Special-shaped inclined plane countercurrent sorting device

A technology of sorting device and slope, which is applied in the field of special-shaped slope countercurrent sorting device, to achieve the effect of improving recovery rate and sorting efficiency, and increasing settlement area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

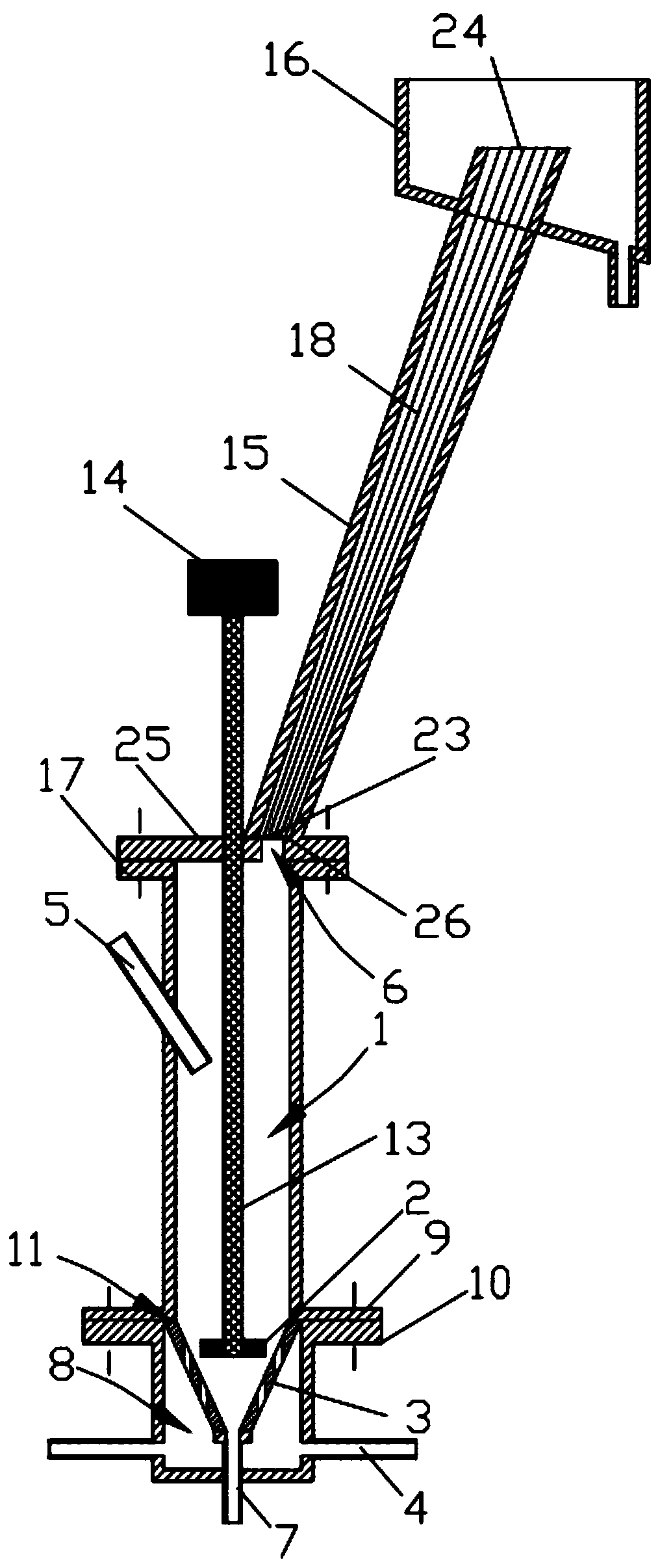

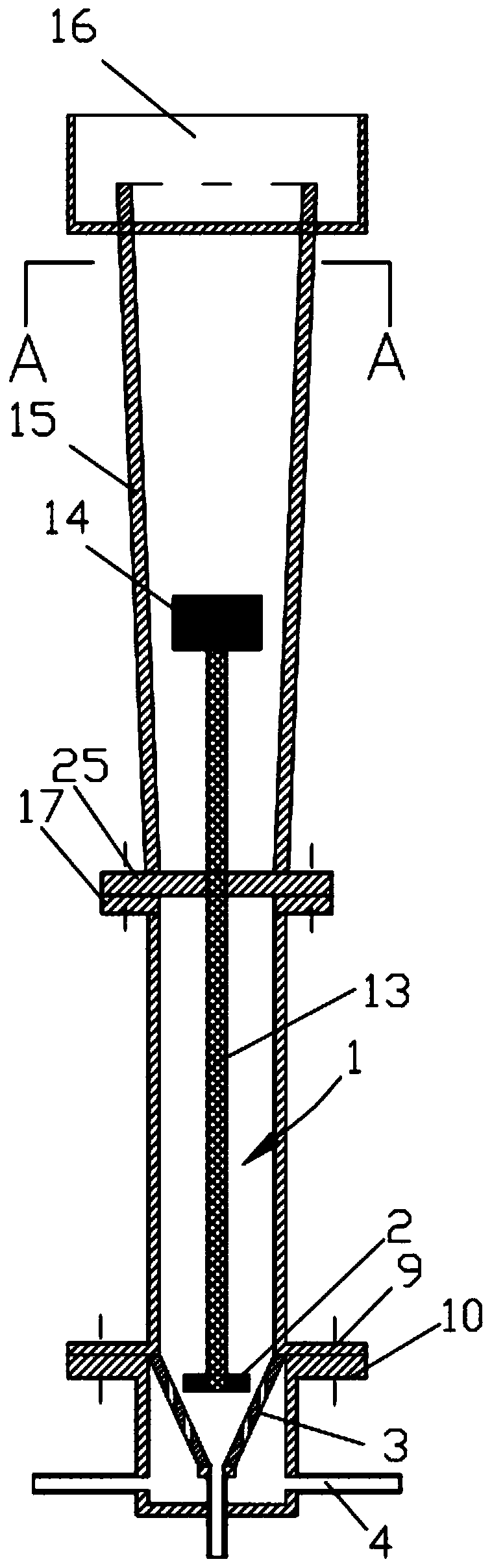

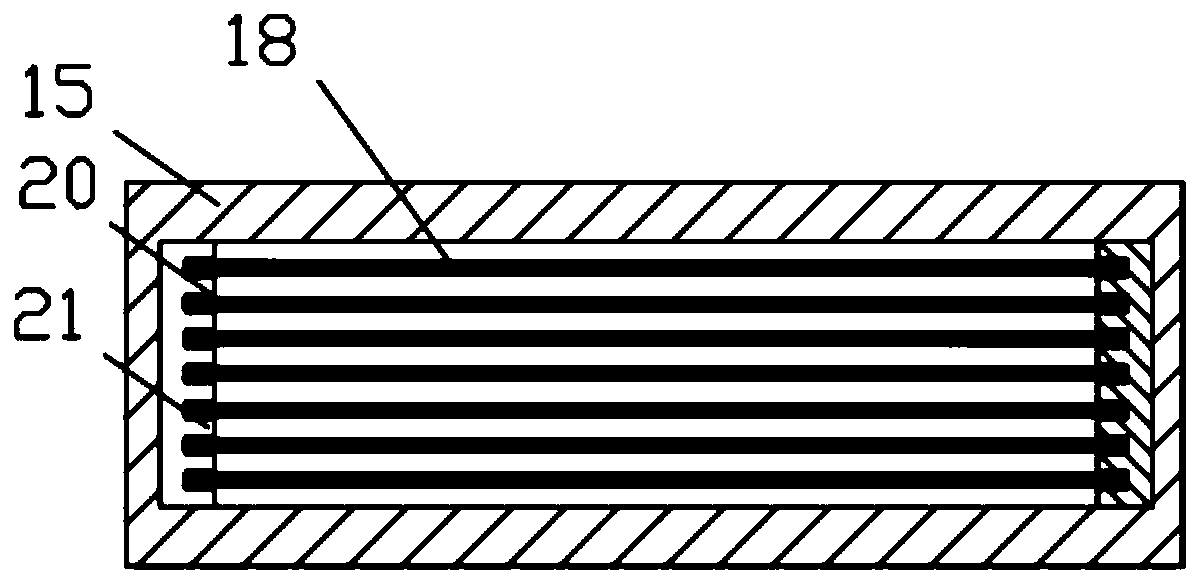

[0028] like Figure 1-6 As shown, the present invention discloses a special-shaped inclined-plane countercurrent sorting device, including a sorting chamber 1 with a cavity inside, a stirring impeller 2 and a water distribution member 3 installed in the sorting chamber 1, and the sorting chamber 1 is located in the water distribution The bottom of the part 3 is provided with a water inlet 4, and the water inlet 4 is connected with an external water pump. The upper part of the sorting chamber 1 is provided with a feed port 5, and the top of the feed port 5 is provided with a floating particle outlet 6. The water distribution part 3 It is an inverted cone structure, the upper end of the water distribution member 3 faces the stirring impeller 2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com