Nitrogen-containing organic wastewater electrochemical treatment reactor and method for enabling electroflocculation sludge to achieve magnetic separation performance

A technology of electrocoagulation and magnetic separation, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as difficult maintenance and high operating costs, and achieve improved treatment efficiency, The effect of speeding up the separation time and facilitating the separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

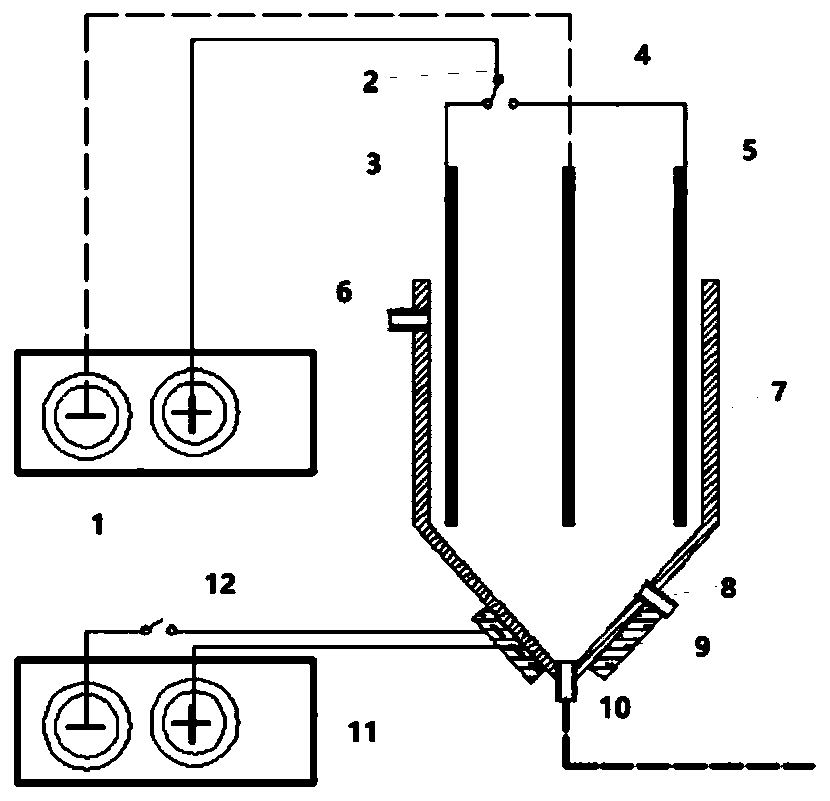

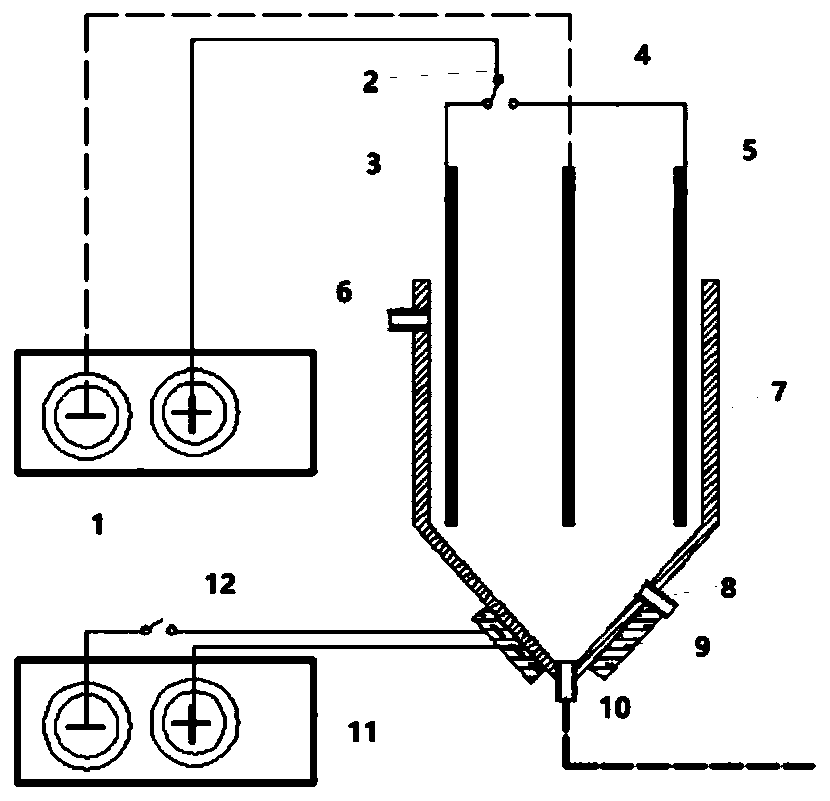

[0034] As shown in the accompanying drawings of the description, a nitrogen-containing organic wastewater electrochemical treatment reverse device that enables electro-flocculation sludge to obtain magnetic separation performance. When the power is turned on, the two anodes of the electrochemical system work in the order of iron anode→Ti / RuO 2 Anode→Iron anode→Ti / RuO 2 Anode→Iron anode→Ti / RuO 2 Anode → iron anode. Anode alternation time is 20min, electrolysis is 140min, current density is 100mA / cm 2 , take samples to test the treatment effect.

[0035] Under the above conditions, the biochemical effluent of landfill leachate is selected as the experimental object (because it has all the characteristics of nitrogen-containing organic wastewater), after the sewage is treated by the reactor of the present invention, the effluent COD removal rate is 75.5%, and the TN removal rate is 94.9% %.

Embodiment 2

[0037] The reactor is set up as in Example 1, with the actual landfill leachate biochemical effluent as the experimental object (because it has all the characteristics of nitrogen-containing organic wastewater), after the sewage is treated by the reactor of the present invention, the main stability obtained under the iron anode condition Crystal form is Fe 3 o 4 , in Ti / RuO 2 The stable crystal form obtained under anodic conditions is γ-Fe 2 o 3 , after 140min of reaction, magnetic separation was carried out on the precipitate, and the separation time was 24s through a 1T magnetic field.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com