Continuous settling tank

A settling tank, continuous technology, applied in the direction of settling tanks, liquid separation, chemical instruments and methods, etc., can solve the problems of reducing the cross-sectional area of the actual flow channel, increasing the velocity gradient of the flow system, multiple settlement areas, etc., to achieve faster relative The effect of speed of movement, utilization of internal space, and large settlement area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

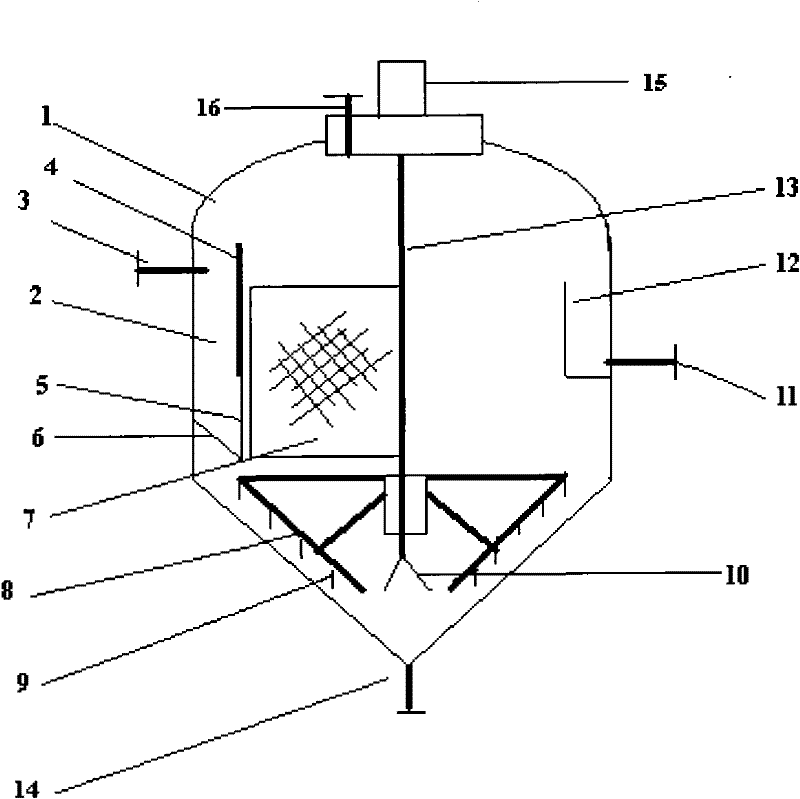

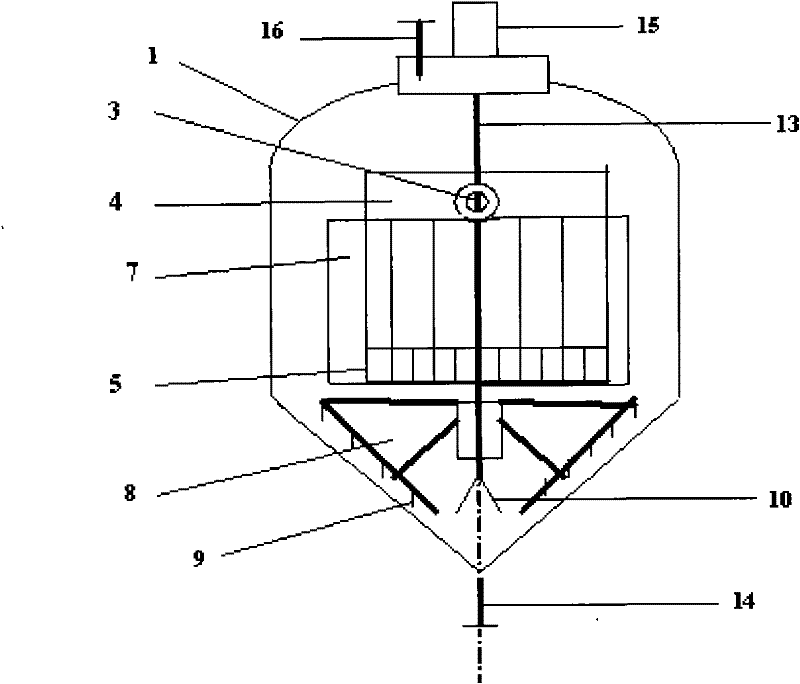

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

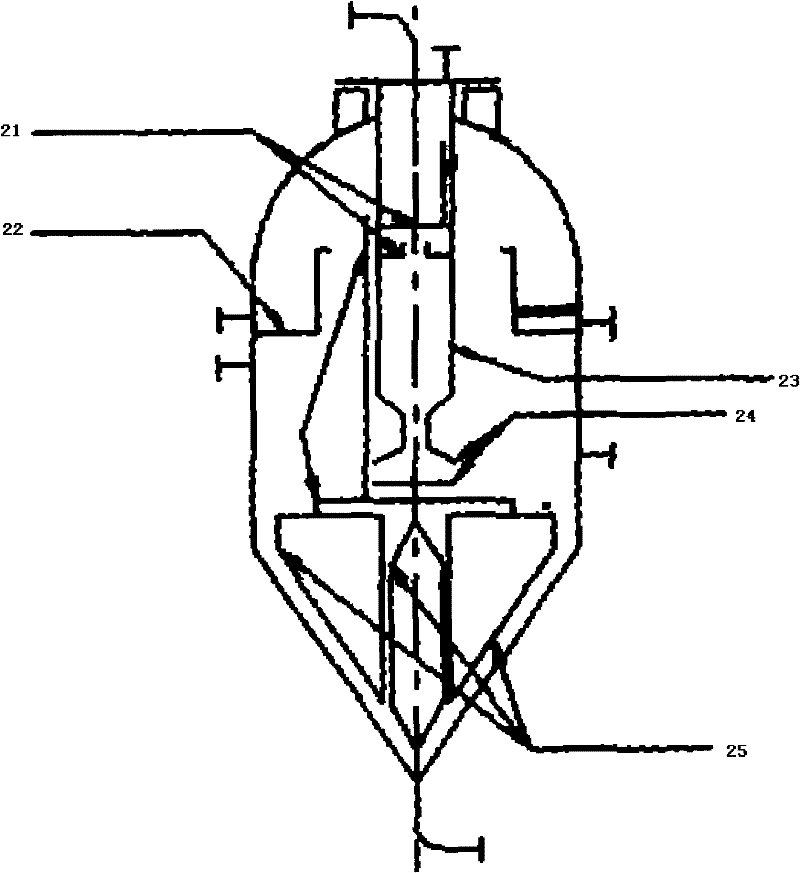

[0026] Such as figure 2 As shown, the settling tank includes a shell 1, the upper part of the shell 1 is a circular cylinder, and the lower part is a conical cylinder. Such as figure 2 , 3 As shown in and 4, a bow-shaped feed trough 2 is set in the circular cylinder of the housing 1, and a feed inlet 3 is set on the shell side wall of the bow-shaped feed trough 2. The bow-shaped feeding trough 2 is composed of the inner wall of the circular cylinder of the shell 1, the straight wall plate 4, the grid distribution plate 5 and the bottom plate 6, forming a bow-shaped top view, see Figure 5 . The chord length of the bow-shaped feed trough 2, that is, the ratio of the width L of the straight wall plate 4 to the diameter D of the circular cylinder is 0.35 to 0.75, which minimizes the area occupied by the feed trough while minimizing the mixing at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com