Rosin production process

A production process and technology for rosin, applied in the field of forest product chemical manufacturing, can solve problems such as affecting the quality of rosin products, unfavorable clarification of rosin slag water, inability to separate sewage and slag, etc., and achieve the effects of short time, reduced discharge, and reduced loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

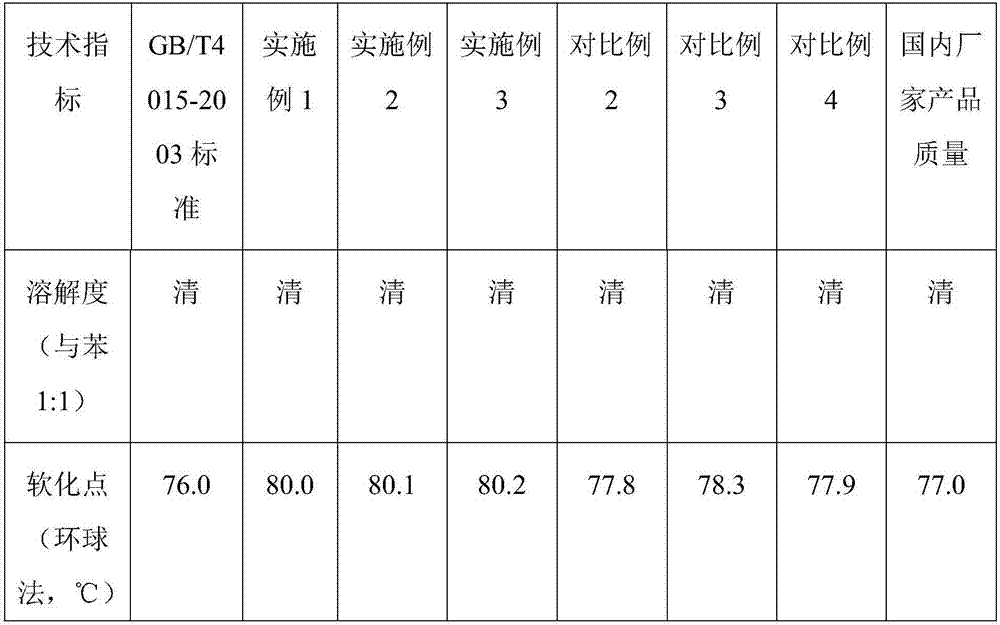

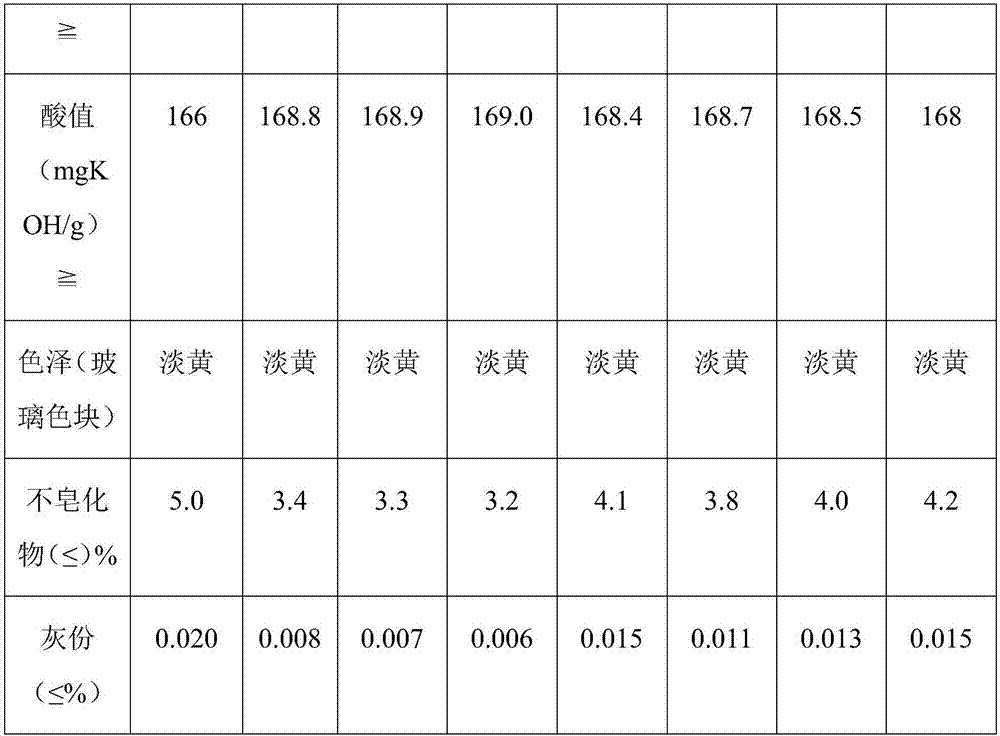

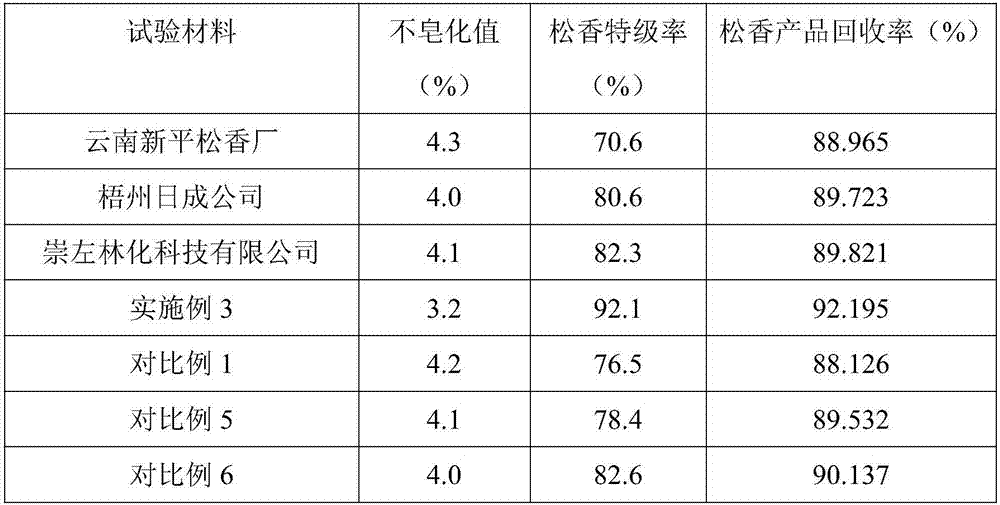

Examples

Embodiment 1

[0044] Embodiment 1, a kind of rosin production technology

[0045] Described rosin production technique, comprises the following steps:

[0046] S1 sends the pine resin into the dissolving pot, uses two dissolving pots to dissolve intermittently, feeds water vapor heating at the bottom of the dissolving pot to make the rosin dissolve in the dissolving solution in the dissolving pot, and the dissolving solution addition is 32% of the above-mentioned rosin weight, dissolves The temperature is 96°C, and the dissolved fat liquid is obtained;

[0047] S2 Wash the dissolved fat liquid obtained in step S1 with water, the amount of water added for washing is 100L / h, the water temperature is 92°C, and the sewage and residue in the lower layer are discharged to obtain the upper layer of fat liquid after washing;

[0048] S3 sends the washed upper layer fat liquid obtained in step S2 into a high-efficiency clarification tank for clarification, and discharges the slag water at the botto...

Embodiment 2

[0052] Embodiment 2, a kind of rosin production process

[0053] Described rosin production technique, comprises the following steps:

[0054] S1 sends turpentine into the dissolving pot, uses two dissolving pots to dissolve intermittently, feeds water vapor heating at the bottom of the dissolving pot to make the rosin dissolve in the dissolving solution in the dissolving pot, and the dissolving solution addition is 38% of the above-mentioned rosin weight, dissolves The temperature is 100°C, and the dissolved fat liquid is obtained;

[0055] S2 Wash the dissolved fat liquid obtained in step S1 with water, the amount of water added for washing is 800L / h, the water temperature is 98°C, and the sewage and residue in the lower layer are discharged to obtain the upper layer of fat liquid after washing;

[0056] S3 sends the washed upper layer fat liquid obtained in step S2 into a high-efficiency clarification tank for clarification, and discharges the slag water at the bottom to o...

Embodiment 3

[0060] Embodiment 3, a kind of rosin production process

[0061] Described rosin production technique, comprises the following steps:

[0062] S1 sends turpentine into the dissolving pot, uses two dissolving pots to dissolve intermittently, feeds water vapor heating at the bottom of the dissolving pot to make the rosin dissolve in the dissolving solution in the dissolving pot, and the dissolving solution addition is 36% of the above-mentioned rosin weight, dissolves The temperature is 98°C, and the dissolved fat liquid is obtained;

[0063] S2 Wash the dissolved fat liquid obtained in step S1 with water, the amount of water added for washing is 400L / h, the water temperature is 95°C, and the sewage and residue in the lower layer are discharged to obtain the upper layer of fat liquid after washing;

[0064] S3 sends the washed upper layer fat liquid obtained in step S2 into a high-efficiency clarification tank for clarification, and discharges the slag water at the bottom to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com