Device and method for preparing injection coal through impurity removal and flotation after meager coal and meager lean coal crushing

A flotation device and a technology for lean and lean coal are applied in the field of devices for crushing lean coal, removing impurities and flotation to obtain blown coal after lean and lean coal, and can solve problems such as dust pollution and achieve pollution reduction, ease of use, and efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

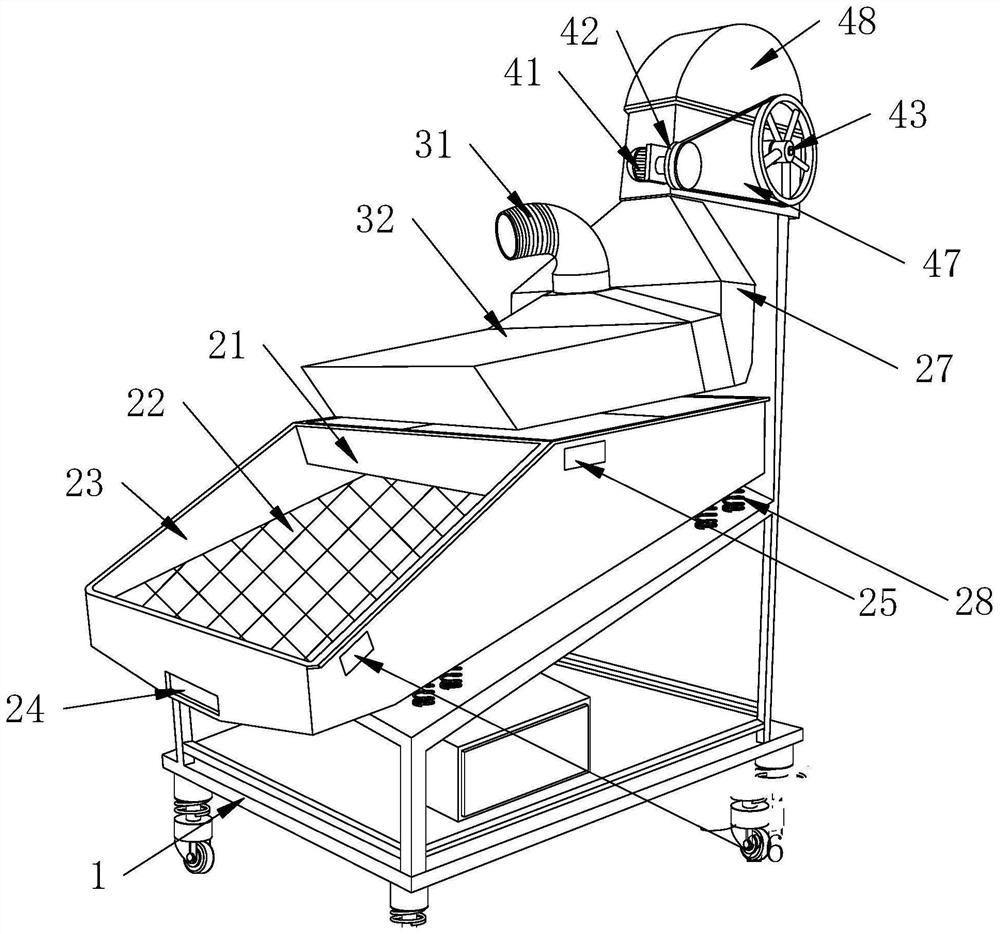

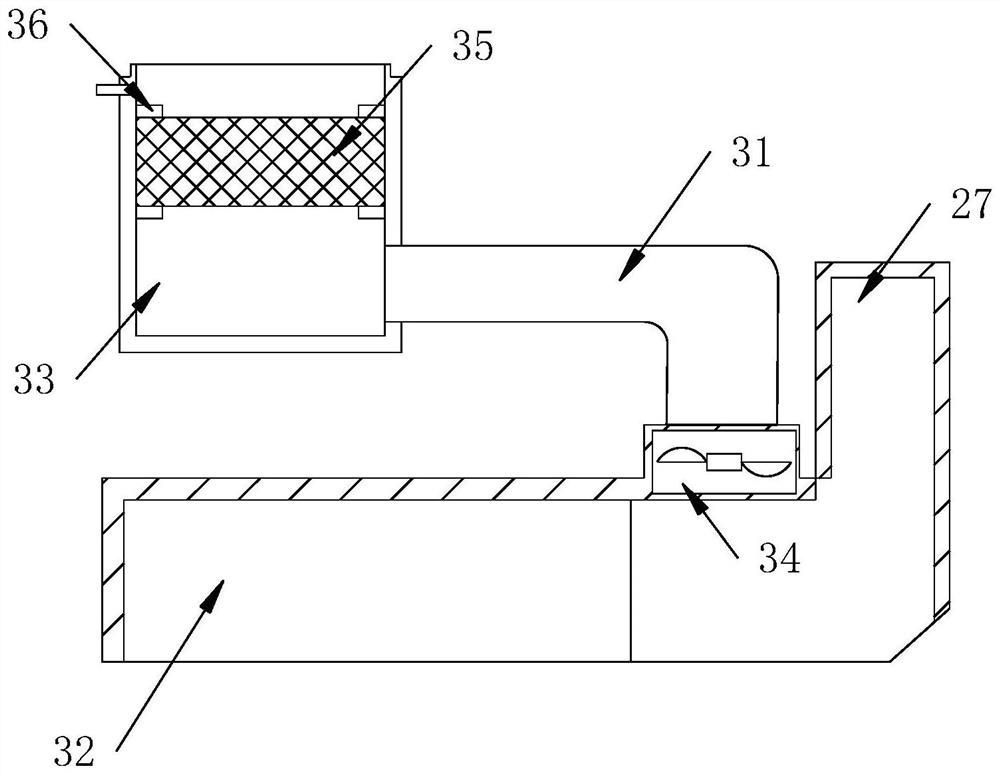

[0052] Such as Figure 1 to Figure 6 As shown, the device for crushing lean coal and lean coal and removing impurities and flotation to produce PCI coal in this embodiment includes a crushing and removing device and a flotation device arranged in sequence, and the crushing and removing device includes a moving frame 1 And the shearing and crushing mechanism, impurity removal mechanism and dust suction mechanism arranged on the mobile frame 1;

[0053] The shearing and crushing mechanism includes a cabinet 47 installed on the top of one side of the mobile frame 1, a shearing and crushing assembly arranged in the cabinet 47, and a shearing and crushing assembly arranged on the outer wall of the cabinet 47 and used to drive the shearing and crushing assembly for lean coal and coal. A drive assembly for shearing and crushing lean coal; the top of the cabinet 47 is connected with a material guide cover 48, and the top of the material guide cover 48 is provided with a feed port;

...

Embodiment 2

[0067] The method for producing PCI coal by crushing lean coal and lean coal after removing impurities and flotation, the method includes the following steps:

[0068] Step 1, placing the crushing and impurity removal device and the flotation device side by side, and connecting the discharge port 24 of the crushing and impurity removal device with the feed port of the flotation device;

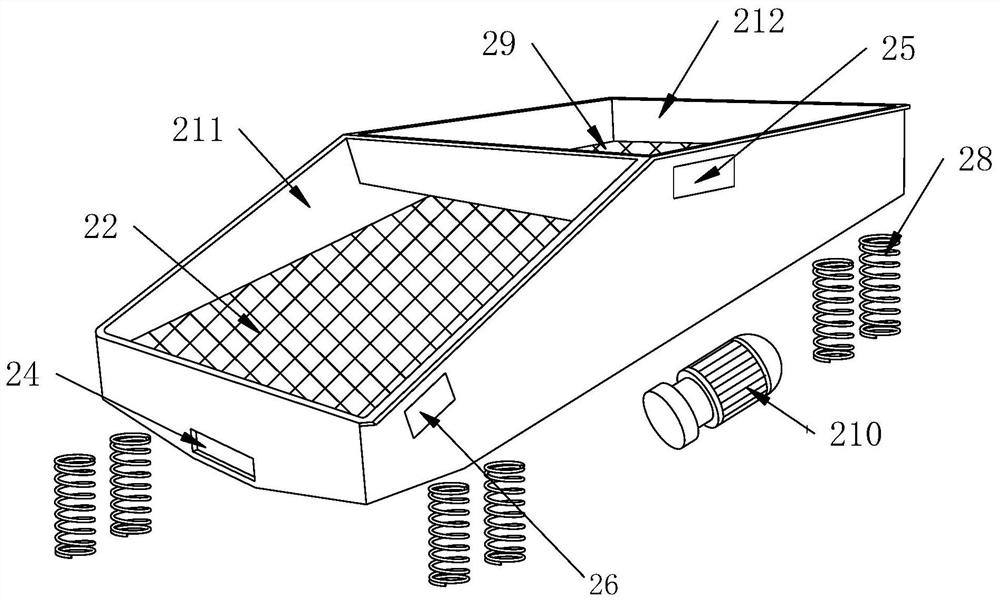

[0069]During specific implementation, the installation process of the crushing and impurity removal device is: first select the impurity removal screen one 22 and the impurity removal screen two 29 of appropriate size, and the impurity removal screen one 22 and the impurity removal screen two 29 respectively Installed in the impurity removal area one 211 and the impurity removal area two 212 of the open impurity removal box 23, then the filter screen 213 is installed in the cabinet 47, and the rotating rod 44 together with the scraper 45 and the blade 46 are installed in the cabinet 47 and In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com