Device for separating capsule caps and capsule bodies, and capsule screening equipment

A technology for screening equipment and capsules, applied in solid separation, sieves, grids, etc., can solve the problems of slow disassembly, complicated follow-up processing of recovered drugs, labor and time consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

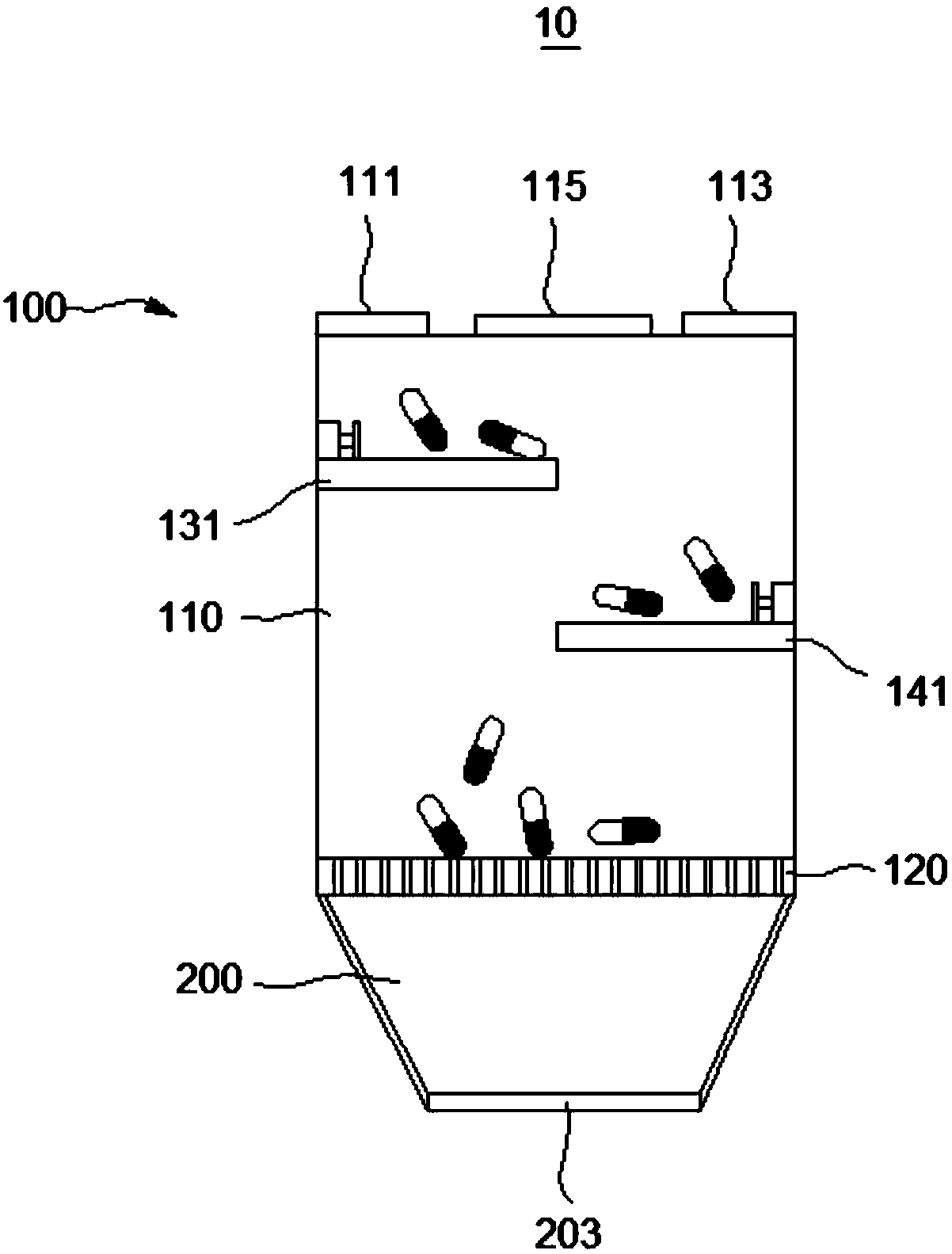

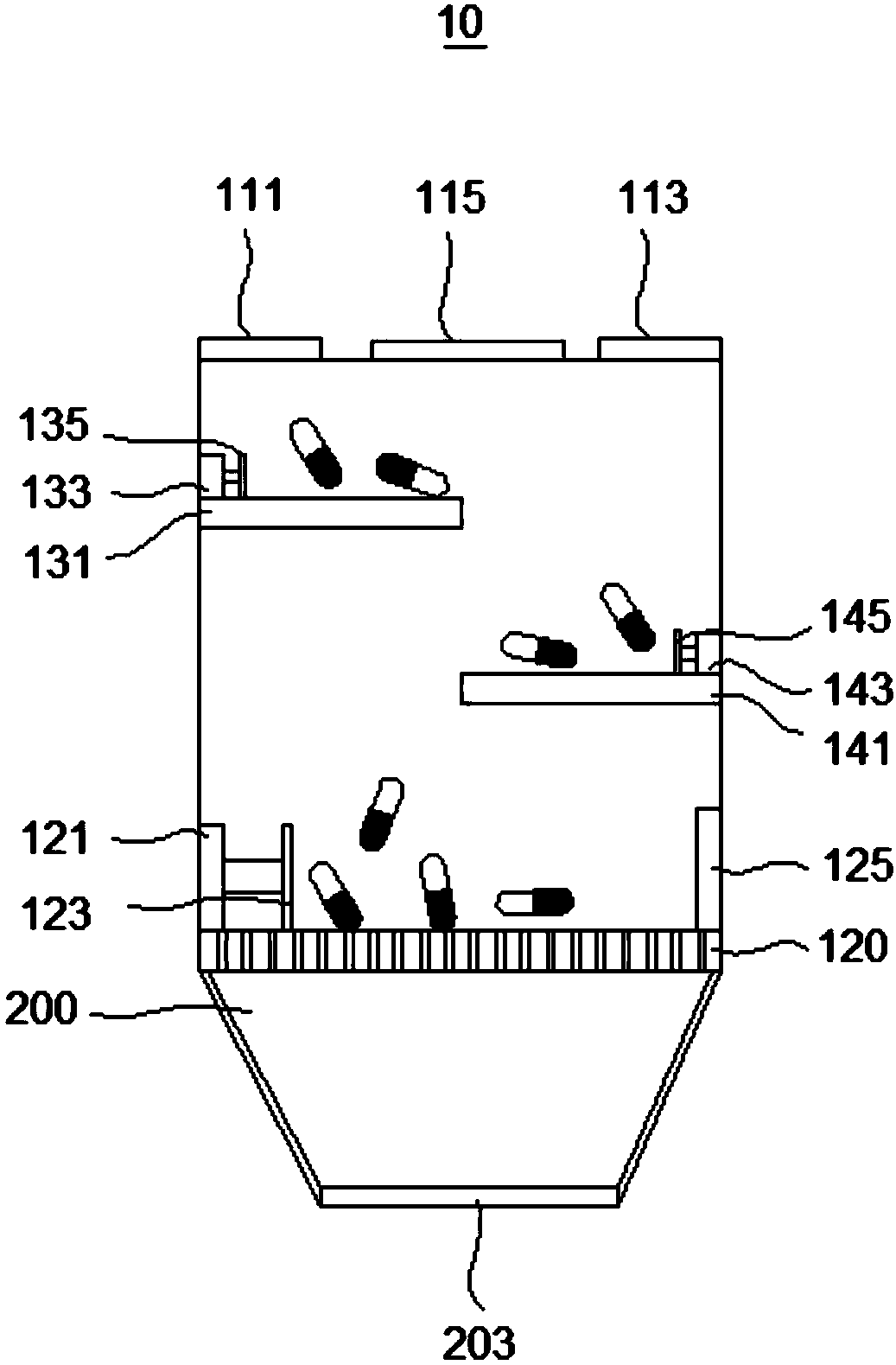

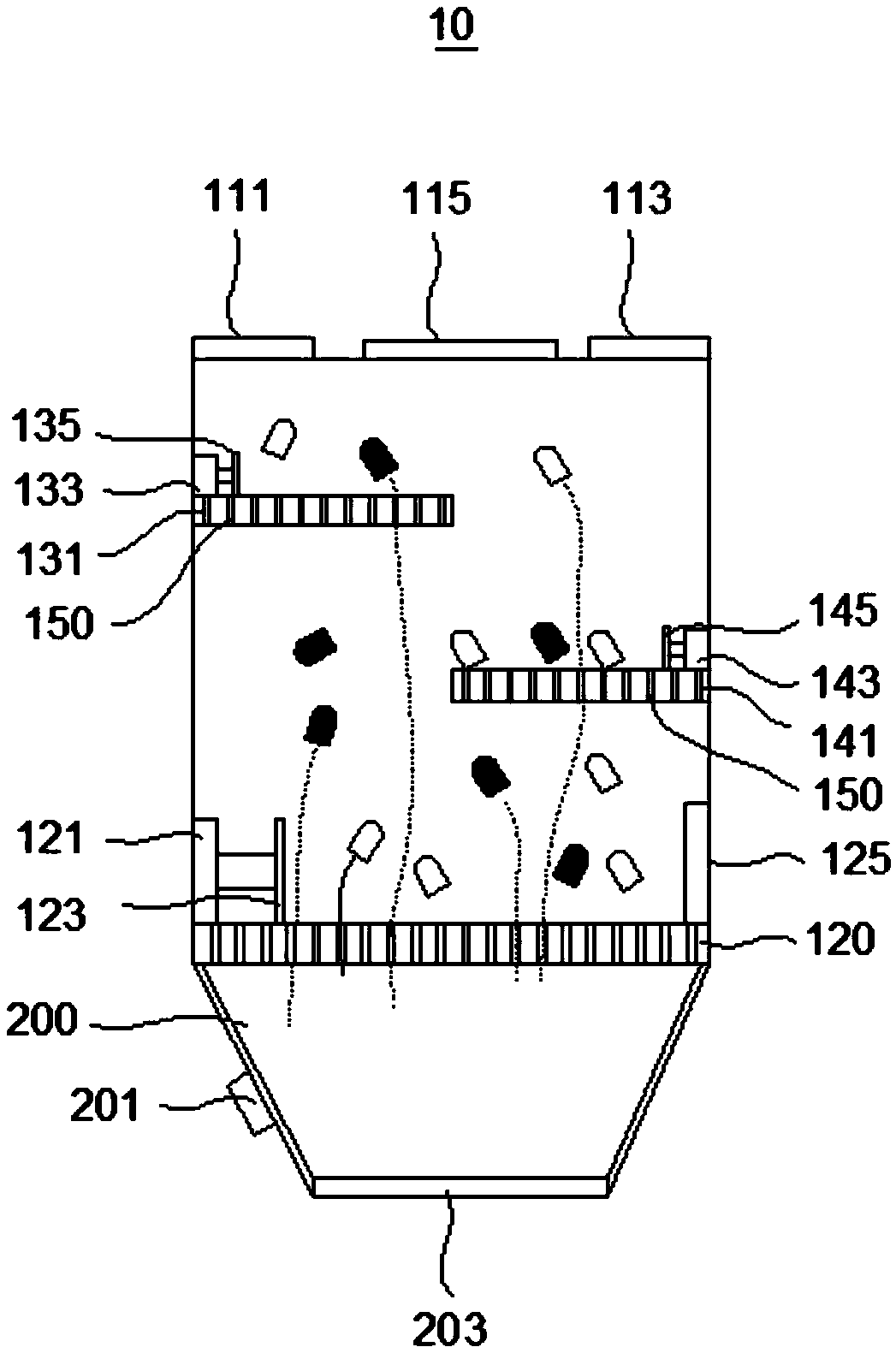

[0038] Please refer to Figure 1~2 , the present embodiment provides a device 10 for separating a capsule cap and a capsule body, which includes a hollow sub-capsule body 100 , a capsule screening plate 120 and a capsule partition assembly. The device has the advantages of being able to separate nested capsule caps and capsule bodies in batches and recover pure medicine effectively.

[0039] Specifically, the capsule sieve plate 120 is connected to the inner side wall of the sub-capsule main body 100 and the capsule sieve plate 120 separates the sub-capsule main body 100 into a separation chamber 110 and a collection chamber 200 which are sequentially connected from bottom to bottom. An air inlet 111 communicating with the pressurization device, an exhaust port 113 for depressurization and an inlet 115 for adding capsules into the separation chamber 110.

[0040] The separation chamber 110 is a position for separating the fitted capsule cap and capsule body, so as to recover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com