Straight wall micro arch roadway and chamber U steel support technology

A steel bracket and arch technology, applied in underground chambers, tunnels, tunnel linings, etc., can solve the problem that the prestressed steel strand support cannot control the deformation of the surrounding rock, the auxiliary transportation of the roadway, the installation difficulty of the fully mechanized mining face, and the The problem of large amount of water sprayed in the anchor cable hole of the stress steel strand can achieve the effect of maintaining the integrity of the surrounding rock, reducing the degree of man-made damage and reducing the amount of water inflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, a kind of straight wall slightly arch roadway of the present invention and chamber U-shaped steel bracket technology will be further described in detail.

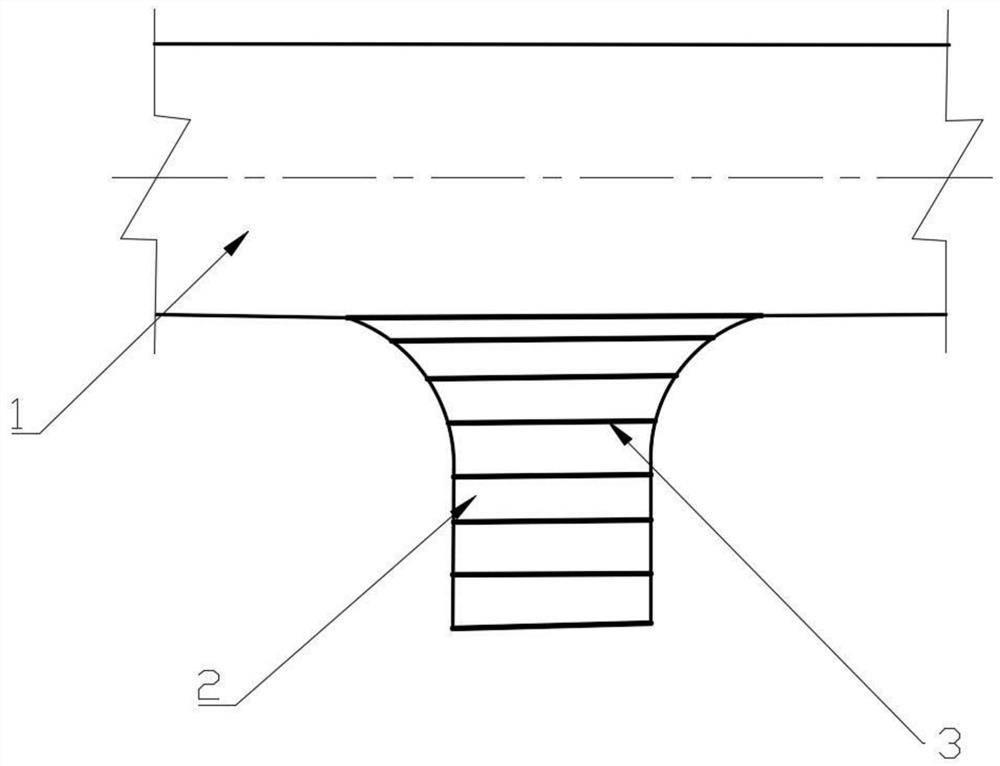

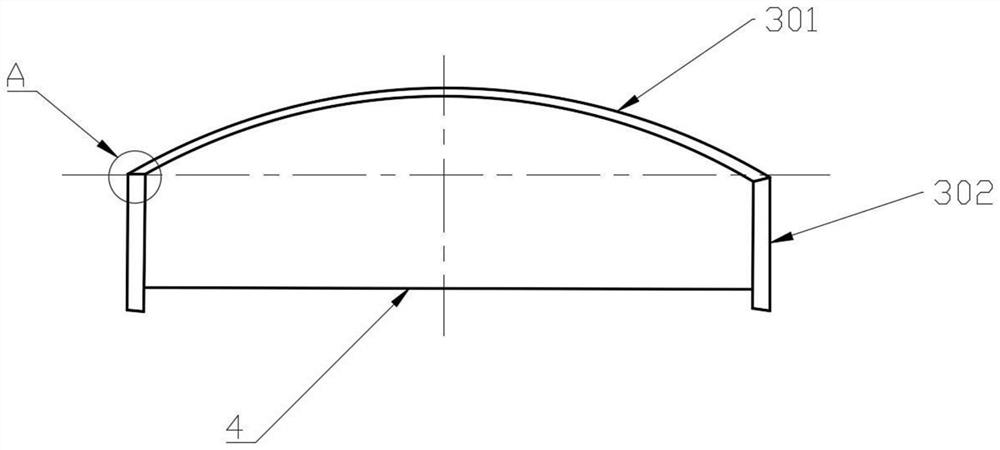

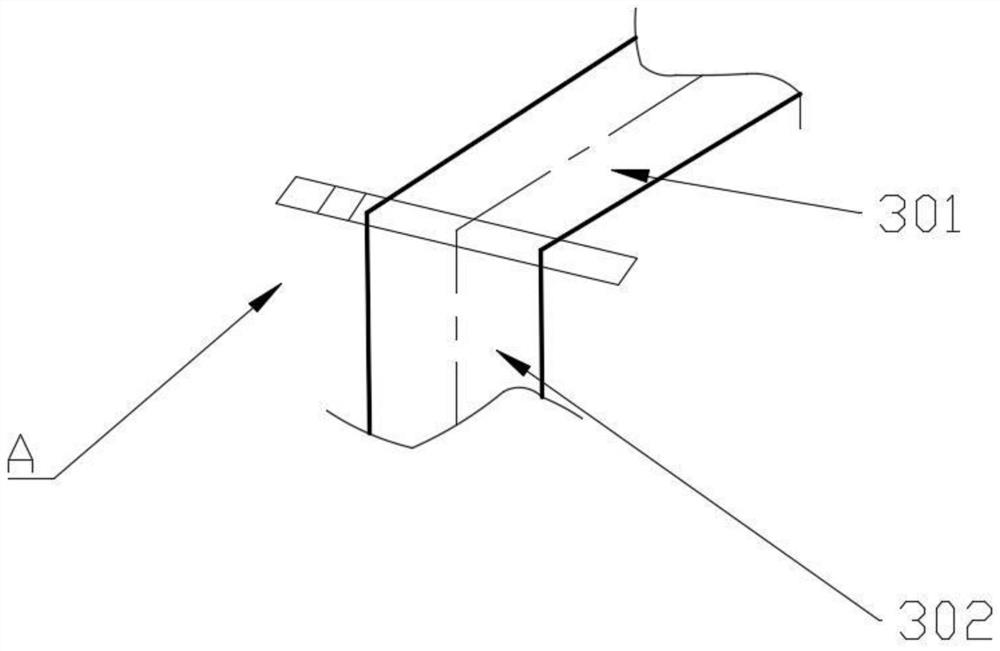

[0023] combined with Figure 1-Figure 7 , a U-shaped steel support technology for straight-wall micro-arched roadways and chambers, including a drainage roadway 1 in the mining area and a shunting chamber 2 connected to the drainage roadway. The bottom of the shunting chamber 2 is provided with a concrete floor 4. The inner wall of the shunting chamber 2 is fixed with a steel bracket 3 along the circumferential direction, and the steel bracket 3 is composed of an arch beam 301 supporting the roof of the shunting chamber 2 and columns 302 respectively fixed at the ends of the arch beam 301.

[0024] As a preferred implementation of this embodiment, the upper arch beam 301 of the steel bracket 3 at the opening of the shunting chamber 2 adopts a slightly arched U-shaped st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com