Granularity-controllable boehmite preparation method

A boehmite and particle size technology, applied in the field of boehmite preparation, can solve the problems of complex process, non-uniform morphology, wide particle size range, etc., and achieve the effects of high purity, uniform morphology and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Al(OH) 3 Mix with water to form a suspension with a concentration of 20-35% (mass fraction), adjust the pH to less than 5, treat it at a temperature of 170-200°C and a pressure of 1.5-1.7MPa for 24-40 hours, then filter and dry , and break up to obtain monodisperse boehmite, the monodisperse boehmite particle size is 0.1-0.8 micron.

Embodiment 2

[0023] Al(OH) 3 Mix with water to form a suspension with a concentration of 35-40% (mass fraction), adjust the pH to 5-7, treat at a temperature of 200-220°C and a pressure of 1.0-1.3MPa for 24-40 hours, then filter and dry , and break up to obtain monodisperse boehmite, the monodisperse boehmite particle size is 1-3 microns.

Embodiment 3

[0025] Al(OH) 3 Mix with water to form a suspension with a concentration of 40-60% (mass fraction), adjust the pH to 7-9, treat at a temperature of 220-240°C and a pressure of 1.0-1.3MPa for 24-40 hours, then filter and dry , and break up to obtain monodisperse boehmite, the monodisperse boehmite particle size is 3-10 microns.

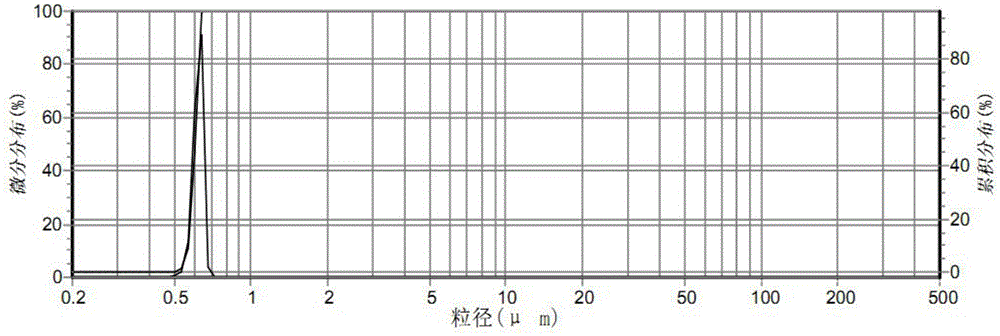

[0026] See attached picture, figure 1 It is the particle size distribution diagram of the 0.6 micron high-purity boehmite prepared by the present invention. It can be seen from the figure that the nano-scale boehmite prepared by the present invention has the characteristics of narrow and uniform particle size distribution.

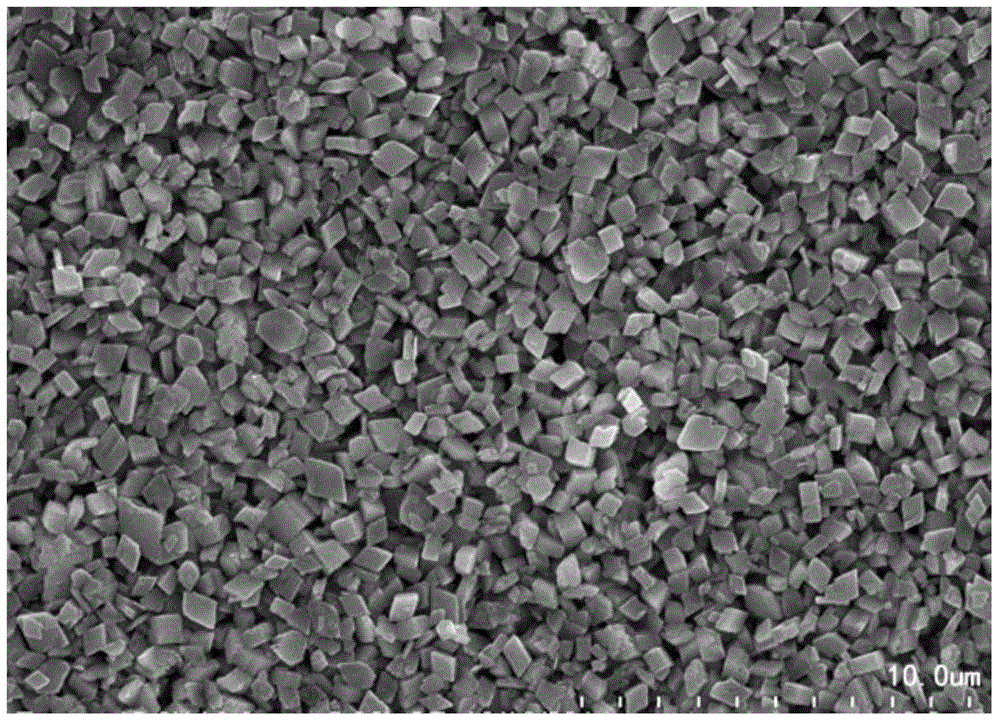

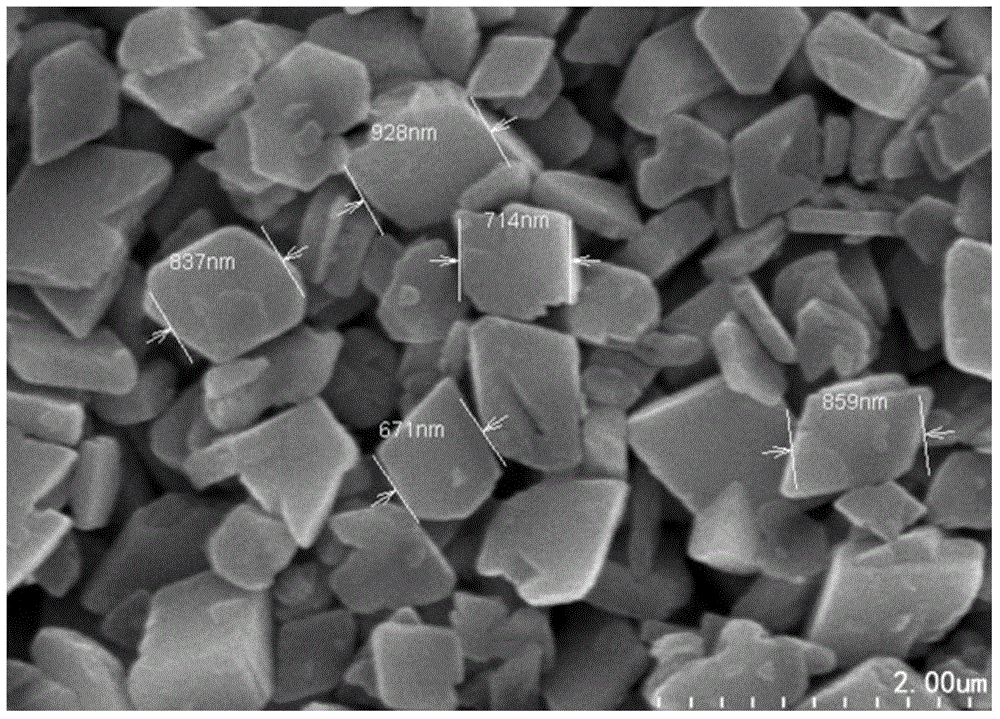

[0027] See attached picture, figure 2 and image 3 The scanning electron microscope (SEM) photo of the boehmite prepared for the present invention shows that the boehmite prepared by the present invention has a regular flaky structure, uniform particle size and good dispersion.

[0028] Table 1 Product parameters of boehmite o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com