Comprehensive force field multithread gravity concentrator

A re-separator and force field technology, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of small processing capacity, poor classification accuracy, and influence on classification efficiency, and achieve high-efficiency separation and classification, and work Stable and reliable, high sorting precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

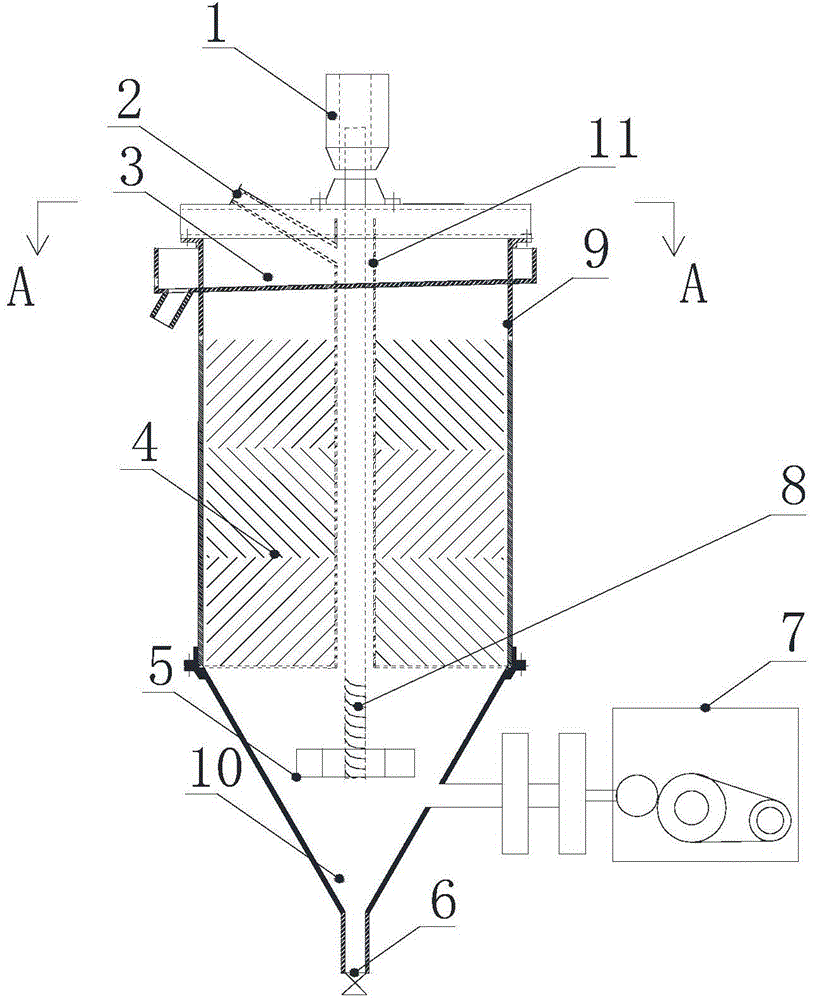

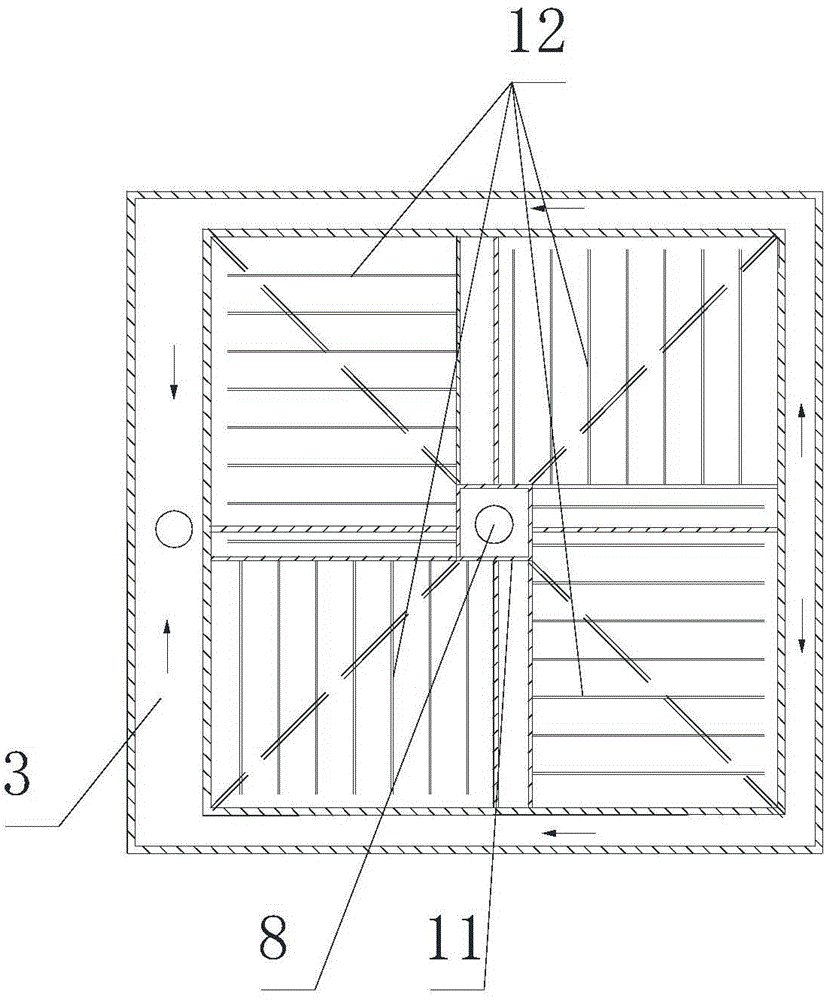

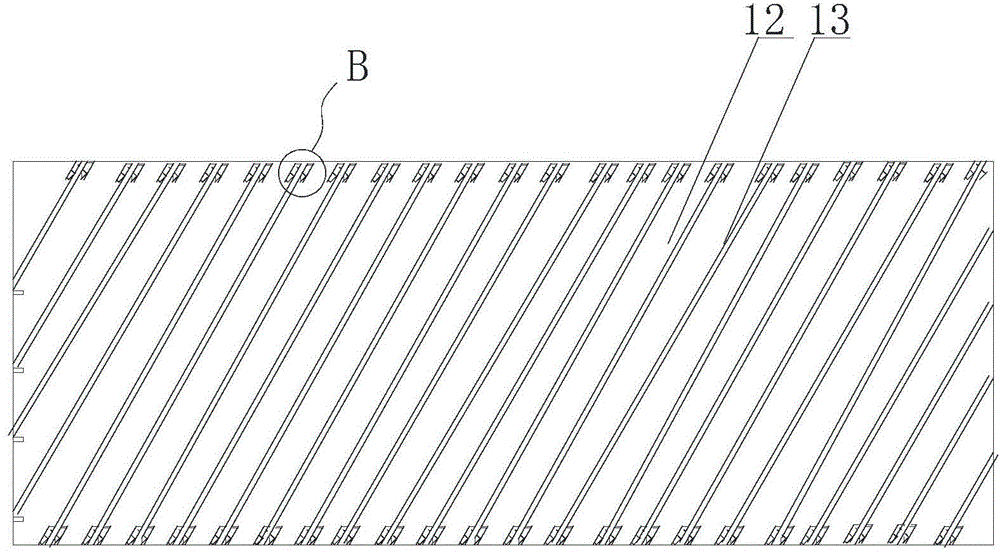

[0034] a kind of like figure 1 , figure 2 The multi-flow state re-separator with integrated force field of the present invention comprises a re-separator body 9, a driving device 1, a rotating device 5 and a pulsating device 7, and the re-separator body 9 is mainly composed of an upper column member (the present embodiment It is a regular quadrangular prism) and an inverted pyramid member at the bottom. The rotating device 5 and the pulsating device 7 are arranged on the bottom of the re-separator body 9, and the bottom of the re-separator body 9 forms a turbulent flow field and a pulsating force field together. The acting comprehensive force field settles and separates the area 10, and the integrated force field settles and separates the area 10 in the area surrounded by the lower inverted pyramidal body members. The top central area of the re-separator body 9 is provided with a feed port 2, and the feed port 2 communicates with the lower comprehensive force field sedimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com