Integrated oil and turbidity removing device

An ontology and flocculation technology, applied in grease/oily substance/float removal devices, chemical instruments and methods, multi-stage water treatment, etc. The problem of high operating costs can improve the effect of flocculation and sedimentation, thoroughly discharge sludge and reduce the load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

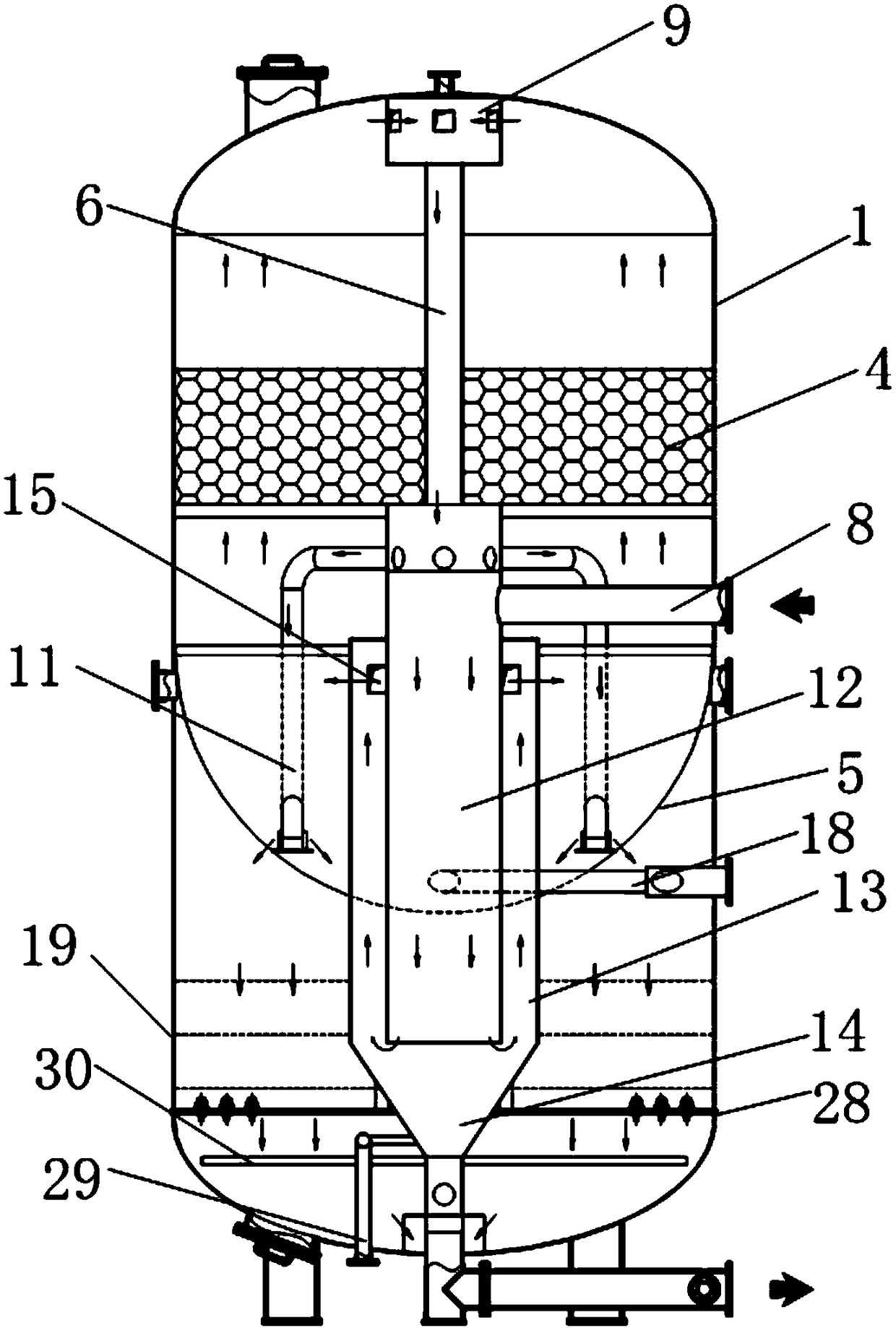

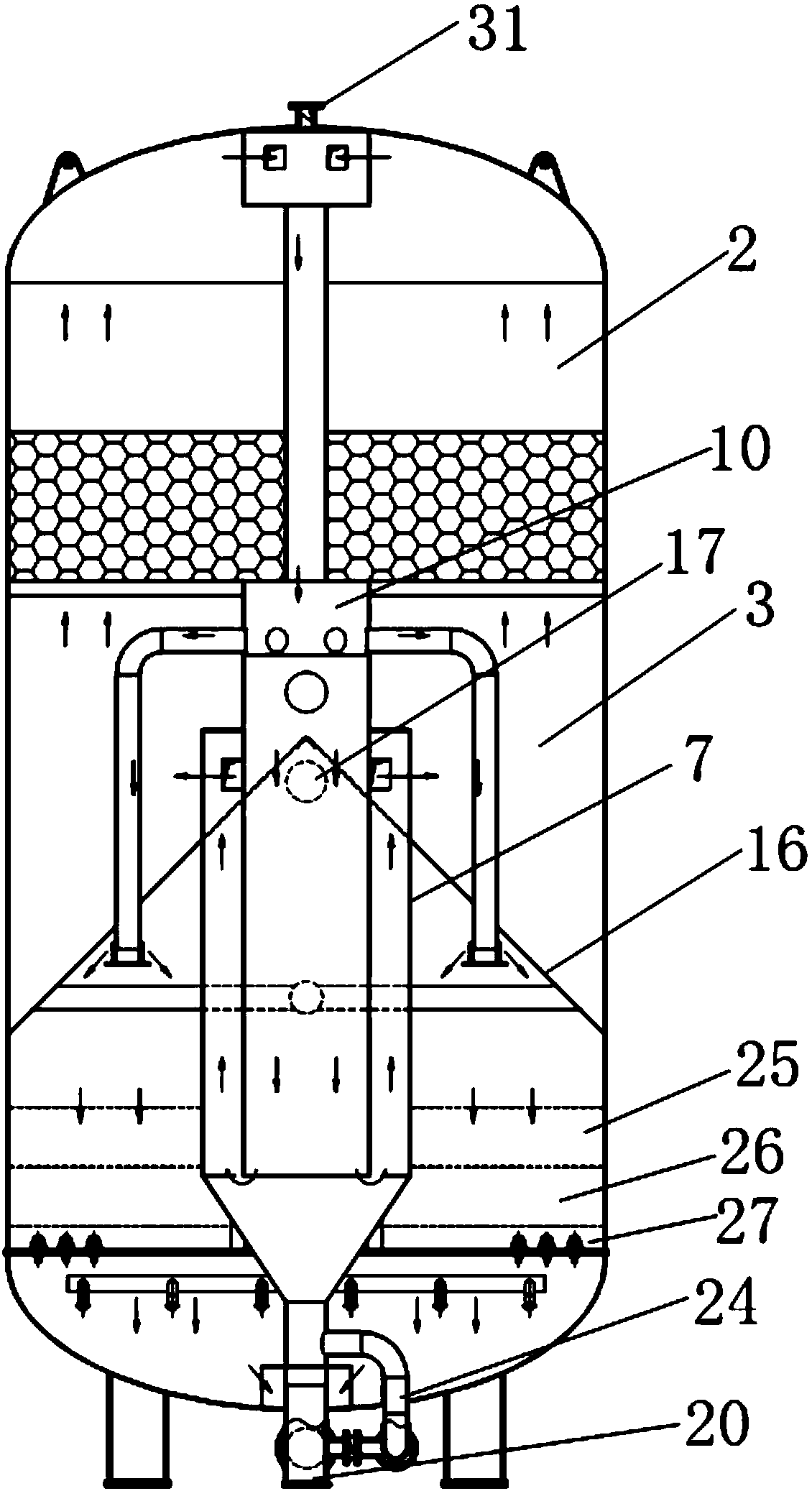

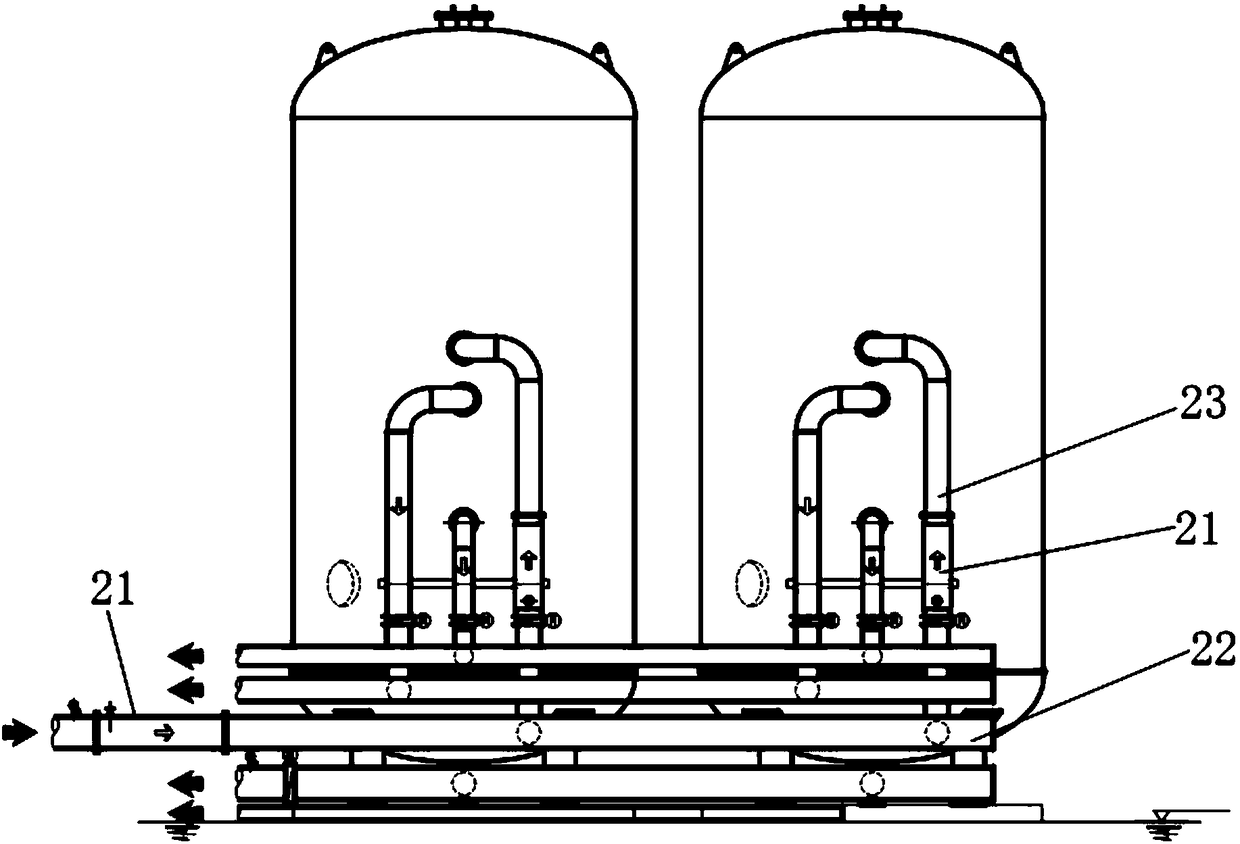

[0026] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0027] like figure 1 and figure 2 As shown, the integrated oil and turbidity removal device includes a device body 1. The upper part of the device body 1 is a clarification area 2, and the lower part is a mud fall area 3. The lower part of the clarification area 2 is provided with a porous spherical filler 4. The mud A symmetrical mud collecting bucket 5 is arranged under the drop zone 3, a center pipe 6 and a flocculation reaction chamber 7 are arranged in the center of the device body 1, the flocculation reaction chamber 7 is connected to a water inlet pipe 8, and the upper end of the center pipe 6 is a collector Water tank 9, the lower end of which is a water d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com