Clear liquid disturbanceless spiral discharging settling centrifugal machine

A settling centrifuge and screw unloading technology, applied in centrifuges, centrifuges with rotating drums, etc., can solve the problems of limited application range, achieve a wide range, improve the separation capacity of a single machine, and increase the settling area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

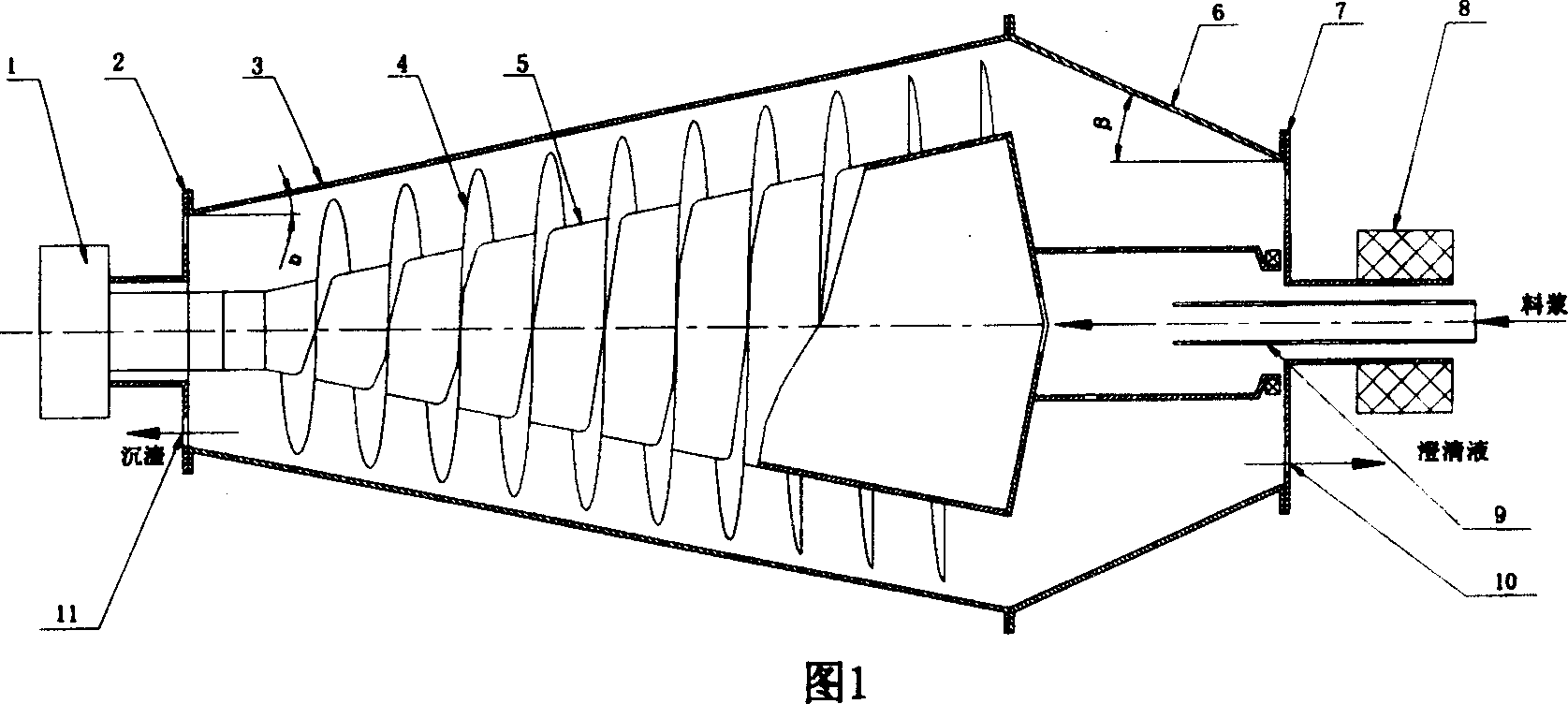

[0021] The structure is shown in Figure 1. The drum is composed of a spiral slag discharge section 3 and a clarified liquid overflow section 6. Both the spiral slag discharge section and the clarified liquid overflow section have a conical structure. The angle α is 10°, and the half-cone angle β of the cone in the clarified liquid overflow section is 40°. The drum is placed on the frame and driven by the motor through the belt pulley 8 transmission mechanism. The screw conveyor located in the drum, the part corresponding to the spiral slag discharge section of the drum, the spiral blade 4 and the cylinder body 5 where the blade is installed are basically the same as the cone cylinder half-cone angle α of the spiral slag discharge section of the drum conical structure. The part of the cylinder of the screw conveyor corresponding to the clarified liquid overflow section 6 of the bowl has a cylindrical structure, and no helical blade is arranged on it; the differential 1 is arran...

Embodiment 2

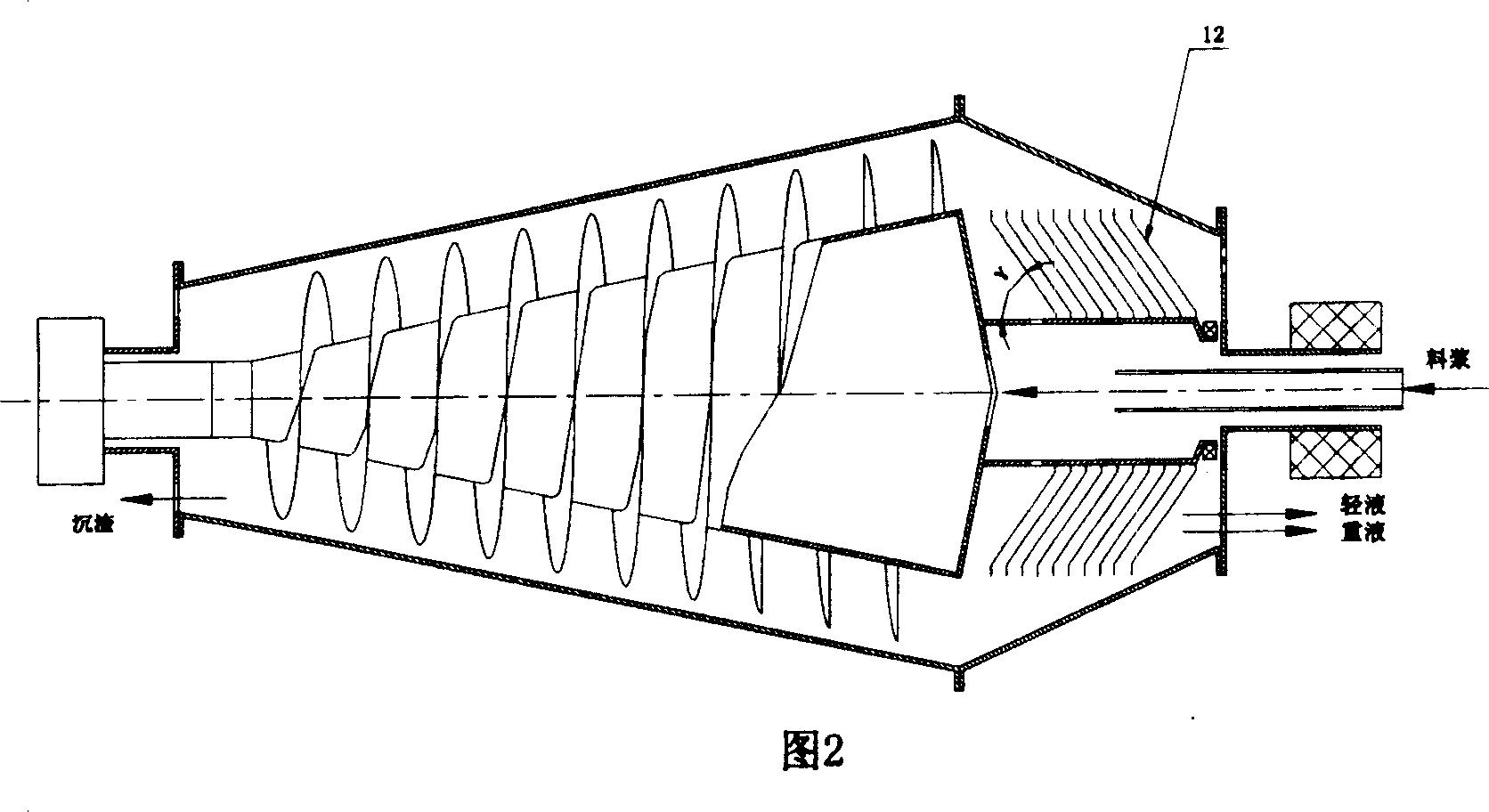

[0024] The specific structure is shown in Figure 2. The other structures of this embodiment are the same as those of Embodiment 1, except that a group of discs 12 that increase the settling area are arranged in the clarified liquid overflow section of the drum, and the discs are arranged on the barrel of the screw conveyor. . The direction of the half-cone angle γ of the disc is the same as that of the cone in the clarified liquid overflow section of the bowl.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com