Anti-blockage disk system

An anti-clogging and disc technology, applied to centrifuges with rotating drums, centrifuges, etc., can solve the problems of short service life, frequent cleaning, and easy blockage of separation channels, etc., to prolong the service life of the machine and improve Settling velocity, effect of lowering settling height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

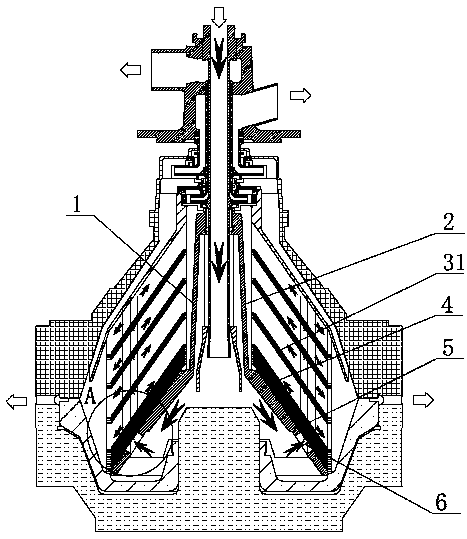

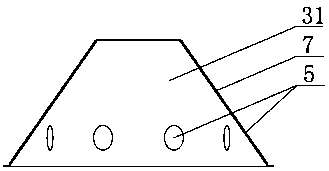

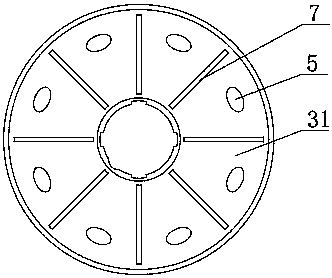

[0025] like Figure 5 As shown, a disc support 1 is provided on the outer periphery of the feed pipe in the drum, and the disc support 1 includes a disc support part 2 and a splitter chassis 4. The anti-clogging disc system is arranged on the outer periphery of the disc support 1. The disc system consists of It consists of a number of discs 3 stacked staggered on each other. The discs 3 are parallel to the diverter chassis 4 and are detachable cones. The discs 3 include an open disc 30 and a regular disc 31. A neutral hole is set on the regular disc 31. 5. Set up a liquid distribution channel 6 on the distribution chassis 4 corresponding to the neutral hole 5 . like Figure 6 , Figure 7 As shown, the opening disc 30 extends the neutral hole 5 on the disc 3 down to the outer edge of the disc 3 to form an inverted "U"-shaped opening 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com