A durable cutting machine

A durable, bar-breaking machine technology, used in ceramic molding machines, manufacturing tools, etc., can solve the problems of wire breakage, frequent replacement or maintenance of steel wires, etc., to achieve a flat section, increase normal working time, increase The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

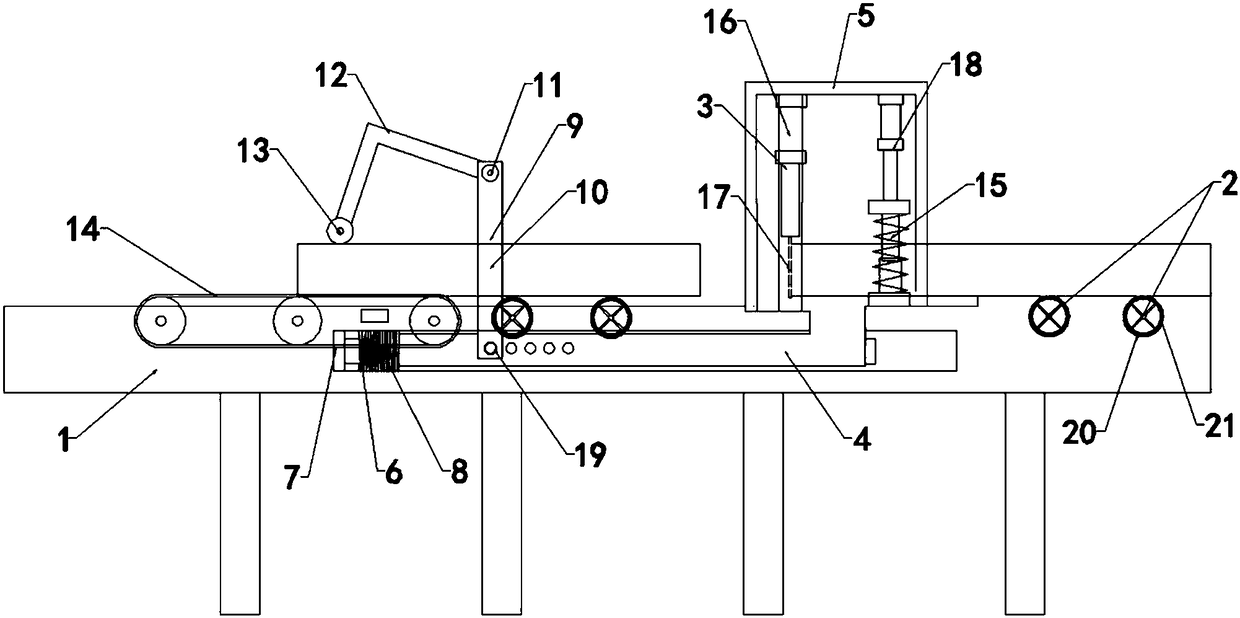

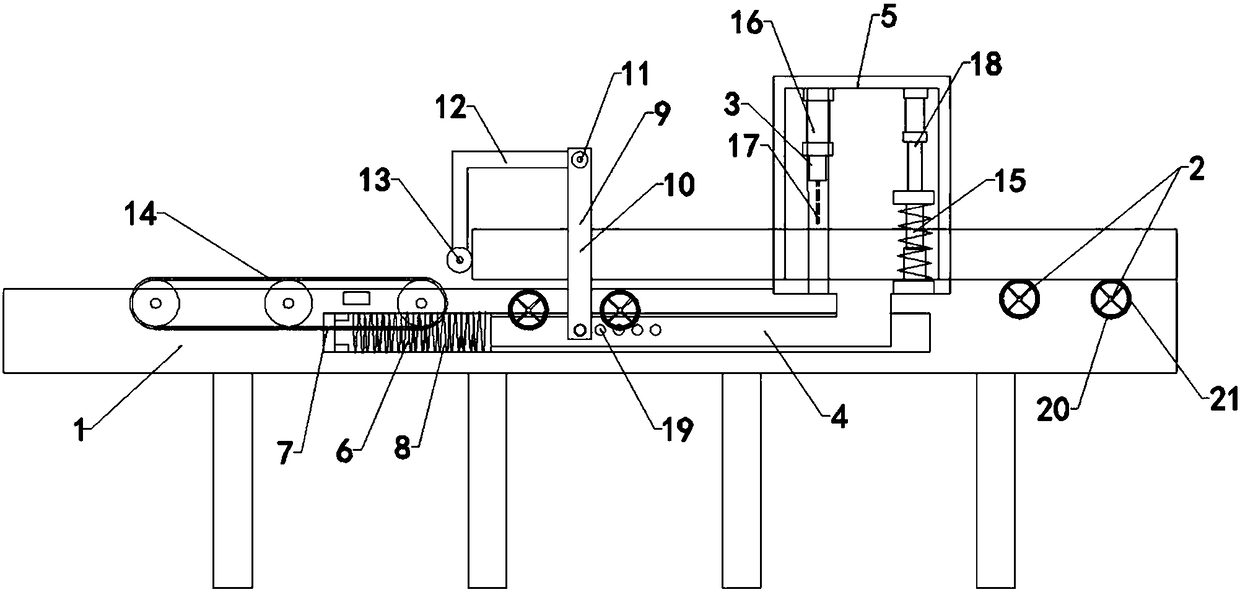

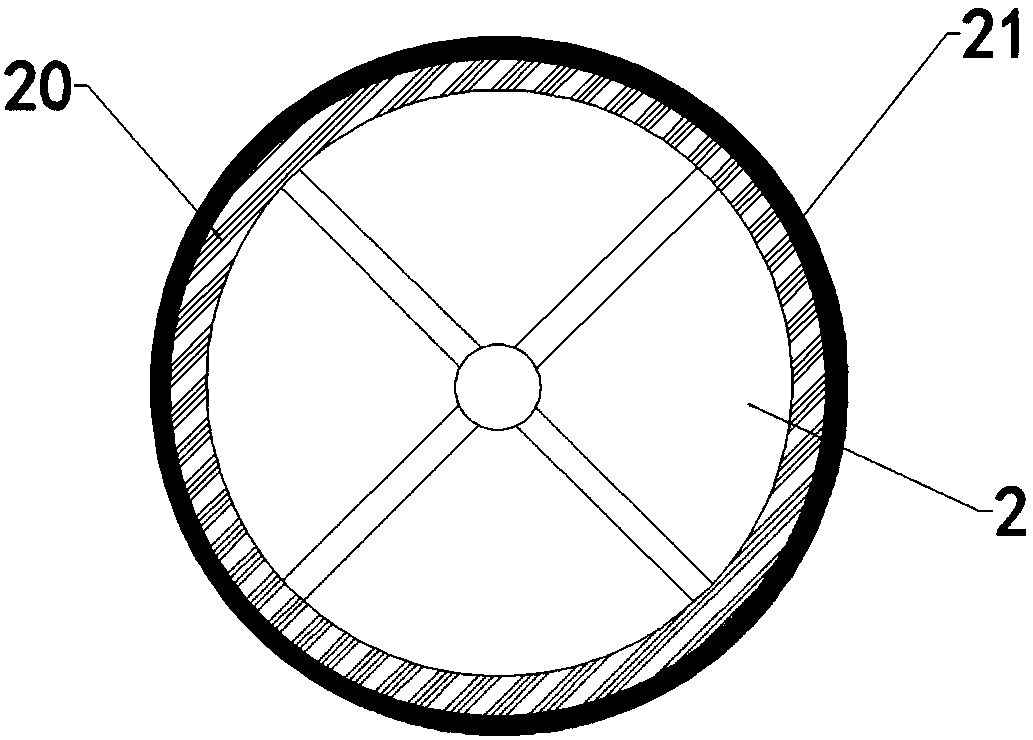

[0034] A durable sliver breaking machine, comprising a main frame 1, a conveying roller 2 arranged at the middle and right end of the main frame 1, a fast belt 14 arranged at the front end of the sliver breaking machine in the output direction, and a sliding belt that can slide along the length direction of the main frame 1. The rod 4 is characterized in that: the middle part of the sliding rod 4 is provided with a drive frame 9; the sliding rod 4 is provided with a reset device 6 at one end of the output direction of the slitting machine, and the other end is provided with a gantry 5; the gantry 5 The inside is respectively provided with a cutting device 3 and a compacting device 15; the cutting device 3 includes a cutting cylinder 16 arranged inside the gantry frame 5 and a sheet cutter 17 connected to the cutting cylinder 16, and the cutting cylinder 16 controls the sheet cutter 17 moves up and down; the compaction device 15 includes a compaction cylinder 18 fixed on the cro...

Embodiment 2

[0036] This embodiment is further improved on the basis of Embodiment 1. The drive frame 9 includes a support rod 10 fixedly connected to the sliding rods 4 on both sides, a rotating shaft 11 arranged between the two supporting rods 10, and a movable shaft that can rotate along the rotating shaft 11. Door 12; the movable door 12 is made up of a right-angle steel plate and a roller 13 arranged on the top of the right-angle steel plate. Since the driving frame 9 and the gantry frame 5 are respectively fixed on the sliding rod 4, the sliding rod 4 can move along the length of the main frame 1. direction sliding, so when the mud rod passes through the gantry 5 and travels to the position of the driving frame 9, the mud rod is in contact with the drum 13, thereby driving the driving frame 9, the sliding rod 4 and the gantry 5 to move forward together, when the mud rod and the gantry When the frame 5 speeds are consistent, the cutting device 3 on the portal frame 5 cuts off the mud r...

Embodiment 3

[0038] This embodiment is further improved based on Embodiment 2. The sliding rod 4 is horizontally provided with a plurality of limiting holes 19; . Since the horizontal distance between the cylinder 13 provided at the top of the driving frame 9 and the sheet cutter 17 is equal to the length of the mud bar that needs to be cut, so the position of the driving frame 9 can be adjusted by the limit hole 19 to obtain the required mud bar length.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com