Method for preparing bismuth titanate-barium titanate powder by hydrothermal method

A bismuth ferrite and barium titanate technology, which is applied in the field of preparation of bismuth ferrite-barium titanate functional ceramic powder, achieves the effects of high purity, uniform particle size distribution and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Using chemically pure KOH and deionized water to prepare a mineralizer solution with a concentration of 4mol / L; weighing and batching according to the stoichiometric ratio of bismuth ferrite-barium titanate: to analyze pure Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 9H 2 O, BaCl 2 and TiCl 4 As raw material, according to the chemical formula 0.1BiFeO 3 -0.9BaTiO 3 Batching, mixing, adding hydrochloric acid and deionized water dropwise, and completely dissolving the raw materials by magnetic stirring; adding the prepared mixed solution dropwise to the aforementioned KOH mineralizer solution at a speed of 2 drops / second, and continuing magnetic stirring for 1 hour, Then ultrasonically oscillate for 30 minutes to obtain a yellow-brown precursor solution; put the above-mentioned precursor solution into a stainless steel reaction kettle lined with polytetrachlorethylene, the filling degree is 80%, seal the reaction kettle, and place the reaction kettle at 210 Keep warm in an o...

Embodiment 2

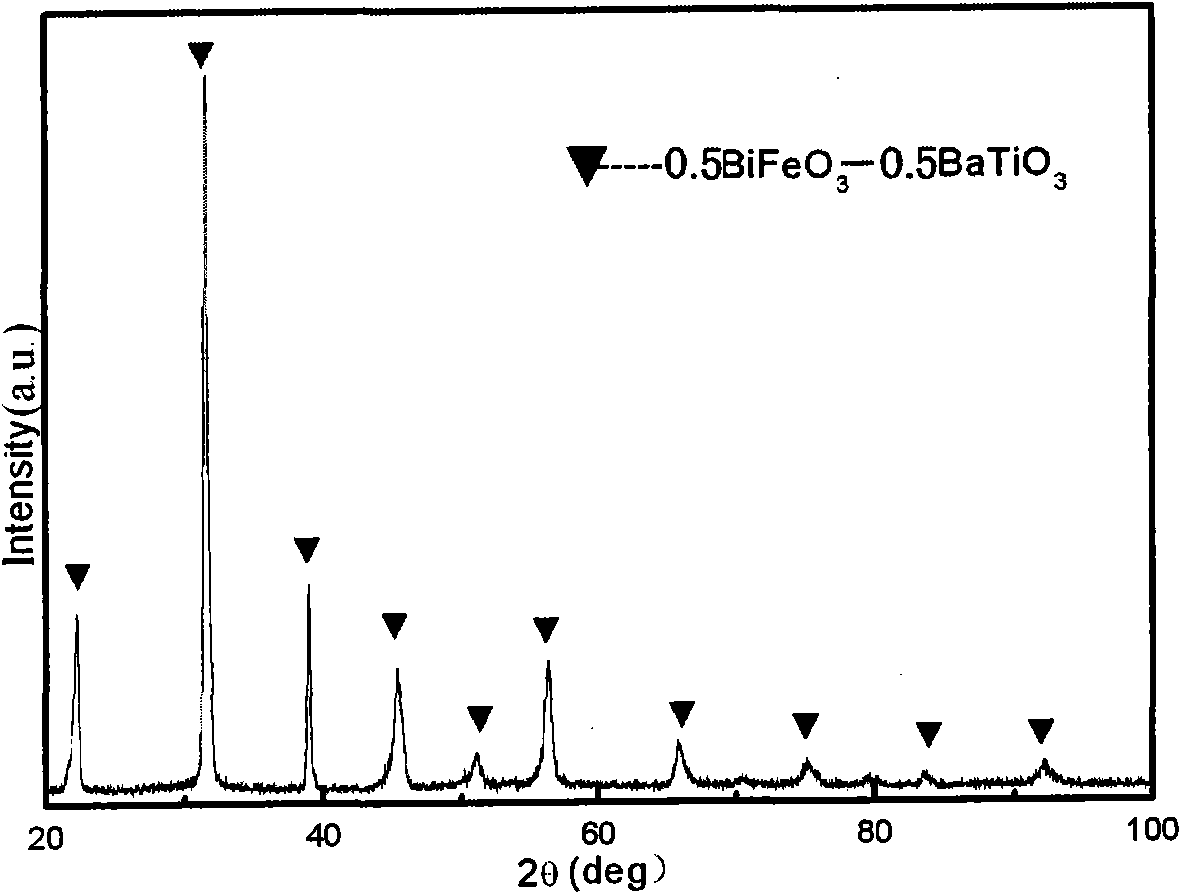

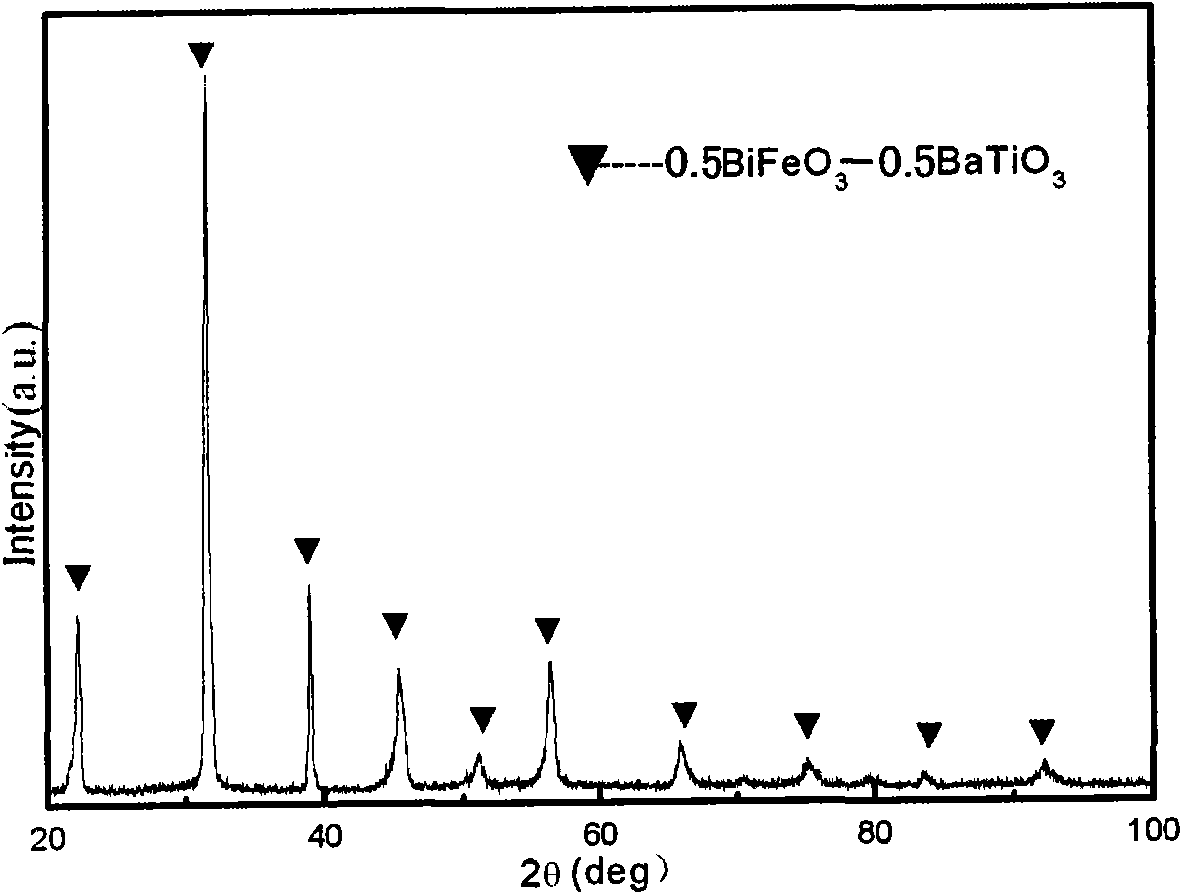

[0023] Using chemically pure KOH and deionized water to configure a mineralizer solution with a concentration of 10mol / L; weighing and batching according to the stoichiometric ratio of bismuth ferrite-barium titanate: to analyze pure Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 9H 2 O, BaCl 2 and TiCl 4 As raw material, according to the chemical formula 0.5BiFeO 3 -0.5BaTiO 3 Batching, mixing, adding hydrochloric acid and deionized water dropwise, and completely dissolving the raw materials by magnetic stirring; adding the prepared mixed solution dropwise to the aforementioned KOH mineralizer solution at a rate of 1 drop / second, and continuing magnetic stirring for 0.5 hours, Then ultrasonically vibrated for 10 minutes to obtain a yellow-brown precursor solution; put the above-mentioned precursor solution into a stainless steel reaction kettle lined with polytetrachlorethylene, and the filling degree is 60%, seal the reaction kettle, and place the reaction kettle at 190 Keep warm ...

Embodiment 3

[0025] Using chemically pure KOH and deionized water to configure a mineralizer solution with a concentration of 6mol / L; weighing and batching according to the stoichiometric ratio of bismuth ferrite-barium titanate: to analyze pure Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 9H 2 O, BaCl 2 and TiCl 4 As raw material, according to the chemical formula 0.9BiFeO 3 -0.1BaTiO 3 Batching, mixing, adding hydrochloric acid and deionized water dropwise, and completely dissolving the raw materials by magnetic stirring; adding the prepared mixed solution dropwise to the aforementioned KOH mineralizer solution at a rate of 1 drop / second, and continuing magnetic stirring for 0.5 hours, Then ultrasonically vibrate for 15 minutes to obtain a yellow-brown precursor solution; put the above-mentioned precursor solution into a stainless steel reactor lined with polytetrachlorethylene, and the filling degree is 70%, seal the reactor, and place the reactor at 200 Keep warm in an oven at ℃ for 36 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com