Liquid-liquid extraction mixer-settler and extraction method and application thereof

A mixing-settling tank and extraction technology, applied in the field of liquid-liquid extraction mixing-settling tank, can solve the problems of increasing the loss of solvent entrainment, increasing the number of filtration, etc., to prolong the time of clarification and phase separation, reduce the liquid storage capacity, and be easy to maintain and operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

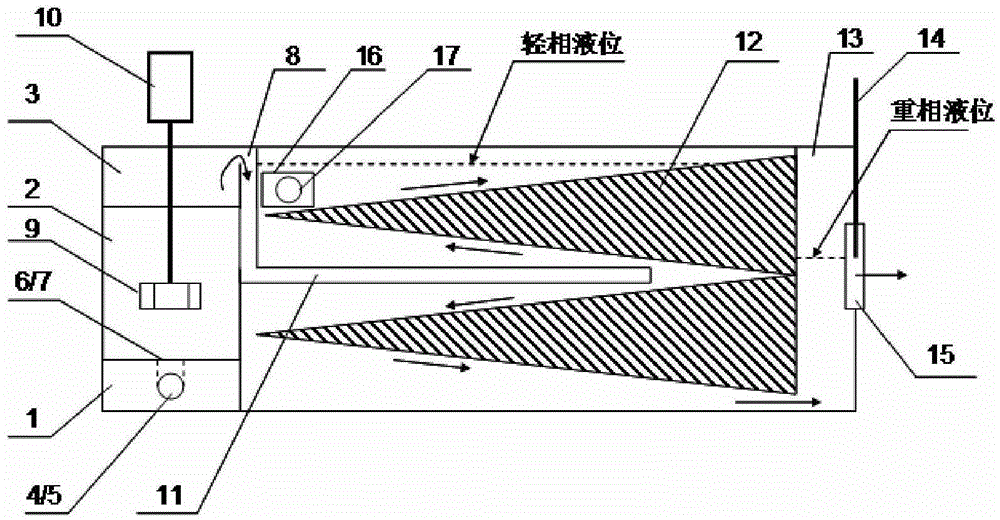

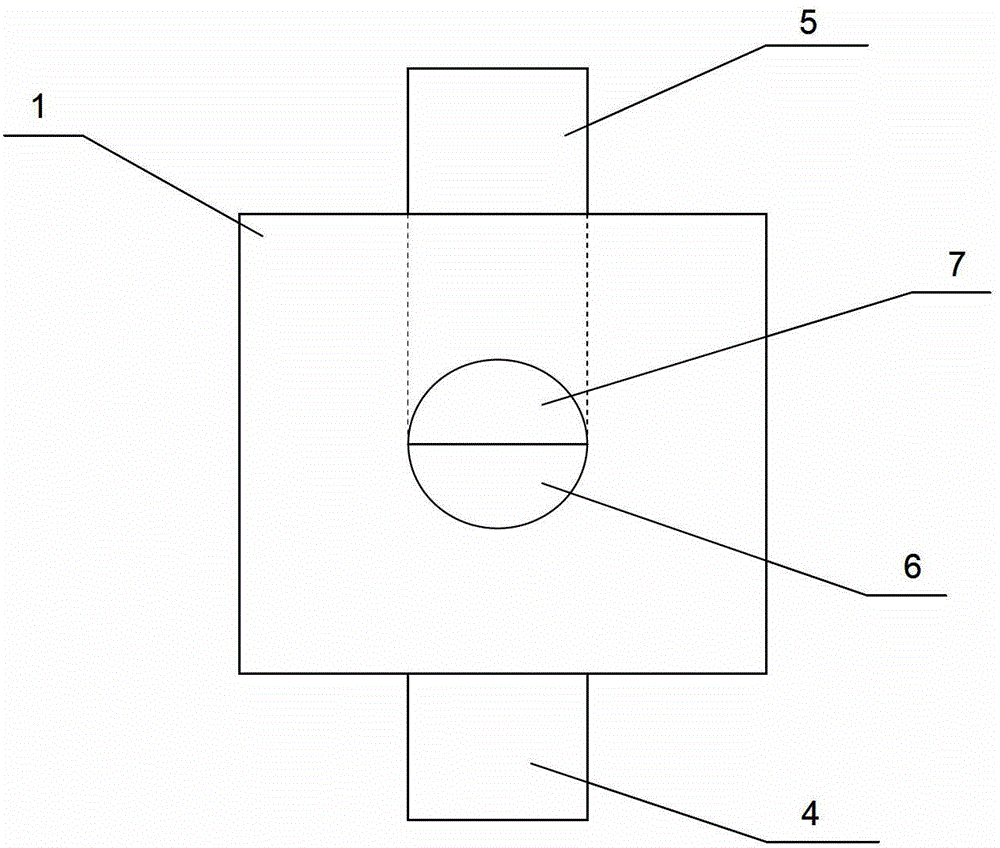

[0048] A liquid-liquid extraction mixing and settling tank, the mixing and settling tank includes a mixing chamber and a clarification chamber; the side of the clarification chamber near the mixing chamber is provided with a guide pipe 11, and the guide pipe 11 extends from the outlet of the mixing chamber to The end of the clarification chamber; in the clarification chamber, at least a wedge-shaped body 12 is fixed laterally above or below the draft tube 11 .

[0049] The liquid-liquid continuous extraction method is carried out through the mixing and settling tank. After the light and heavy phases are mixed in the mixing chamber, they flow into the draft pipe 11 from the outlet of the mixing chamber, and flow out from the end of the draft pipe 11 to the end of the clarification chamber. The side of 12 deflects to the front end of the clarification chamber, and after reaching the front end of the clarification chamber, it passes through the gap between the wedge body 12 and th...

Embodiment 2

[0051] like figure 1 As shown, a liquid-liquid extraction mixing and settling tank, the mixing and settling tank includes a mixing chamber and a clarification chamber. The side of the clarification chamber close to the mixing chamber is provided with an L-shaped draft pipe 11, and the L-shaped draft pipe 11 extends from the outlet of the mixing chamber to the end of the clarification chamber; the clarification chamber is above the L-shaped draft pipe 11 A wedge-shaped body 12 is fixedly arranged laterally at the bottom and below.

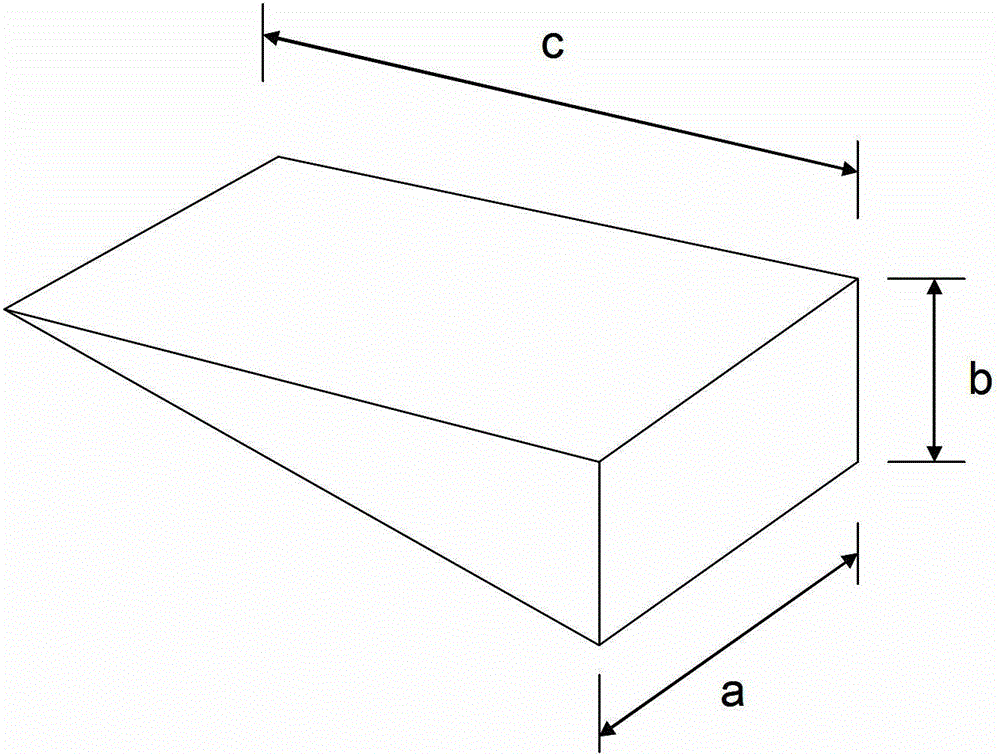

[0052] The bottom end of the wedge-shaped body 12 is fixed on the end side wall of the clarification chamber, and its top end is close to one end of the mixing chamber, leaving a gap with the side wall of the mixing chamber. The width a of the wedge-shaped body 12 is equal to the width of the clarification chamber, its vertical height b is half of the height of the clarification chamber, and its horizontal length c is equal to the length of the cla...

specific Embodiment 1

[0061]A liquid-liquid extraction mixing and settling tank, 6 stages connected in series, the length ratio of mixing chamber:clarifying chamber is 1:4. The clarification chamber is 600mm in length, 80mm in width and 170mm in height. The light phase of the extraction system is a kerosene solution of 2-ethylhexylphosphonic acid mono-2-ethylhexyl ester (referred to as P507), and the volume percentage of P507 is 30%. The heavy phase is an aqueous solution of sulfuric acid at pH=3.5 containing nickel and cobalt metal ions, in which nickel is 1.3g / L and cobalt is 0.8g / L. The light phase flow rate is 20L / h, and the heavy phase flow rate is 50L / h. The heavy phase sample is collected from the heavy phase liquid outlet 15 for analysis. The cobalt extraction rate is 98%, and the nickel extraction rate is 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com