A kind of wet method continuous grading equipment and grading method for flaky particles

A flaky particle, wet process technology, applied in the field of solid particle wet classification equipment, can solve the problems of slow sedimentation speed of classified particles, large area of sedimentation equipment, and large amount of product fine powder entrainment, so as to reduce the amount of entrainment, The effect of shortening the settlement distance and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

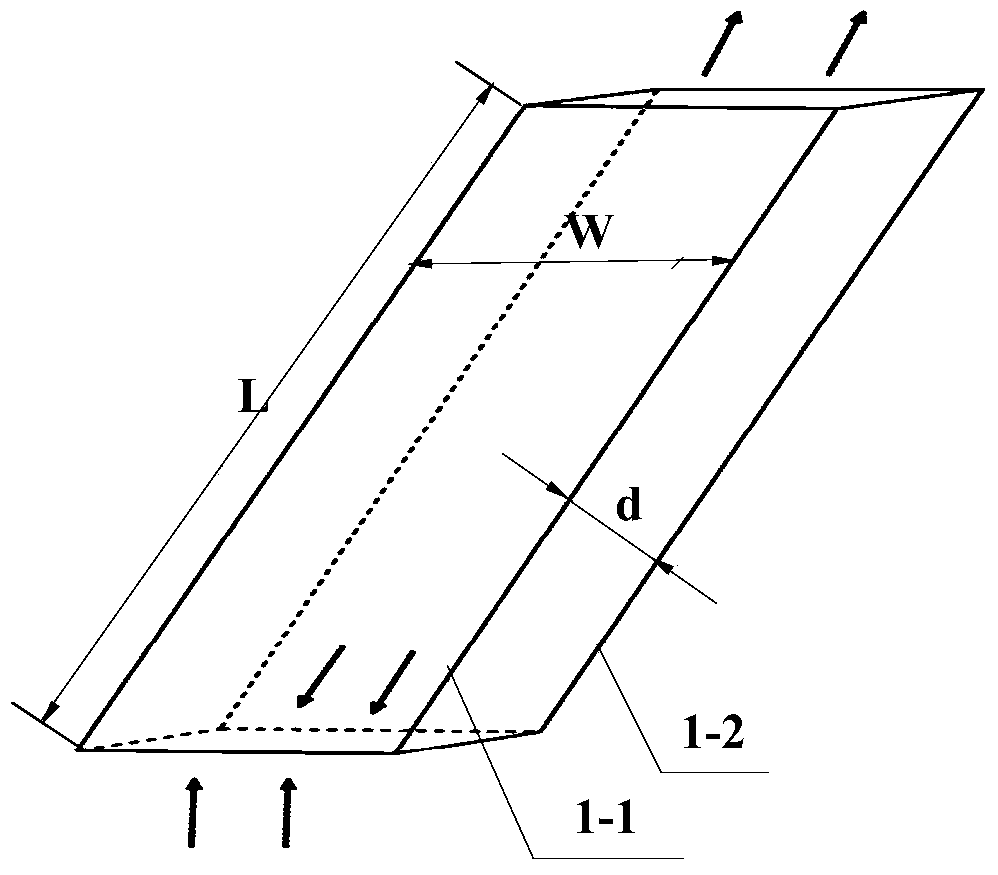

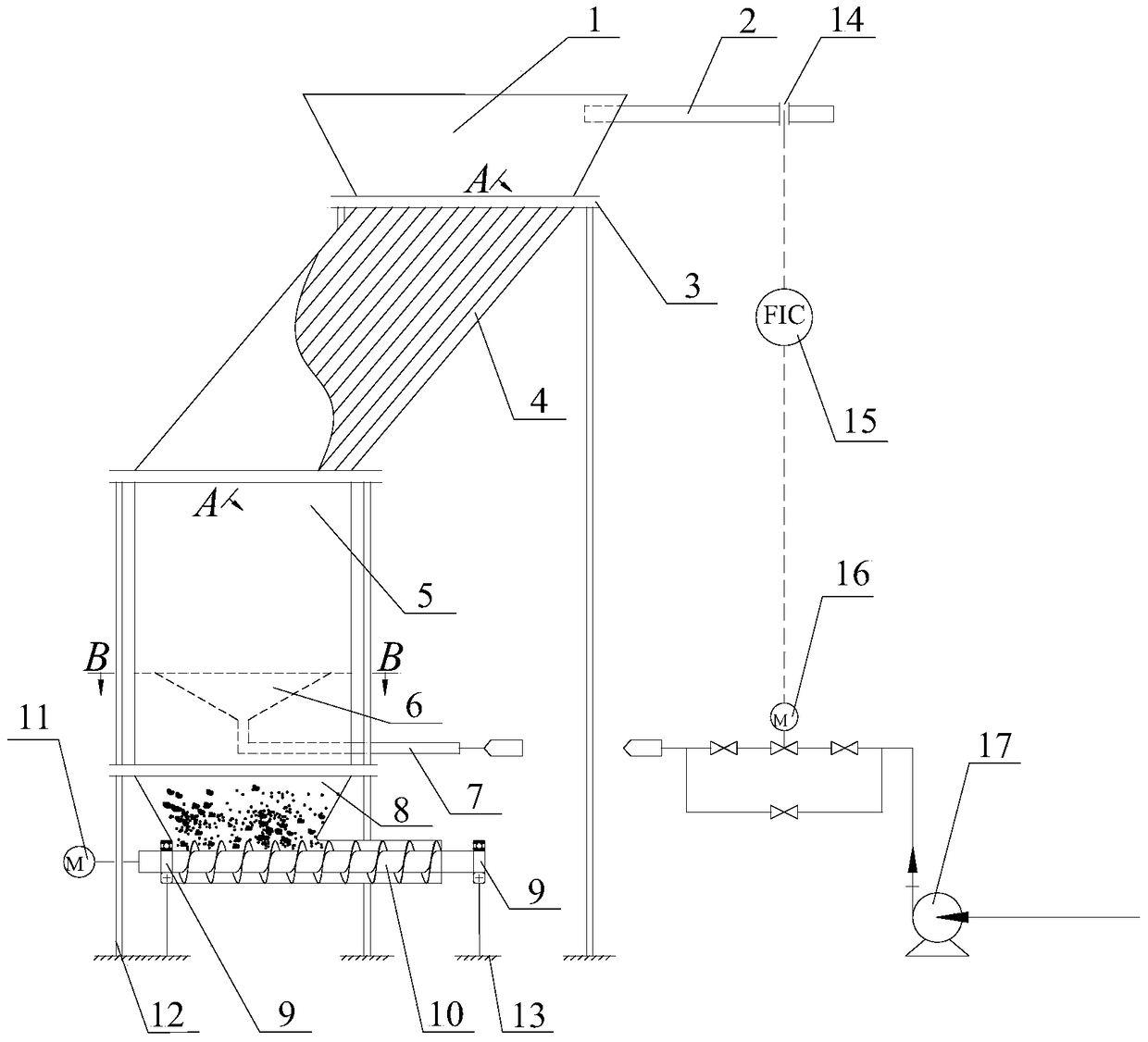

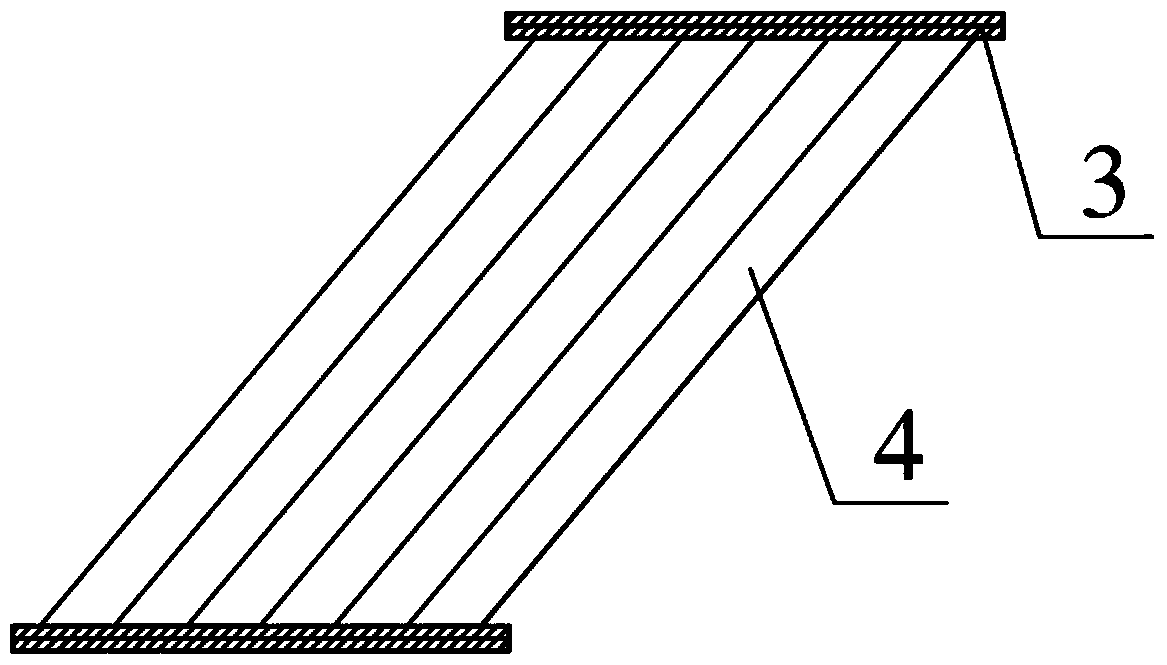

[0058] The raw material is artificially synthesized fluorphlogopite mica powder after grinding, with a density of 2.88g / cm 3 , Raw material particle size distribution: D 90 = 251.724 μm, D 50 = 77.11 μm, D 10 =23.314μm; the solid content of the prepared suspension is 12.70%; the main dimensions of the equipment are as follows figure 1 , 2 , 3, and 4: the space between the upper inclined plate 1‐1 and the lower inclined plate 1‐2 is d=7mm, the length L of the upper inclined plate 1‐1 or the lower inclined plate 1‐2 is 2000mm, and the upper The inclination angle α of the inclined plate 1-1 or the lower inclined plate 1-2 is 45°, the width w of the upper inclined plate 1-1 or the lower inclined plate 1-2 is 500mm, and the diameter of the circular hole 6-5 on the distribution plate is 4mm.

[0059]Classification process: prepare artificially synthesized fluorphlogopite powder suspension with a solid content of 12.70%, add sodium pyrophosphate dispersant, the content of sodium...

Embodiment 2

[0065] The raw material is ground natural mica powder with a density of 3.00g / cm 3 , Raw material particle size distribution: D 90 = 240.793 μm, D 50 =80.578μm, D 10 =23.743μm; the solid content of the prepared suspension is 7.77%; the main dimensions of the equipment are as follows figure 1 , 2 , 3, and 4: the partition spacing between the upper inclined plate 1-1 and the lower inclined plate 1-2 = 35mm, the length L of the upper inclined plate 1-1 or the lower inclined plate 1-2 = 1500mm, the upper The inclination angle α of the inclined plate 1-1 or the lower inclined plate 1-2 is 55°, the width w of the upper inclined plate 1-1 or the lower inclined plate 1-2 is 500mm, and the diameter of the circular hole 6-5 on the distribution plate is 4mm. The classification process is the same as in Example 1, and the raw material is classified into six sections five times. The particle size distribution of each section after the raw material and classification is as shown in Tab...

Embodiment 3

[0070] The raw material is flake aluminum powder obtained after grinding, with a density of 2.70g / cm 3 , Raw material particle size distribution: D 90 = 318.447 μm, D 50 = 92.971 μm, D 10 =26.495μm; the solid content of the prepared suspension is 4.44%; the main dimensions of the equipment are as follows figure 1 , 2 , 3, and 4: the partition spacing between the upper inclined plate 1-1 and the lower inclined plate 1-2 = 35mm, the length L of the upper inclined plate 1-1 or the lower inclined plate 1-2 = 1500mm, the upper The inclination angle α of the inclined plate 1-1 or the lower inclined plate 1-2 is 55°, the width w of the upper inclined plate 1-1 or the lower inclined plate 1-2 is 500mm, and the diameter of the circular hole 6-5 on the distribution plate is 4mm. The classification process is the same as in Example 1, and the raw material is classified into five sections four times. The raw material and the particle size distribution of each section after classifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com