Horizontal spiral automatic discharge type sedimentation centrifuge with thorough separation effect

A decanter centrifuge, horizontal screw technology, applied in centrifuges with rotating drums, centrifuges, etc., can solve the problems of low speed, affecting the separation effect, liquid turbulence, etc., to suppress air bubbles and improve separation. effect, liquid phase clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

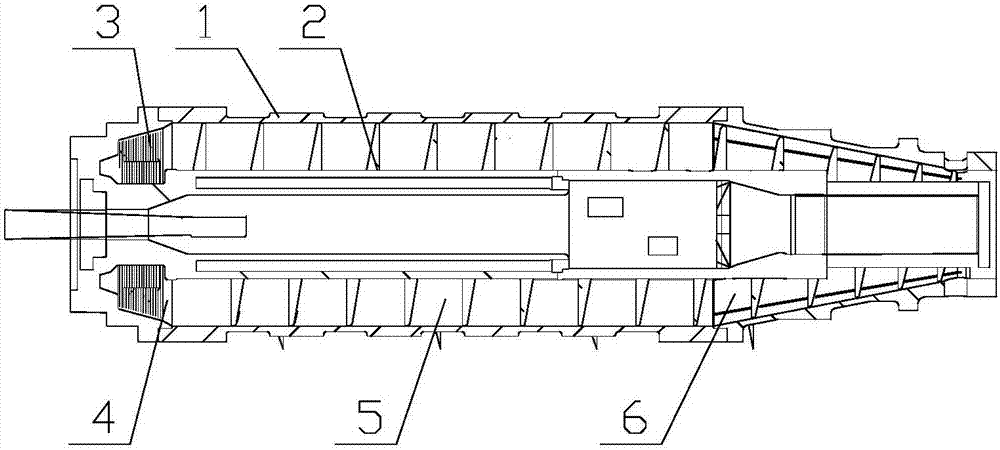

[0013] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a completely separated horizontal spiral automatic discharge sedimentation centrifuge proposed by the present invention.

[0014] refer to figure 1 , a completely separated horizontal spiral automatic unloading sedimentation centrifuge proposed by the present invention, comprising: a drum 1, a screw pushing barrel 2, a first motor, and a second motor;

[0015] The drum 1 is arranged horizontally. One end of the drum 1 is provided with a feed port and a liquid outlet, and the other end is provided with a discharge port. The inside of the drum 1 is provided with an accommodation chamber extending from the end of the feed port to the end of the discharge port;

[0016] The screw pusher barrel 2 is located in the storage chamber and is arranged along the direction from the feed port to the discharge port. The outer circumference of the screw pusher barrel 2 is provided with helical blades and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com