Arrangement structure and method of inclined tube bodies in inclined tube thickener

A concentrator and inclined pipe technology, which is applied in the field of arrangement structure of inclined pipe bodies, can solve the problems of reduction of effective settlement area, difficulty in arranging inclined pipe bodies, loose and rough appearance, etc., so as to achieve a simple arrangement method and effective settlement of equipment. The effect of increased area and improved appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

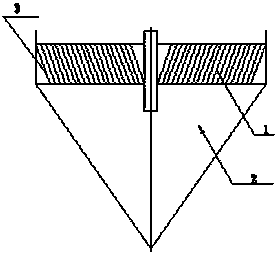

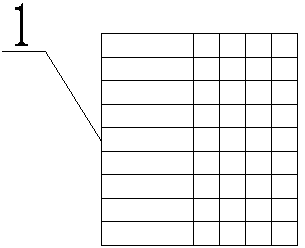

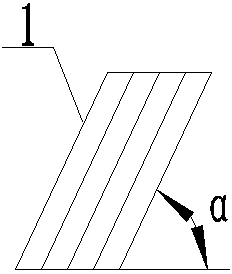

[0023] An arrangement structure of inclined tube bodies in an inclined tube concentrator, see Figure 1-Figure 4 , the inclined tube body is arranged in the concentration tank of the inclined tube concentrator. The inclined tube body 1 of this embodiment is an inclined cuboid, which is closely arranged in multiple straight lines in the concentration pool 2 of the inclined tube concentrator. The inclined tube body 1. The inclination angle α in the concentration tank of the inclined tube concentrator is 65-70 degrees, which is 65 degrees in this embodiment. In the concentration pool 2 of the inclined tube concentrator, the inclined tube body 1 in the shape of a cuboid is placed in the concentration pool 2 of the inclined tube concentrator. In the concentration pool 2 of the circular inclined tube concentrator, when the area of a single arc-shaped sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com