Disc stack centrifuge provided with single centripetal pump with spiral acceleration function and centrifugal equipment

A technology of helical acceleration and centrifuge, applied in centrifuges and centrifuges with rotating drums, etc., can solve the problems of low separation efficiency, and achieve the effects of expanding the sedimentation area, enhancing the separation effect, and shortening the sedimentation distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

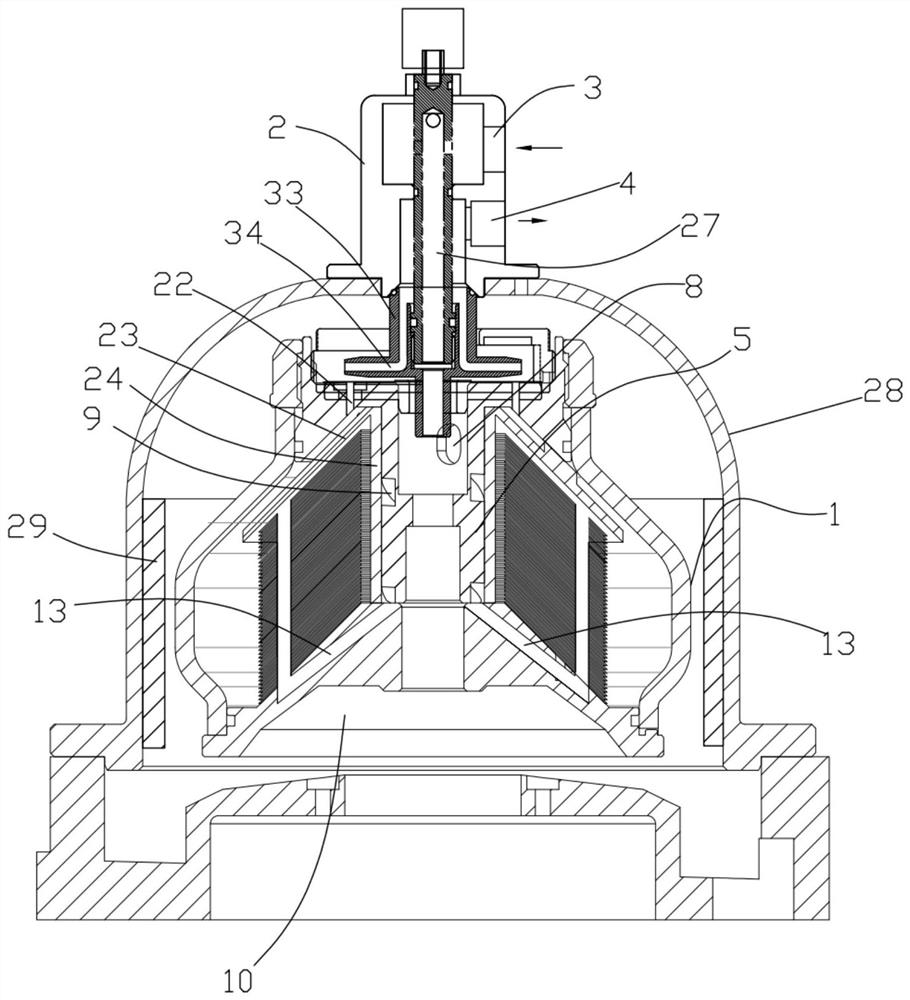

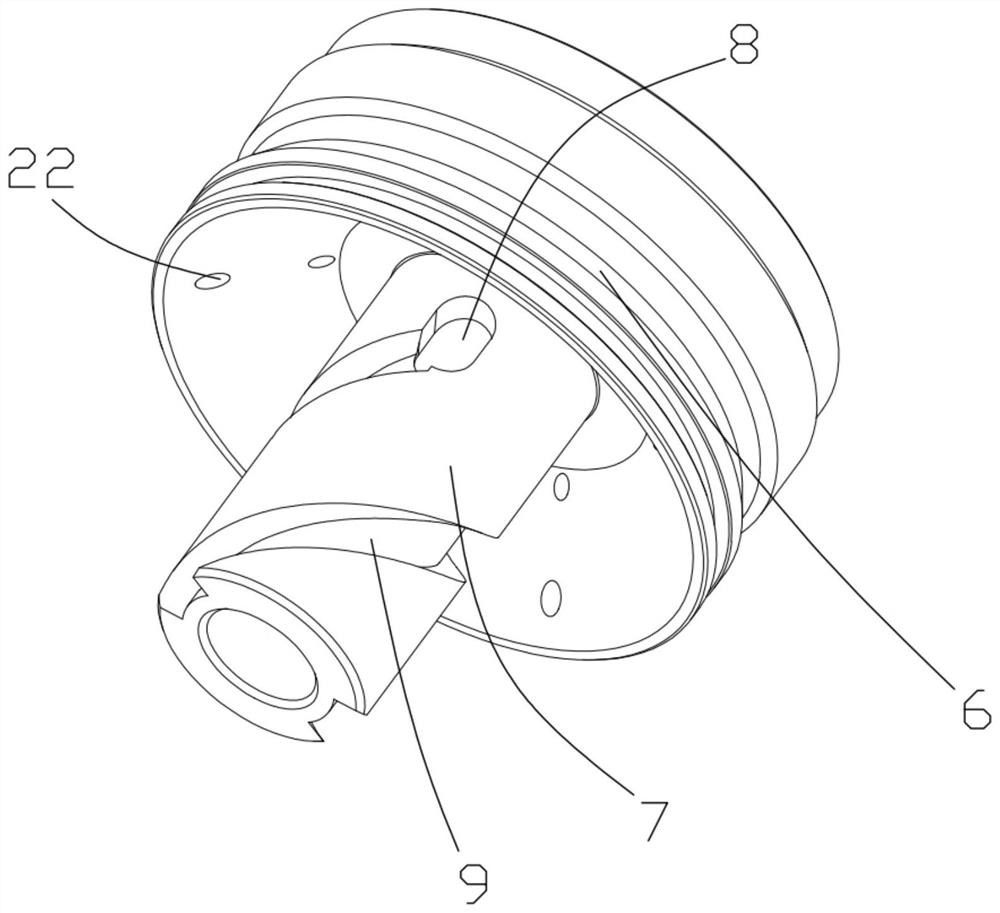

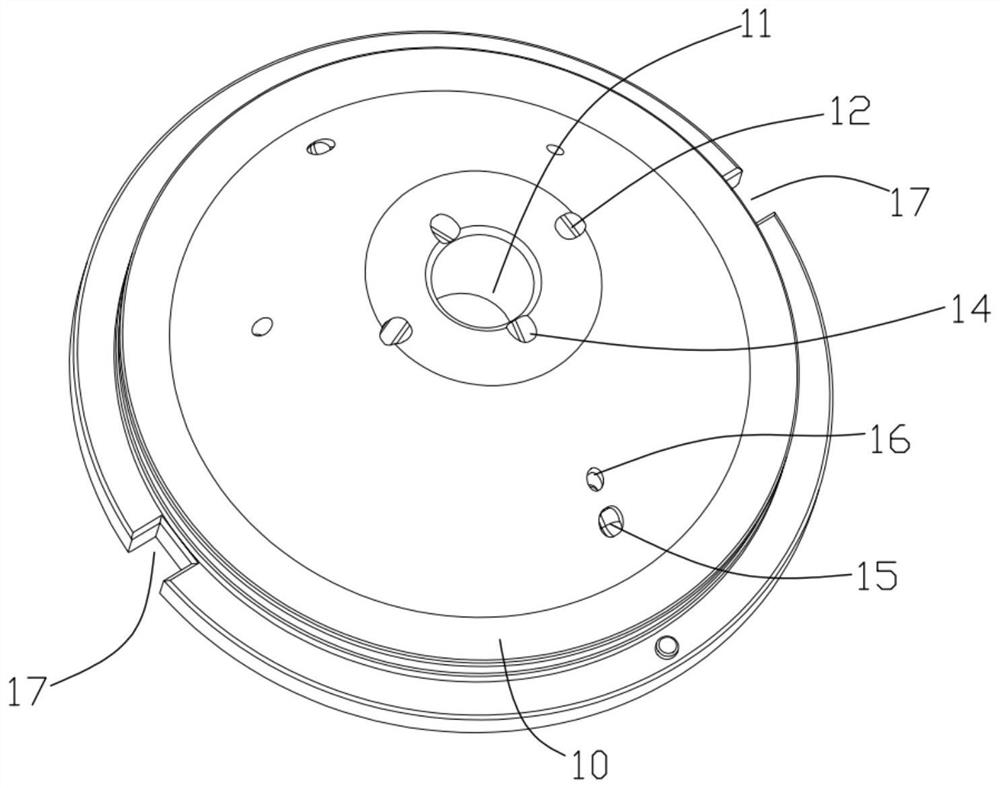

[0043] Such as figure 1 As shown, the present invention proposes a unidirectional heart disc centrifuge with spiral acceleration, including a drum 1, which is a common structure in the prior art, and forms an annular structure that can collect waste residue through the action of centrifugal force, so The top of the drum 1 is provided with a liquid inlet and outlet cover 2, which is used to pass in the mixed liquid and to discharge the light liquid. The liquid inlet and outlet cover includes a mixed liquid inlet pipe and a light liquid outlet pipe , a valve stem 27 is inserted into the top of the liquid inlet and outlet cover, the valve stem 27 is a hollow structure, and a slot is provided on the side wall, the mixed liquid inlet pipe communicates with the slot, and the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com