Canal type thickener

A thickener and channel-type technology, applied in the field of thickeners, can solve the problems of restricting the application of small and medium-sized mineral processing enterprises, large area and high cost, saving materials, solving the effect of large area and long channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

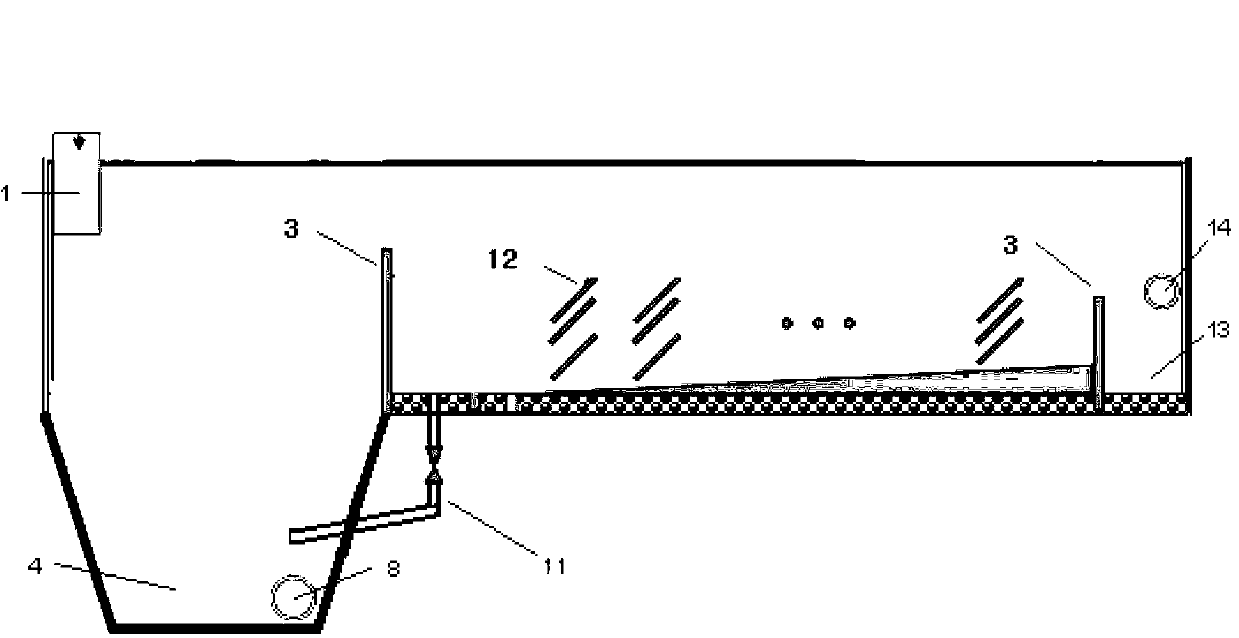

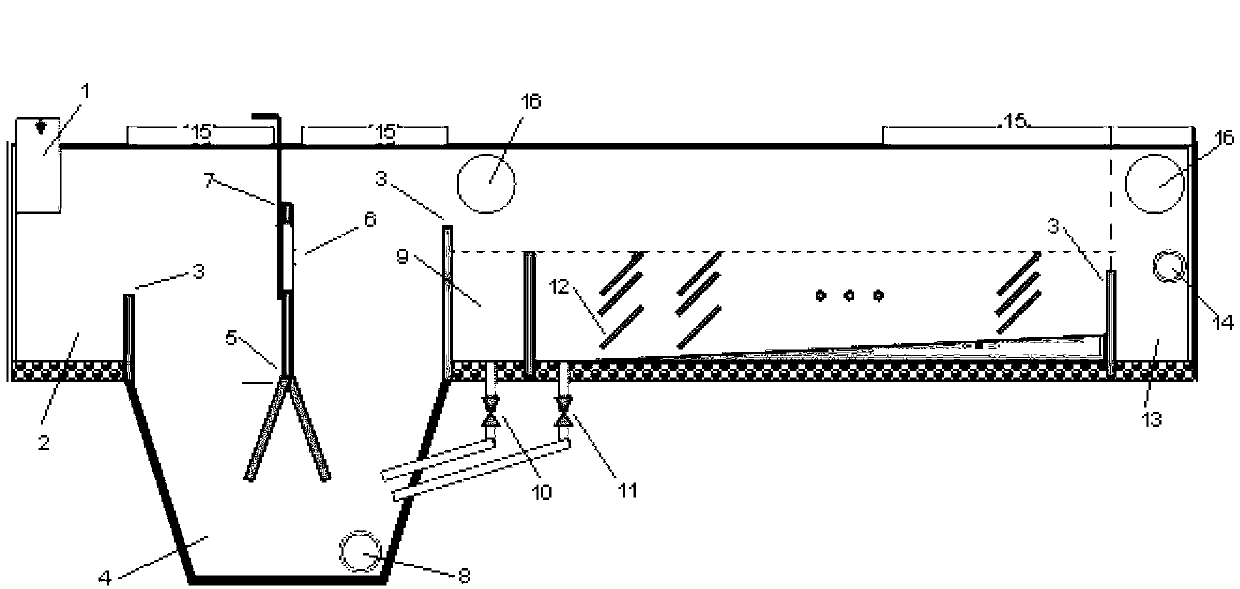

Embodiment 1

[0037] The canal thickener of this embodiment is a channel type as a whole. It includes a canal head a, a canal body b, and a canal tail c along the flow path of the slurry. There are partitions between the canal head a, canal body b, and canal tail c. 3 separate, and the partition 3 between the canal tail c and the canal body b is lower than the partition 3 between the canal head a and the canal body b to ensure the flow direction of the slurry from the canal head a to the canal tail c; The canal head a includes a feed port 1, a thick pool 4, and a discharge port 8. The slurry enters the thick pool 4 from the feed port 1, and the discharge port 8 is located at the bottom of the thick pool 4; and a surface is distributed in the canal body b. The settling sloping plate 12 facing the direction of the slurry flow and rising along the direction of the slurry flow, the bottom height of the canal body b rises in the direction of the water flow, and the bottom of the front end part is ...

Embodiment 2

[0040] In this example, the tailings discharged from the iron dressing plant, the amount of tailings discharged from the iron dressing plant is G=120m3 / h, and the concentration is 15%. The width of the canal b=1m, the height of the canal water level h=1m, and the number of settlement slopes in each group n=10, then it can be calculated

[0041] V 2 =G / (3600bh)=120 / (3600×1×1)=0.033333m / s

[0042] t=H / V 1 =(h / n) / V 1 =(1 / 10) / (0.33×10 -4 )=3030s

[0043] L=tV 2 =3030×0.033333=101m

[0044] The ore pulp enters the receiving pool 2 through the feeding port 1, and crosses the partition 3, and the heavy particles in the ore pulp settle in the thick pool 4. The dense pond 4 is divided into two parts on the left and the right by a herringbone 5, and the herringbone increases the tortuosity of the water flow and reduces the settlement height, thereby accelerating the settlement. A water-permeable window 6 is installed on the chevron to adjust the ratio of the amount of slurry flowing through t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com