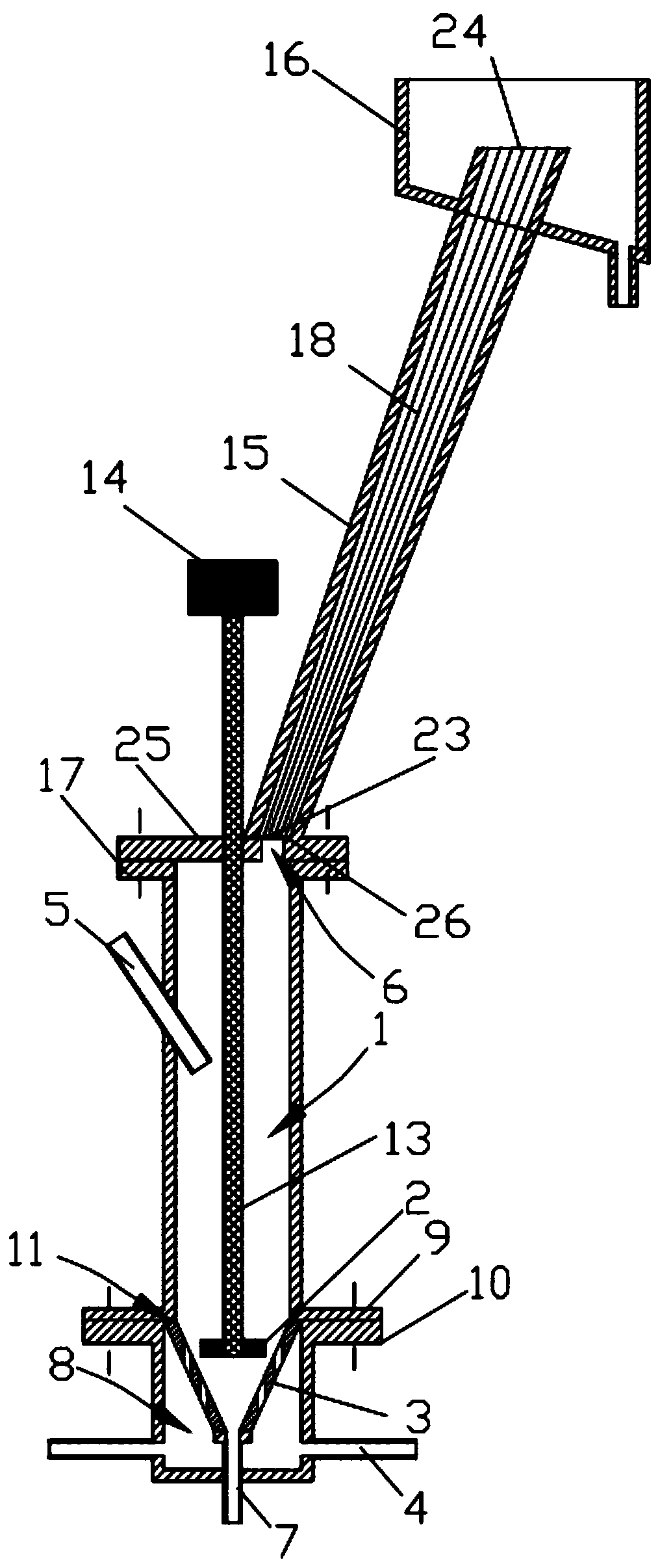

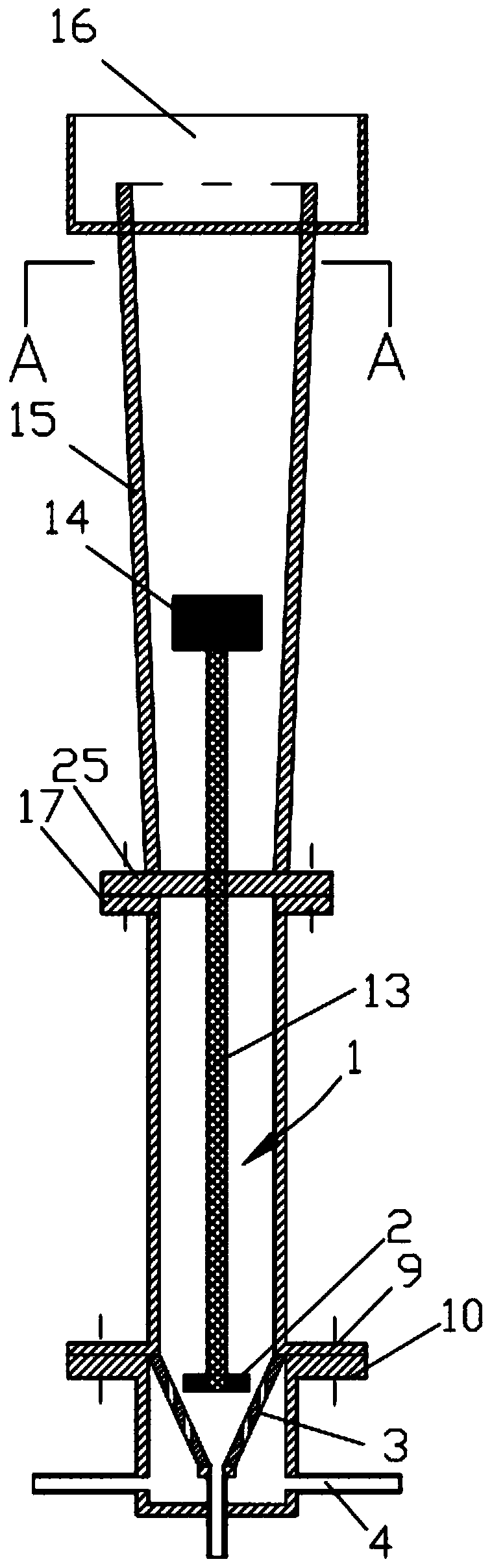

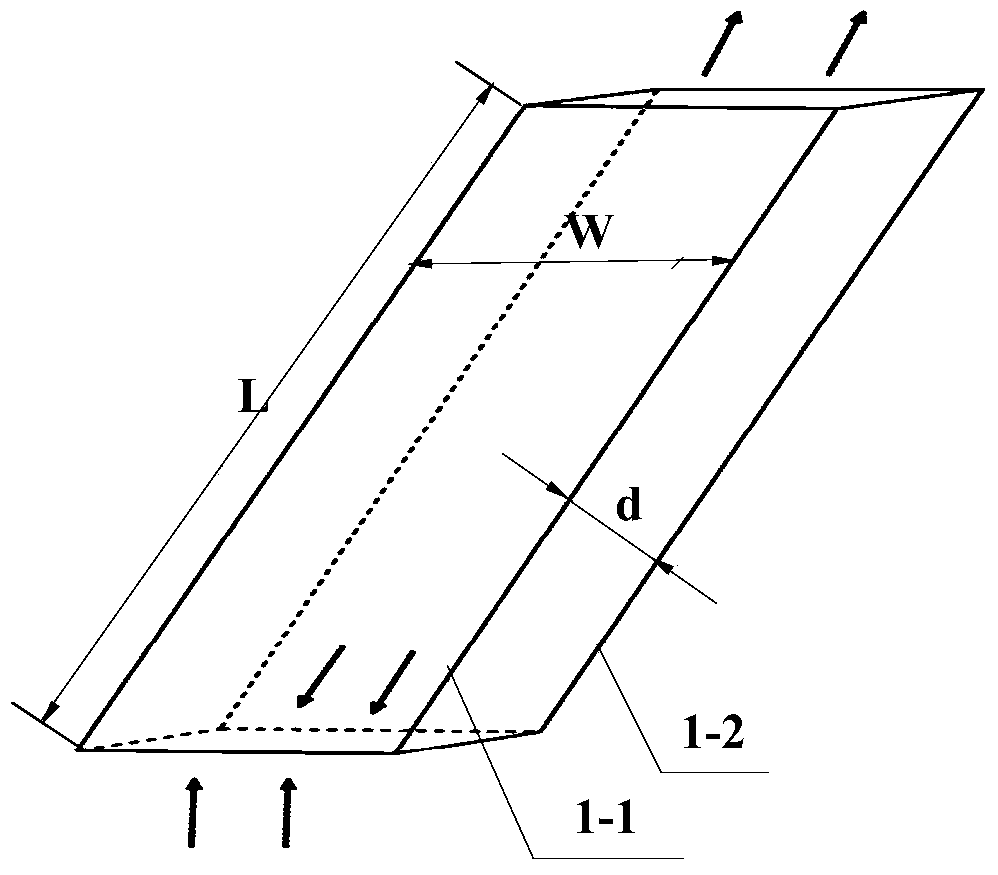

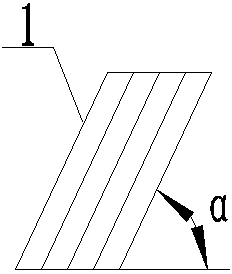

Special-shaped inclined plane countercurrent sorting device

PendingCN111468283AIncrease the settlement areaReduce disturbanceWet separationMechanical engineeringMechanics

The invention discloses a special-shaped inclined plane countercurrent sorting device. The special-shaped inclined plane countercurrent sorting device comprises a sorting chamber, a stirring impellerand a water distribution piece, wherein the stirring impeller and the water distribution piece are arranged in the sorting chamber; a water inlet is formed in the bottom of the sorting chamber; a feeding hole is formed in the upper part of the sorting chamber; an upward floating particle outlet is formed above the feeding hole; an opening in the upper end of the water distribution piece faces thestirring impeller, and the lower end of the water distribution piece communicates with a bottom flow hole of the sorting chamber; water distribution holes are formed in the water distribution piece; aspecial-shaped inclined plane sorting column is obliquely arranged at the upward floating particle outlet; an overflow groove is formed in an output hole of the special-shaped inclined plane sortingcolumn; a plurality of layers of inclined plates which are obliquely arranged along the axis of the special-shaped inclined plane sorting column are arranged in the special-shaped inclined plane sorting column; and the inner diameter of the special-shaped inclined plane sorting column is gradually increased from the upward floating particle outlet to the overflow groove. According to the special-shaped inclined plane countercurrent sorting device, the flowing speeds of fluids at different heights can be changed, so that the sorting precision and efficiency are improved.

Owner:CENT SOUTH UNIV

Wastewater treatment method for wet regeneration of mixed casting waste sand

ActiveCN103351065BSolve the disadvantages of being difficult to effectively dehydrateGuaranteed uptimeMultistage water/sewage treatmentWater useFlocculation

The invention provides a wastewater treatment method for wet regeneration of mixed casting waste sand. First, the wastewater is demulsified, and then the suspended matter with larger particles in the wastewater is flocculated in a spiral flocculation tank with an inorganic flocculant, and then an organic flocculant is used to The flocculant flocculates the suspended solids with small particles, and passes through the inclined tube settling tank for static settlement. The floc layer formed by compression at the bottom is pumped out by the sludge pump at the bottom of the settling tank, flocculated with organic flocculant again, and finally concentrated by belt type vacuum filter Integrated machine treatment, the moisture content of the sludge coming out of the filter cake outlet of the belt-type concentrated vacuum filter press integrated machine is below 40%; while the overflow supernatant of the inclined tube settling tank and the clear water outlet The clean water meets the requirements of production circulation water and the standard of direct discharge.

Owner:广西兰科资源再生利用有限公司

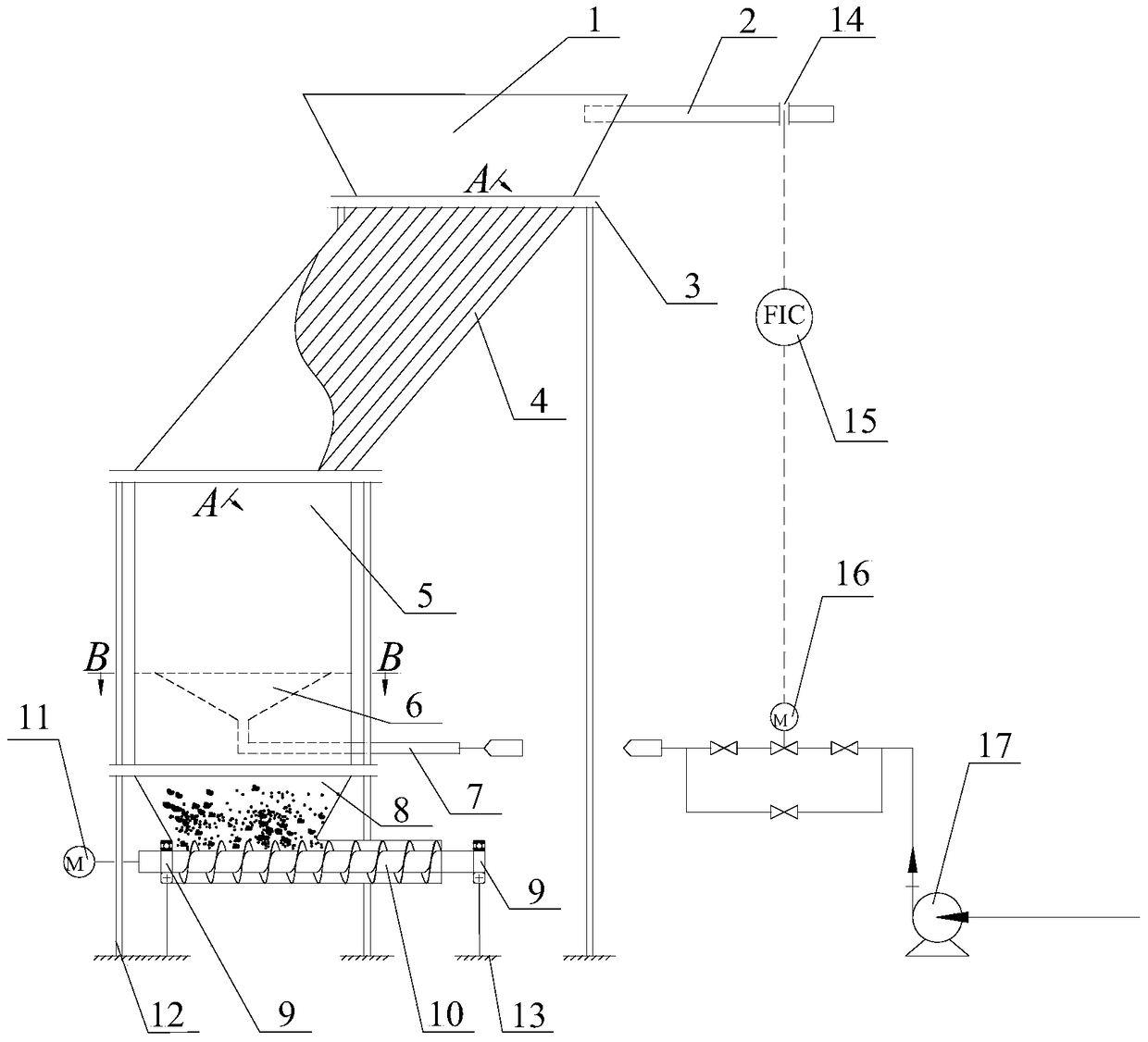

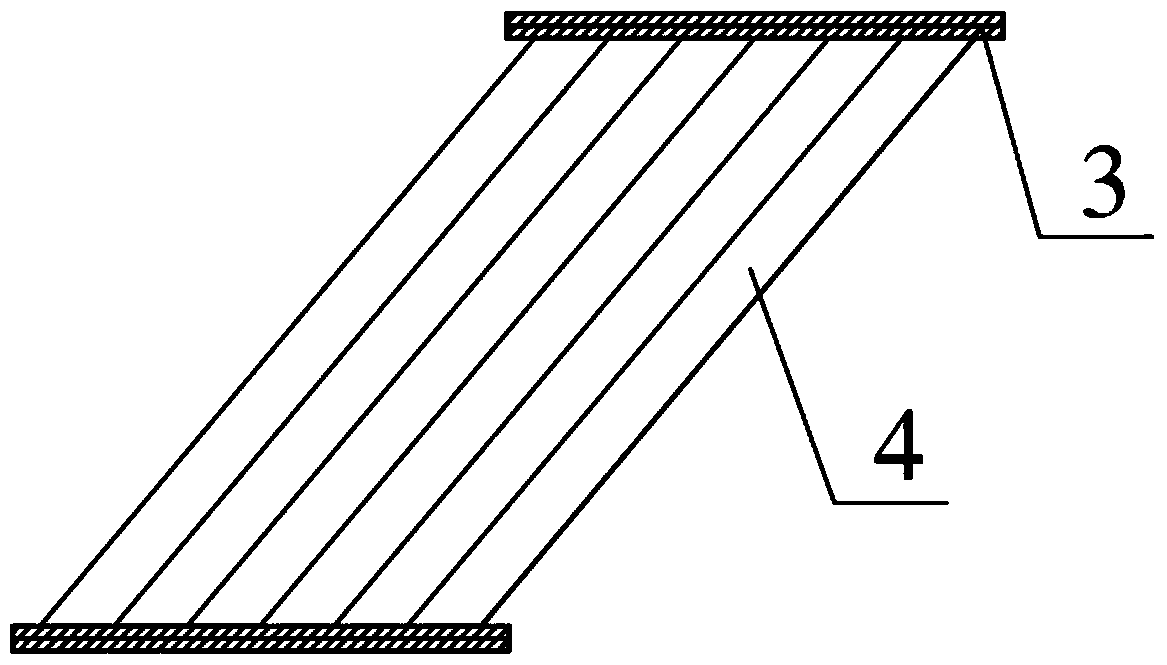

Efficient flocculation thickener

InactiveCN108635917AGuarantee the unimpeded dischargeAvoid cloggingSettling tanks feed/dischargeSedimentation settling tanksEngineeringPrecipitation

The invention discloses an efficient flocculation thickener. The efficient flocculation thickener comprises a shell body and bridge piers, wherein the shell body is arranged on two adjacent groups ofthe bridge piers; a bridge frame is arranged at the upper end of the shell body; a main shaft is arranged at the middle position in the shell body; a driving device is arranged at the upper end of themain shaft; a flow stabilization barrel is arranged at a part, close to the top end, of the outer surface of the main shaft; a supporting barrel is arranged on the outer surface of the flow stabilization barrel; the flow stabilization barrel and the supporting barrel are coaxially arranged through the main shaft; overflowing holes are formed in positions above two sides of the shell body; a shortrake is arranged at a part, close to the bottom end, of one side of the main shaft; a long rake is arranged at the bottom end of the other side, corresponding to the short rake, of the main shaft. The efficient flocculation thickener disclosed by the invention is provided with a material push plate and an inclined flow plate, so that the discharging smoothness of slurry in the device is ensured,a precipitation distance of ore grains is shortened, the precipitation area is enlarged and a better application prospect is brought.

Owner:石城县华辉选矿设备制造有限公司

Spiral conveyor with auxiliary blades and spiral discharging sedimentation centrifuge

PendingCN112827665APromote separationImprove separation efficiencyRotary centrifugesFluid phaseMechanics

The invention discloses a spiral conveyor with auxiliary blades. A hollow inner barrel is provided with a conical section and a straight barrel section, a feeding hole is formed in the pipe wall close to the conical section, spiral blades are arranged at the periphery of the inner barrel, the plurality of auxiliary blades are arranged between the spiral blades, the width of the auxiliary blades is smaller than the pitch of the spiral blades, and every two adjacent auxiliary blades are arranged in a spiral channel space in a staggered manner to form a zigzag flow channel. The auxiliary blades are additionally arranged between the spiral blades and rotate along with the inner barrel, solid particles of suspension liquid entering the spiral conveyor are separated from a liquid phase under the action of a huge centrifugal force field, and the manner that the liquid is driven to rotate only through the spiral blades originally is changed through the auxiliary blades. The auxiliary blades drive the suspension liquid entering the space between the inner barrel and an outer barrel from discharging holes, so that the centrifugal force and the rotating speed can be immediately obtained, the solid-liquid two-phase separation is accelerated, and the separation efficiency is improved. Meanwhile, the auxiliary blades also increase the equivalent sedimentation area, so that a better separation effect is achieved.

Owner:JUNENG MACHINERY CHINA

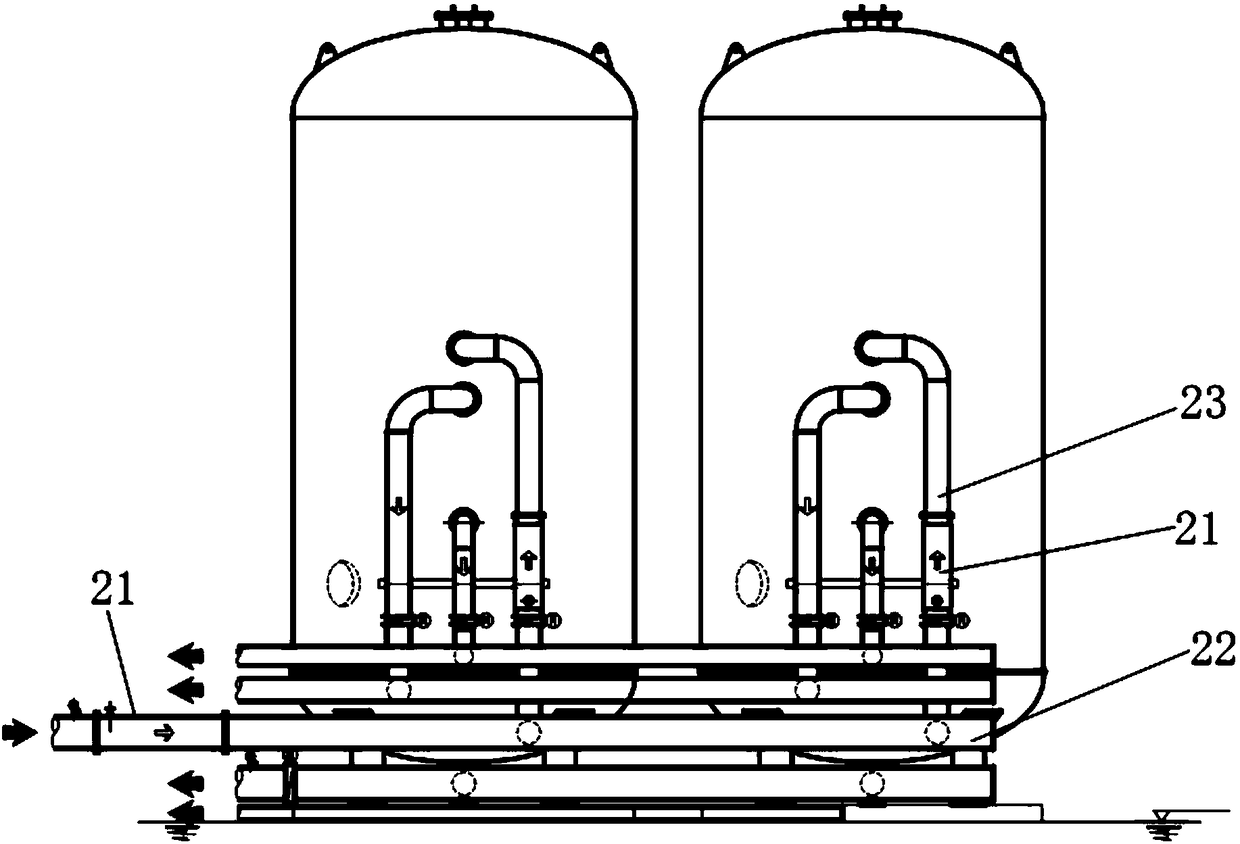

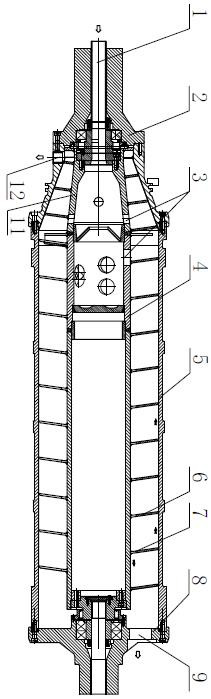

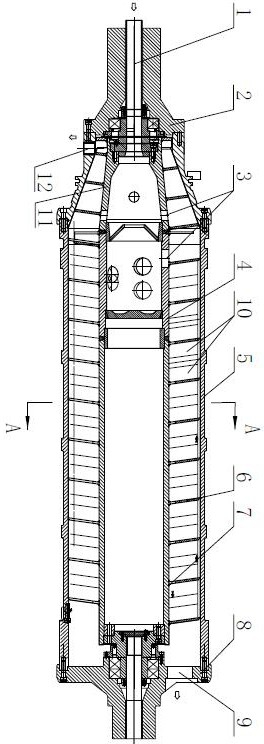

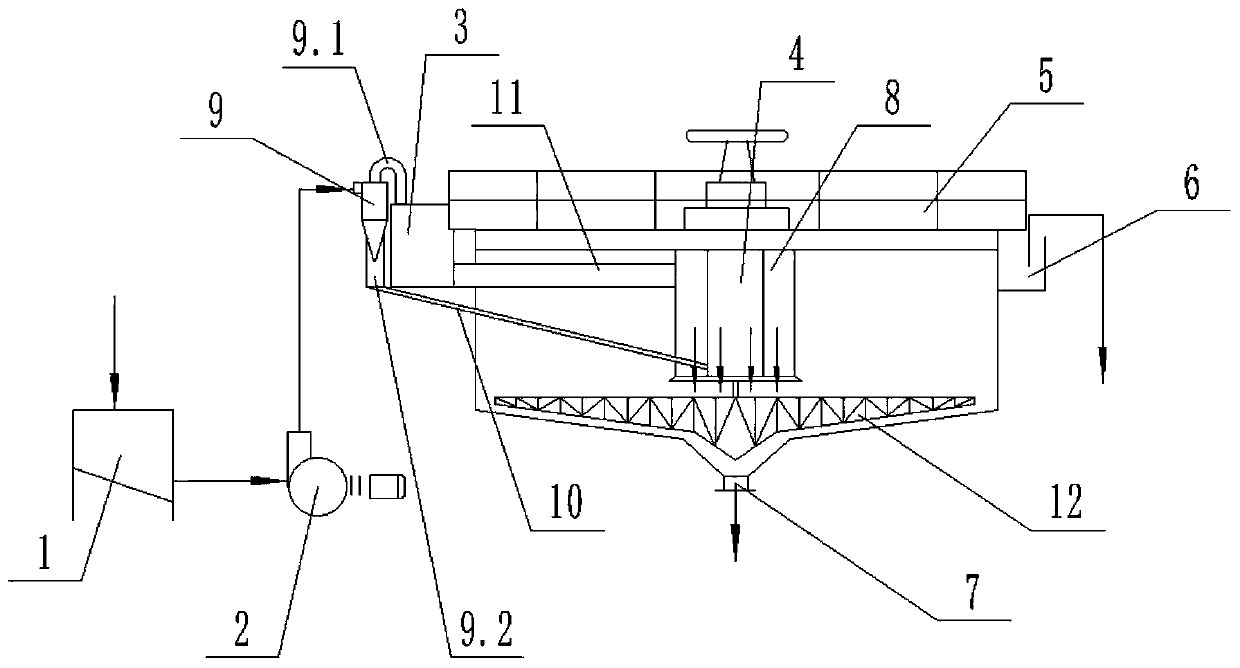

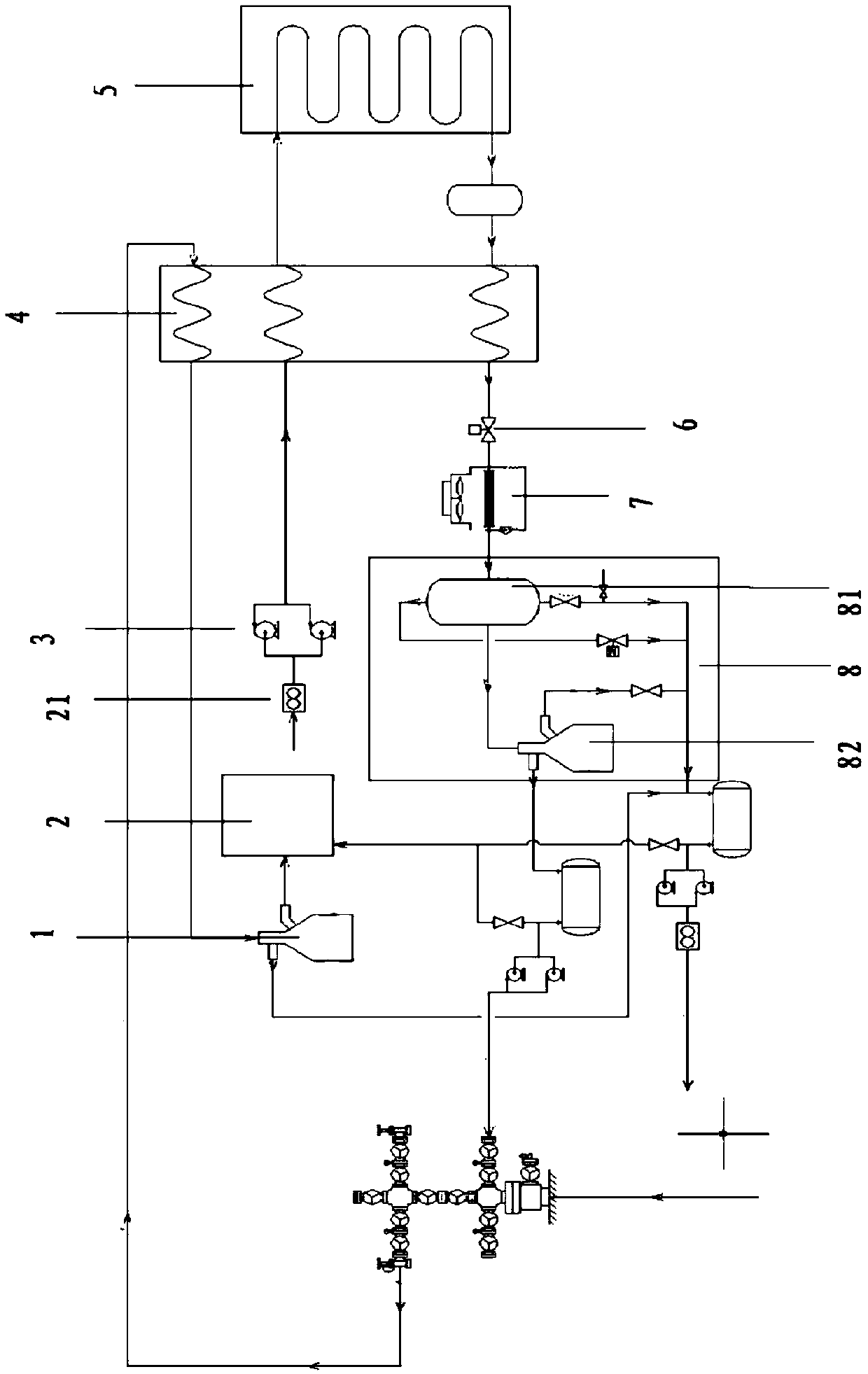

System and method for improving thickener handling capacity

ActiveCN110732165AIncrease the settlement areaIncrease throughputCentrifugal force sediment separationProcess efficiency improvementThermodynamicsProcess engineering

The invention relates to a system for improving thickener handling capacity. The system is characterized by comprising a slurry pump, a cyclone, and a thickener; a central feeding cylinder is arrangedat the upper part in the thickener; an outer feeding cylinder is arranged outside the central feeding cylinder; a feeding pipe of the cyclone is connected with the slurry pump; an overflow pipe of the cyclone is connected with a feeding port of a degassing tank, and a feeding port of the degassing tank is connected with the upper portion of the outer wall of the outer feeding cylinder through a low-concentration feeding pipe; an underflow pipe of the cyclone is connected with the bottom of the outer wall of the central feeding cylinder through a high-concentration feeding pipe. The inventionfurther relates to a method for improving thickener handling capacity. by utilizing the system. The system is simple in design and economical in cost; ore pulp is divided into low-concentration fine particles and high-concentration coarse particles for settling and reasonable flow separation; the handling capacity of the thickener is increased without changing the appearance of the thickener, theuse amount of a flocculating agent is reduced, meanwhile, the underflow concentration of the thickener is increased, and a promising application prospect is achieved.

Owner:烟台鑫矿服工程管理集团有限公司

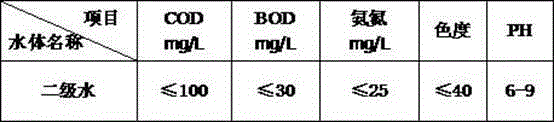

Novel domestic sewage treatment method

InactiveCN107758981AEasy to handleEfficient removalTreatment using aerobic processesWater/sewage treatment by irradiationActivated sludgeBacterial virus

The invention relates to a novel domestic sewage treatment method. The treatment method mainly aims at excrement sewage of a toilet. The mode combining activated sludge biodegradation, inclined tube sedimentation and physical disinfection and sterilization is used. The method mainly comprises the four steps of anaerobic treatment, aerobic treatment, sedimentation treatment and disinfection treatment in sequence. The method can effectively remove nutrient substances such as nitrogen and phosphorus in domestic sewage and remove bacterial viruses such as escherichia coli, and is clean, sanitary,free of peculiar smell and capable of efficiently treating sewage. The quality of the treated water can reach the secondary emission standard of municipal sewage treatment plant pollutant emission standards. The treated water can be used for toilet flushing; in addition, reclaimed water can be recycled, circulating water flushing can be achieved, and water resources are greatly saved.

Owner:LIAONING PETROLEUM EQUIP INST +1

A kind of wet method continuous grading equipment and grading method for flaky particles

ActiveCN105344460BSimple production processReduce entrainmentWet separationClosed loopConical cavity

The invention discloses a wet process continuous classifying device and method for flaky grains. The wet process continuous classifying device comprises a bottom end material accumulating section, a fluidization section, an inclined ascending flow section, a reducing ascending flow section and a closed-loop flow constant value feedback control system. A liquid-solid fluidized bed of the fluidization section is a sealed cavity, and a fluid distributor is arranged at the bottom in the cavity. The bottom of the fluid distributor is connected with a feeding pipe. The fluid distributor is composed of a distribution plate and a conical cavity. A gap of 10-100 mm exists between the distribution plate and the inner surface of a box of the fluidization section. During classifying, prepared suspension liquid is conveyed through a centrifugal pump to flow through the fluid distributor to enter the fluidization section, the grains are sequentially classified through the fluidization section, the inclined ascending flow section and the reducing ascending flow section, small grain suspension fluid overflows from a top end overflow pipe, and after a material seal is formed by large grains on the equipment material accumulating section, the large grains are output from a screw discharger. The wet process continuous classifying device and method have the beneficial effects that operation is stable, continuous production is achieved, the automation degree is high, the processing amount is large per unit occupied area, the product grain fineness distribution is narrow, and the production cost is low.

Owner:广东三宝新材料科技股份有限公司 +1

Clear liquid disturbanceless spiral discharging settling centrifugal machine

InactiveCN1302854CEasy to separateIncrease the settlement areaRotary centrifugesSpiral bladeAgricultural engineering

A centrifugal machine for clarifying liquid technically features that its drum-type overflow segment of clarified liquid has a hollow conic structure, the part of spiral conveyer, which is relative to said overflow segment, has no spiral blade, and the dregs are centrifugally pushed toward the dregs discharge segment and then are delivered to dregs outlet by spiral blades.

Owner:SICHUAN UNIV

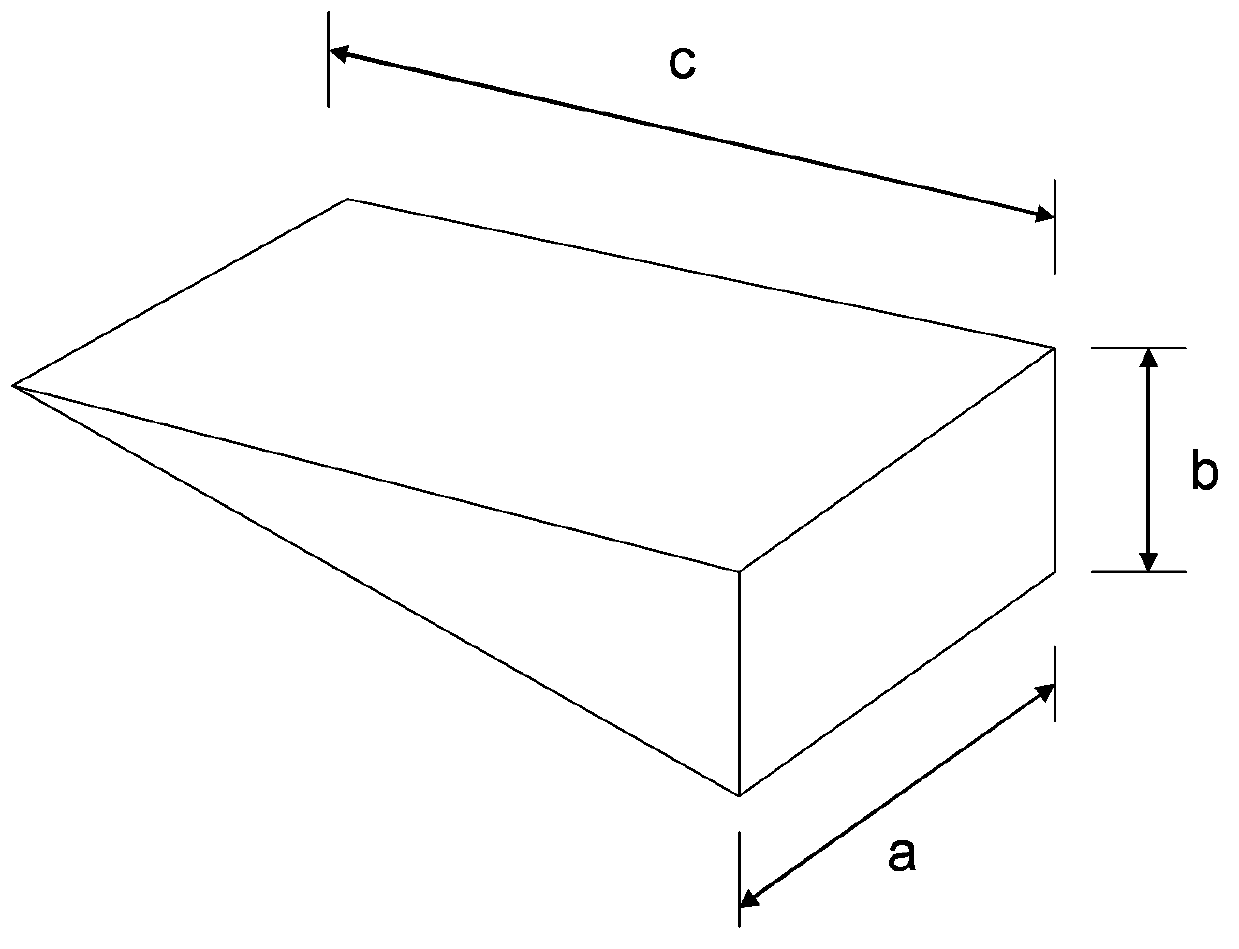

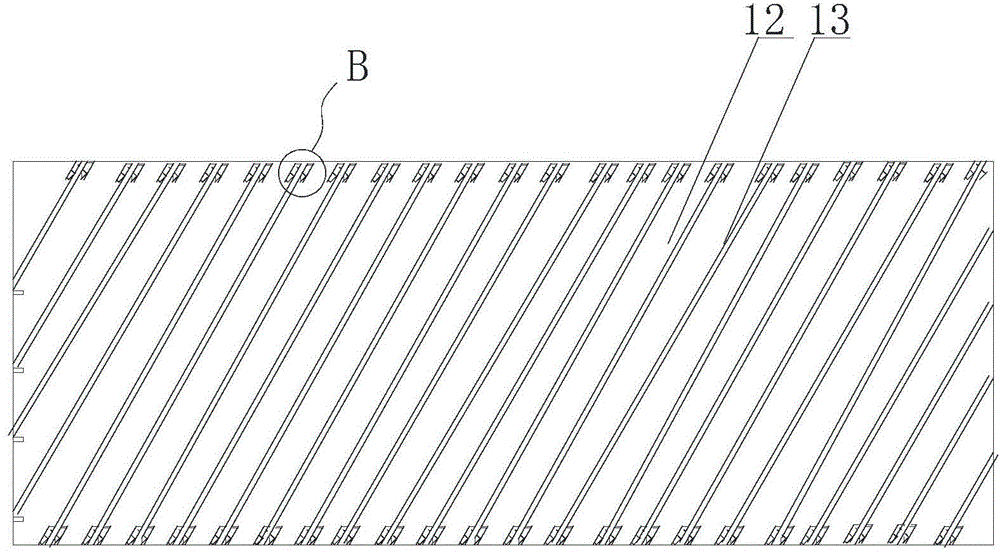

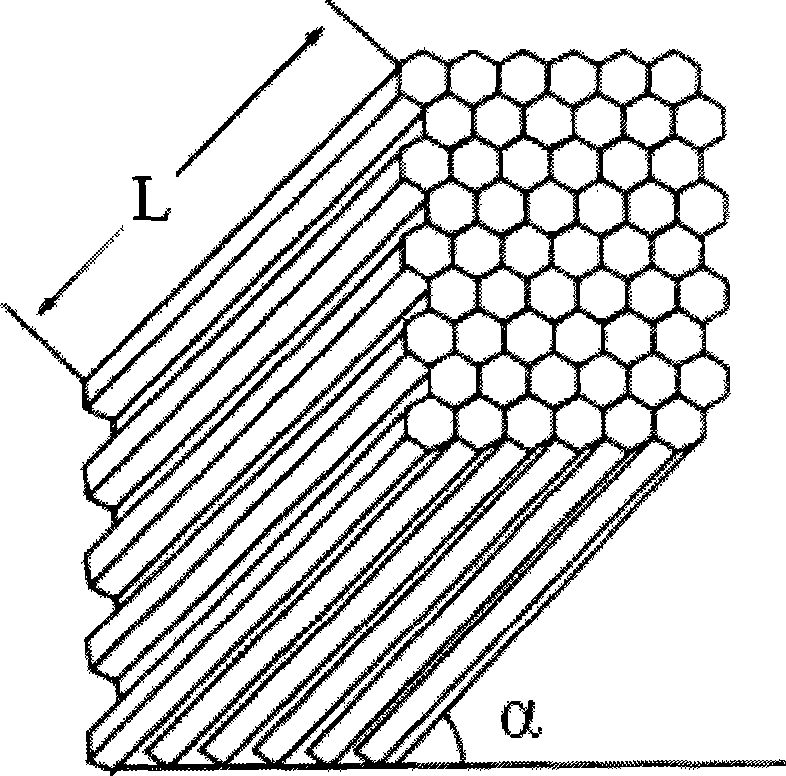

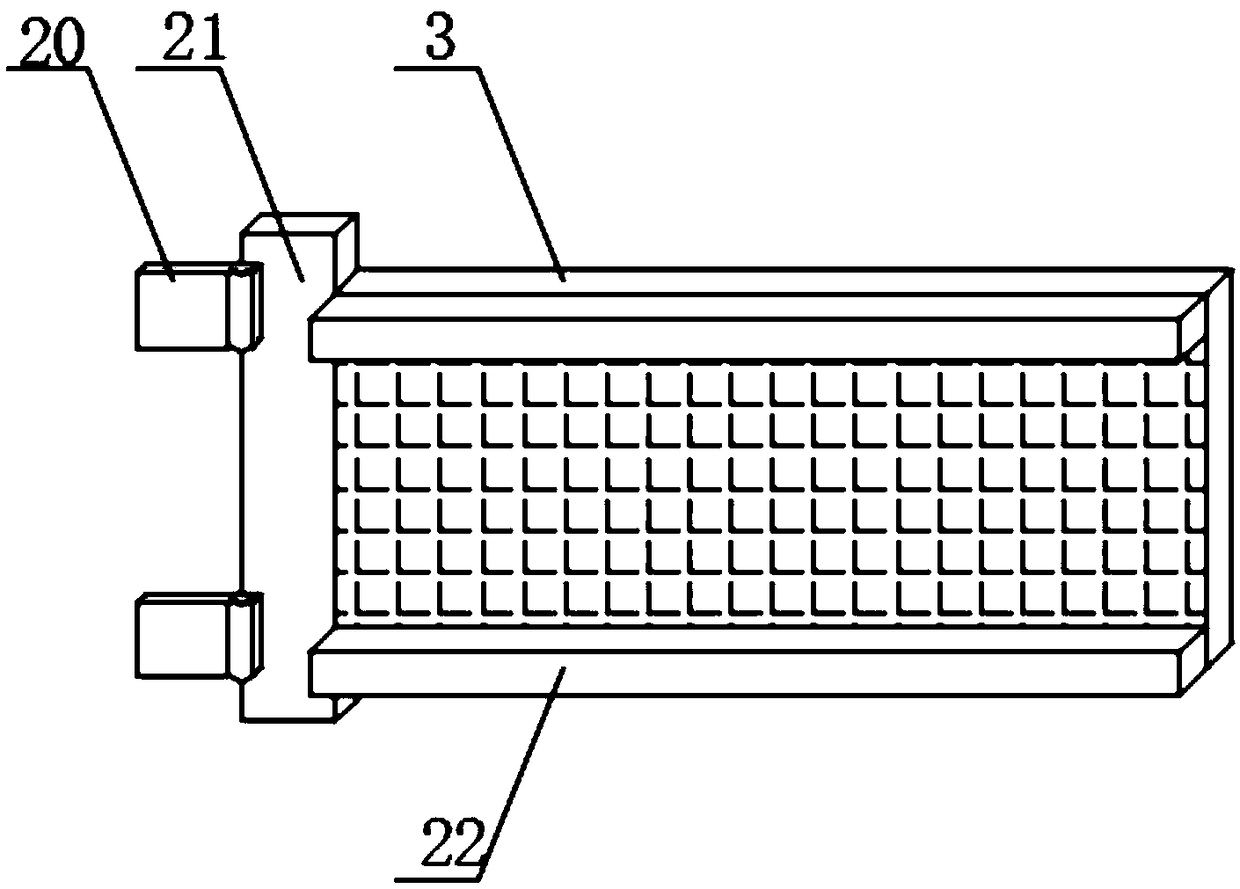

Arrangement structure and method of inclined tube bodies in inclined tube thickener

The invention relates to arrangement structure and method of inclined tube bodies in an inclined tube thickener. The inclined tube bodies are oblique cuboids, and are linearly and tightly arranged ina thickening tank of an inclined tube thickener in multiple lines; after the inclined tube bodies are arranged in the thickening tank of the inclined tube thickener, a plurality of arc-shaped vacant sites are formed between the inclined tube bodies and the wall of the thickening tank; and the arc-shaped vacant sites are respectively filled with shaped inclined tube bodies. The arrangement method of the inclined tube bodies is as follows: by taking any diameter in the thickening tank of the round inclined tube thickener as a datum line, arranging a middle row of inclined tube bodies; arrangingsymmetric rows at two sides close to the middle row at two sides of the middle row, wherein the start point of the symmetric rows is close to the inner wall of the thickening tank of the round inclined tube thickener, and the inclined tube bodies are arranged forwards in sequence, until reaching the opposite wall of the thickening tank; sequentially arranging symmetric rows outside the arranged symmetric rows at two sides, and so on, until the whole thickening tank is filled up with the inclined tube bodies. The inclined tube bodies are tightly and orderly arranged, the arrangement method is simple and convenient, arrangement is tight, appearance is ordered, material is saved, and construction is easy.

Owner:TANGSHAN SENPU MINING EQUIP CO LTD

Novel slow-flow efficient thickener

ActiveCN101961566BEasy to handleLow stream turbiditySettling tanks feed/dischargeSedimentation settling tanksAgricultural engineeringTurbidity

The invention relates to a novel slow-flow efficient thickener. The novel slow-flow efficient thickener comprises a tank body, a degassing tank, a central feed blending barrel, a motor transmission device, a rake rack lifting device, a slow-flow device, an overflow weir, a rake rack, a feeding device and a vertical shaft; the vertical shaft is arranged in the middle of the tank body; the verticalshaft passes through the central feed blending barrel, the rake rack is fixed at one end of the vertical shaft, and the other end of the vertical shaft is connected with the rake rack lifting device;the rake rack lifting device is connected with the motor transmission device, and a scraper is connected on the rake rack; the degassing tank is connected with the feeding device, and the feeding device is connected with the central feed blending barrel; and the central feed blending barrel is connected with the slow-flow device, and the slow-flow device is connected with the overflow weir. Compared with the traditional thickener, the novel slow-flow efficient thickener has high processing capability and low flow turbidity, and improves the discharging concentration.

Owner:烟台鑫海矿业研究设计有限公司

Channel type thickener

InactiveCN105327528ASimple structureSave spaceSedimentation settling tanksWater savingSettling basin

The invention provides a channel type thickener. The thickener comprises a thickening pool, a settling basin, a desilting valve and a mud cleaning valve; wherein an upper part of the thickening pool comprises a buffer pool, which is connected to the settling basin; one end of the desilting valve is communicated with a bottom part of the buffer pool, and the other end of the desilting valve is communicated with an outlet at a lower part of the thickening pool; one end of the mud cleaning valve is communicated with the front end of the bottom of the settling basin, and the other end is communicated with the outlet at the lower part of the thickening pool; liquid at the upper part of the settling basin is communicated with a drainage hole. The thickening pool, the buffer pool, the settling basin, the desilting valve and the mud cleaning valve are arranged linearly in order for condensation and treatment of tailings, and the separated clear water can be discharged or recycled for utilization on-site. The thickener has the advantages of simple structure and saved space, so that power saving and water saving are realized.

Owner:黄武

Continuous settling tank

InactiveCN102225251BEfficient use ofIncrease the settlement areaLiquid degasificationLiquid separationInterior spaceEngineering

The invention discloses a continuous settling tank which comprises a shell, wherein the shell is provided with a circular cylinder at the upper part and a conical cylinder at the lower part; an overflow weir is arranged in the circular cylinder; an underflow outlet is arranged at the bottom of the conical cylinder; an arch-shaped feeding slot is arranged in the circular cylinder of the shell; the arch-shaped feeding slot comprises the inner side wall of the circular cylinder, a flat wall plate, a grid distributing plate and a baseboard; the grid distributing plate is arranged under the flat wall plate; upper and lower ends of the grid distributing plate are respectively fixedly connected to the flat wall plate and the baseboard; a plurality of porous guiding vanes are symmetrically and obliquely arranged outside the flat wall plate; gaps are reserved between the guiding vanes and the flat wall plate; and a rotary rake is arranged on the conical cylinder at the lower part of the shell. By using the continuous settling tank provided by the invention, the maximum settling area is supplied as much as possible, an interior space of equipment is efficiently utilized, a settling separating effect is improved, and the loss of solid materials such as catalyst can be reduced.

Owner:TIANJIN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com