Nano-nano type Al2O3-base heterogeneous ceramic and its preparing method

A multi-phase ceramic and nano-type technology is applied in the preparation of high-performance structural ceramics with nano-nano-type composite structure, nano-nano-type Al2O3-based multi-phase ceramics and the field of preparation thereof, which can solve the problem of rapid grain growth and difficult to obtain. Dense nano-nano-type composite ceramics, grain size control, etc., to achieve uniform grain size distribution, short sintering time, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

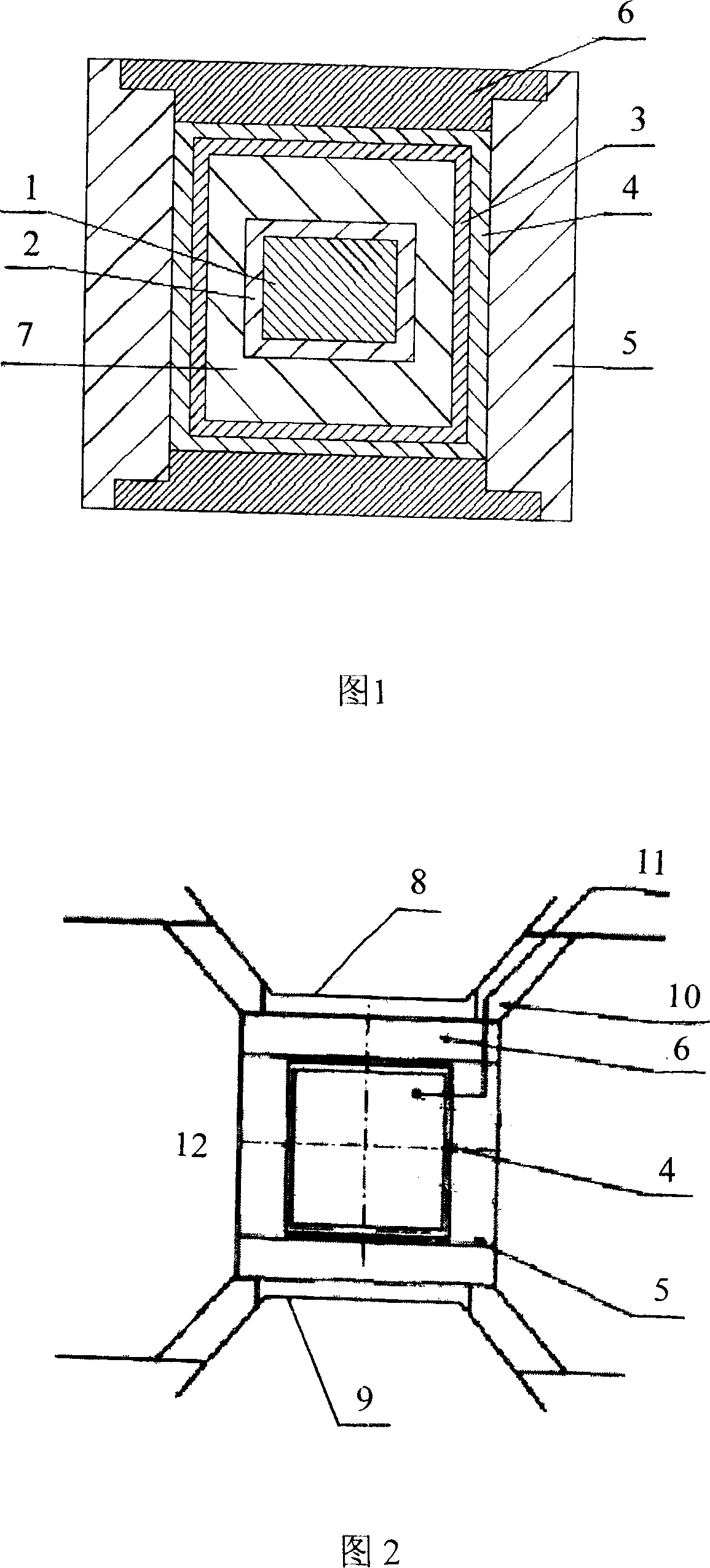

[0031] Embodiment 1: see accompanying drawing 1-3.

[0032] A kind of nano-nano type Al 2 o 3 A method for preparing a base composite phase ceramic, the preparation method comprising the following steps:

[0033] (1) Ingredients ball mill

[0034] Nano Al2 o 3 powder, nano-SiC powder according to 70Vol% Al 2 o 3 -30Vol% SiC volume percentage example After taking the ingredients, mix and place in a planetary ball mill, ball mill in absolute ethanol solvent at 400 rpm for 10 hours, then filter, dry at 60-120°C, pass through 60 Mesh sieve to obtain nanocomposite powder with evenly dispersed toughening and reinforcing phase;

[0035] (2) Molding

[0036] At room temperature and a pressure of 10MPa, the nanocomposite powder is pre-pressed into a Φ28.6×10mm disc with a steel mold, and then the pre-pressed disc is placed in a rubber elastic mold, under a pressure of 200MPa cold isostatic pressing into green body 1;

[0037] (3) Body heat treatment

[0038] Heat-treat the gr...

Embodiment 2

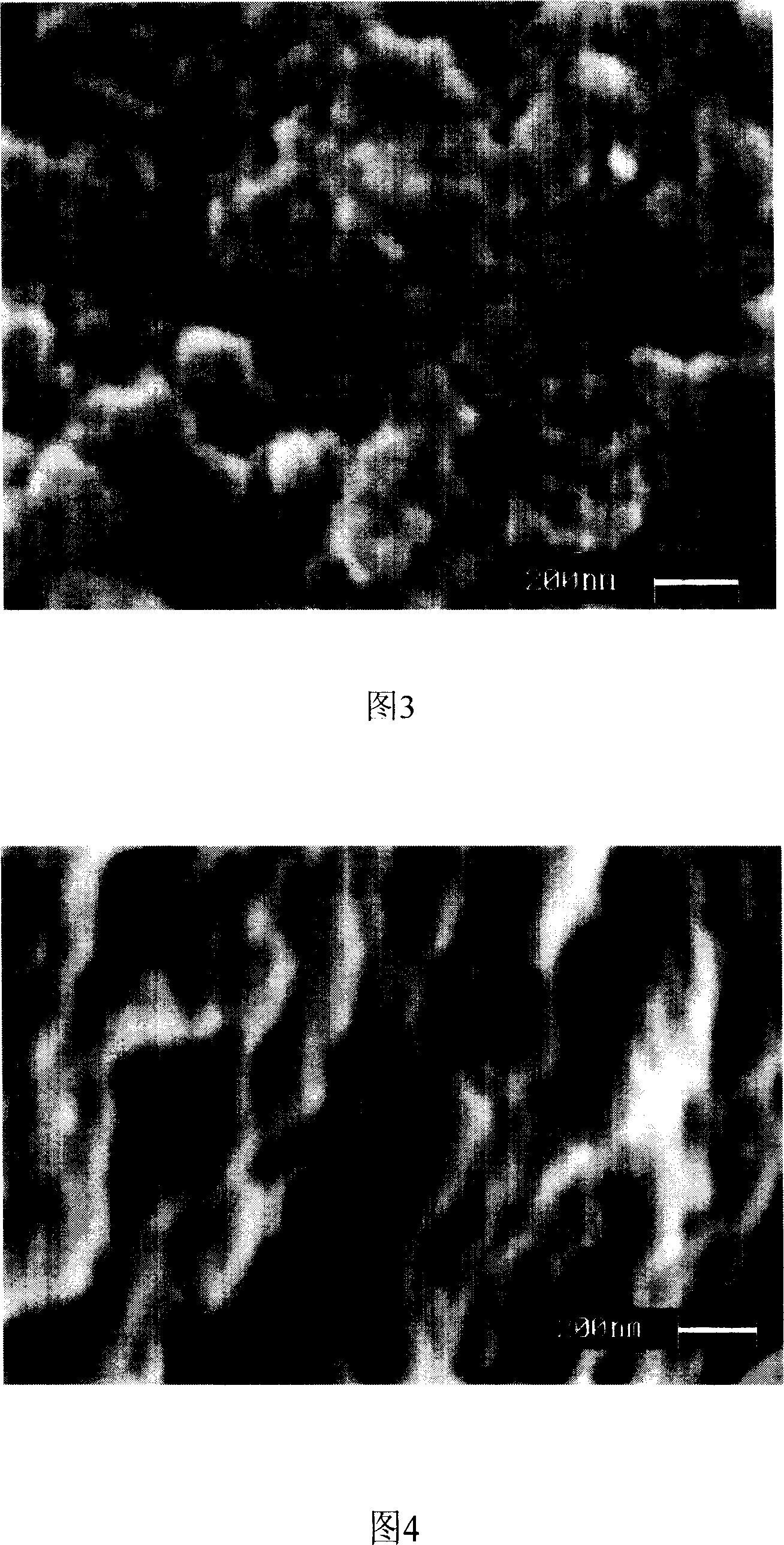

[0045] Embodiment 2: see accompanying drawing 1,2,4.

[0046] A kind of nano-nano type Al 2 o 3 A method for preparing a base composite phase ceramic, the preparation method comprising the following steps:

[0047] (1) Ingredients ball mill

[0048] Nano Al 2 o 3 powder, nano-SiC powder according to 95Vol% Al 2 o 3 -5Vol% SiC volume percentage example After taking the ingredients, mix and place in a planetary ball mill, ball mill in absolute ethanol solvent at 150 rpm for 24 hours, then filter, dry at 60-120°C, pass through 80 Mesh sieve to obtain nanocomposite powder with evenly dispersed toughening and reinforcing phase;

[0049] (2) Molding

[0050] At room temperature and a pressure of 5MPa, pre-press the nanocomposite powder into a Φ18×10mm disc with a steel mold, then put the pre-pressed disc into a rubber elastic mold, and cool it under a pressure of 250MPa. static pressure molding into green body 1;

[0051] (3) Body heat treatment

[0052] heat-treating the...

Embodiment 3

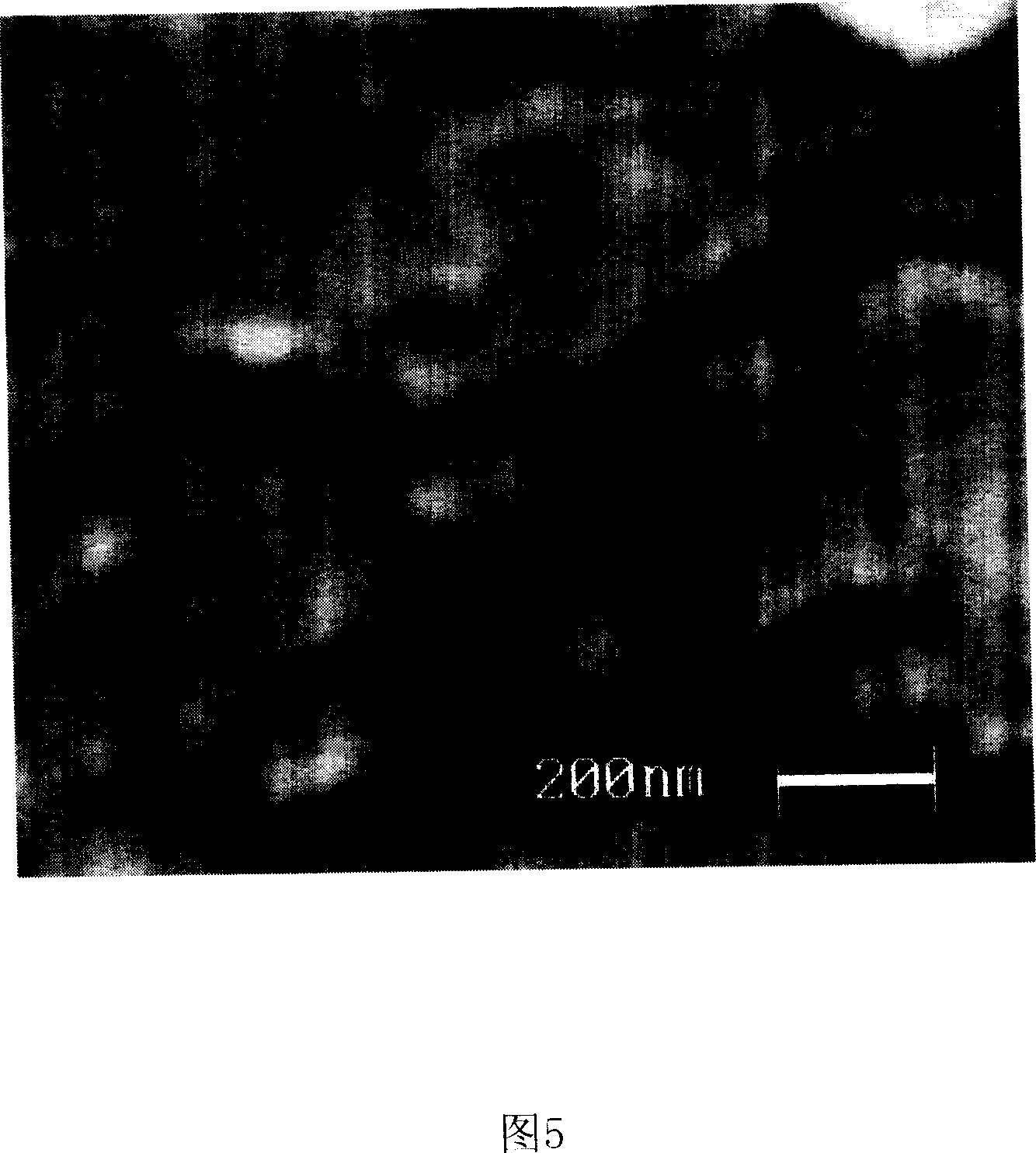

[0059] Embodiment 3: see accompanying drawing 1,2,5.

[0060] A kind of nano-nano type Al 2 o 3 A method for preparing a base composite phase ceramic, the preparation method comprising the following steps:

[0061] (1) Ingredients ball mill

[0062] Nano Al 2 o 3 powder, nano-SiC powder according to 80Vol% Al 2 o 3 -20Vol% SiC volume percentage example After taking the ingredients, mix and place in a planetary ball mill, ball mill in absolute ethanol solvent at 400 rpm for 48 hours, then filter, dry at 60-120°C, and pass through 20 Mesh sieve to obtain nanocomposite powder with evenly dispersed toughening and reinforcing phase;

[0063] (2) Molding

[0064] At room temperature and a pressure of 5MPa, the nanocomposite powder is pre-pressed into a Φ28.6×10mm disc with a steel mold, and then the pre-pressed disc is placed in a rubber elastic mold, under a pressure of 250MPa cold isostatic pressing into green body 1;

[0065] (3) Body heat treatment

[0066] heat-treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com