Sewerage pretreatment method and denitrification anaerobic hydrolytic precipitation pool

A sewage pretreatment and anaerobic hydrolysis technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve high cost, poor treatment effect, and affect water quality and other issues, to achieve the effect of low cost, improved efficiency, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

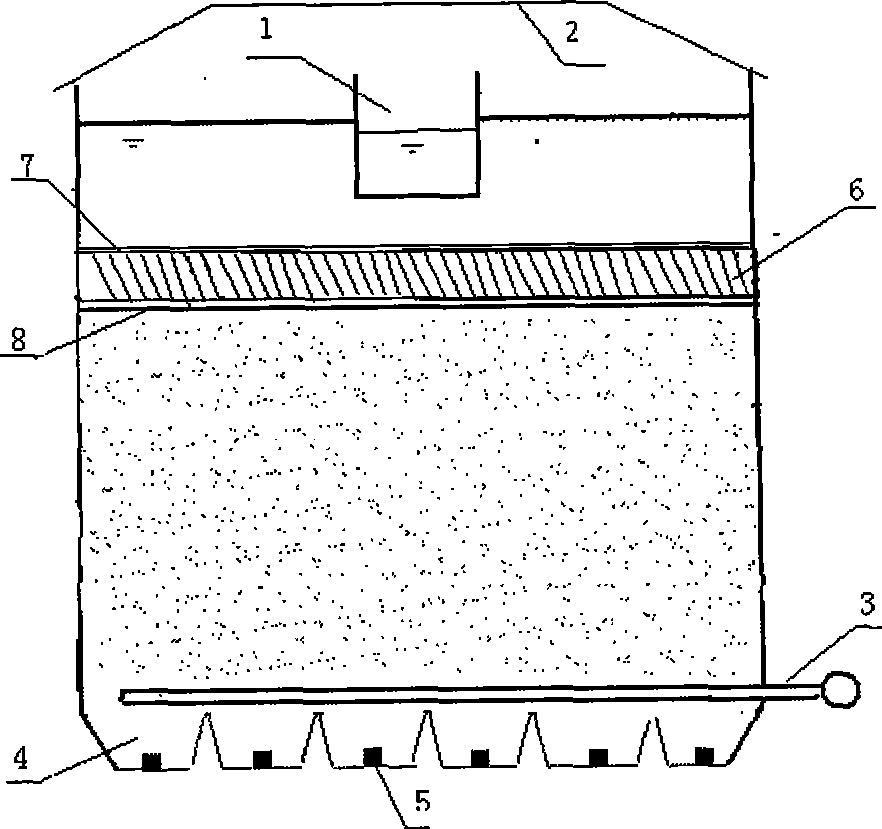

[0011] Specific Embodiment 1: In this embodiment, a sewage pretreatment method is realized by the following steps: 1. The sewage is discharged after being treated by the coarse grid, the medium grid, the drum type fine grid and the swirl grit chamber; 2. Steps One effluent enters the denitrification anaerobic hydrolysis sedimentation tank, and the maximum hydraulic load of the denitrification anaerobic hydrolysis sedimentation tank is controlled to be 4.5-6m 3 / m 2 h, the concentration of suspended sludge is 15-25g / L, the hydraulic retention time is 2.5-3h, and the ascending flow rate is 9-13m / h, that is, the pretreatment of sewage is realized.

[0012] The sewage pretreatment method in this embodiment has a removal rate of 30% to 50% for NH3-N in sewage, a removal rate for COD of 35% to 55%, and a removal rate for SS of 60% to 80%.

[0013] The pretreated sewage in this embodiment enters the biological aerated filter for advanced treatment. The discharge concentration of amm...

specific Embodiment approach 2

[0014] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the gap of the coarse grid in step 1 is 10cm; the water depth in front of the grid of the middle grid is 0.8m, the gap is 5cm, and the flow rate through the grid is 0.57m / s ; The pool volume of the cyclone grit chamber is 118m 3 , the surface load is 116.38m 3 / m 2 h, the hydraulic retention time is 40s. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0015] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the maximum hydraulic load of the denitrification anaerobic hydrolysis sedimentation tank in step two is 4.7 ~ 5.8m 3 / m 2 h, the sludge concentration is 17-23g / L, and the hydraulic retention time is 2.6-2.9h. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com