Generation method and device of qualified crystal grain distribution pattern

A distribution map and grain technology, applied in the direction of measuring devices, instruments, semiconductor/solid-state device testing/measurement, etc., can solve problems such as errors, inaccurate qualified grain distribution maps, and affecting wafer shipment efficiency, etc., to achieve reduction The effect of manual operation, improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

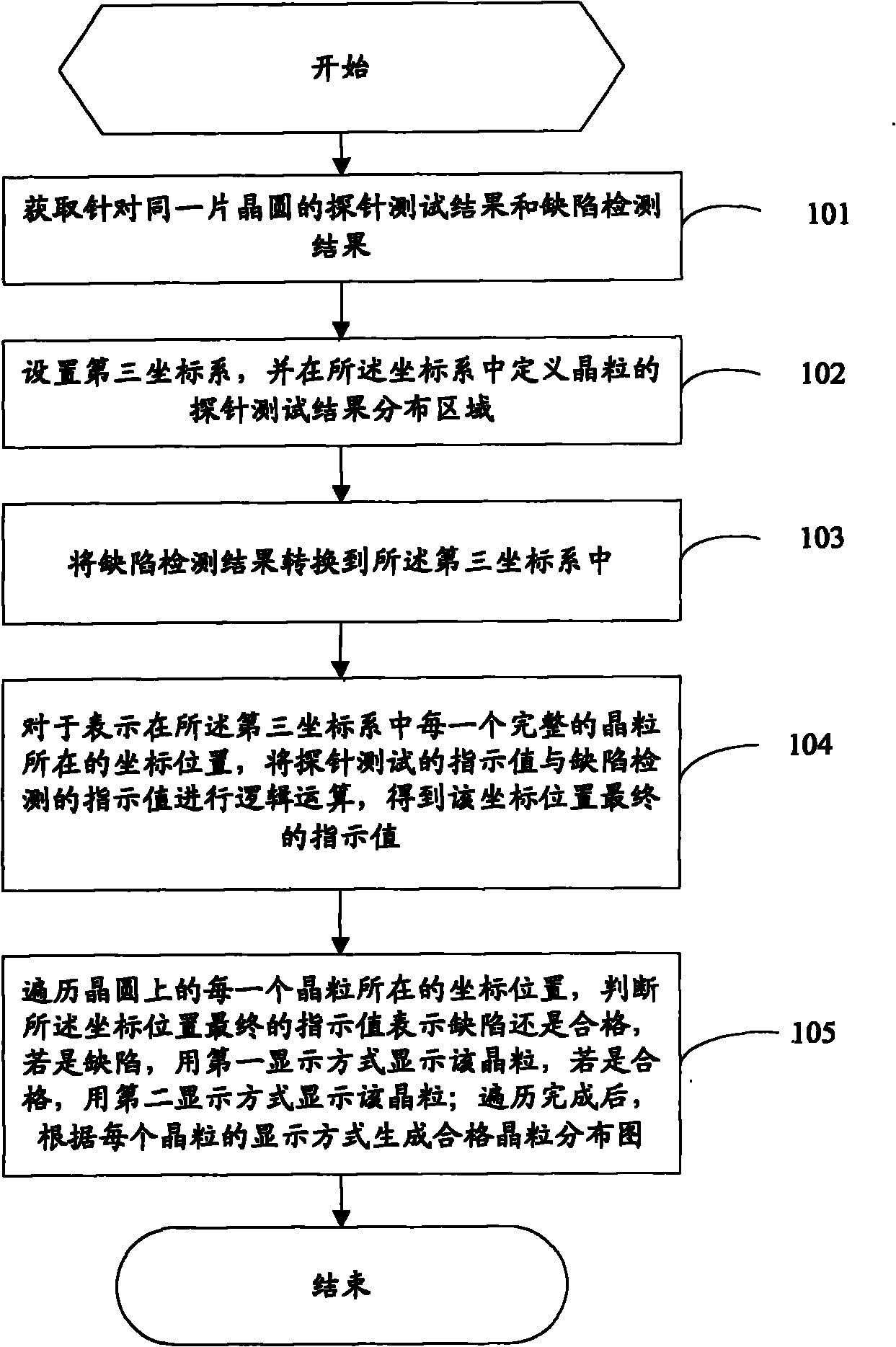

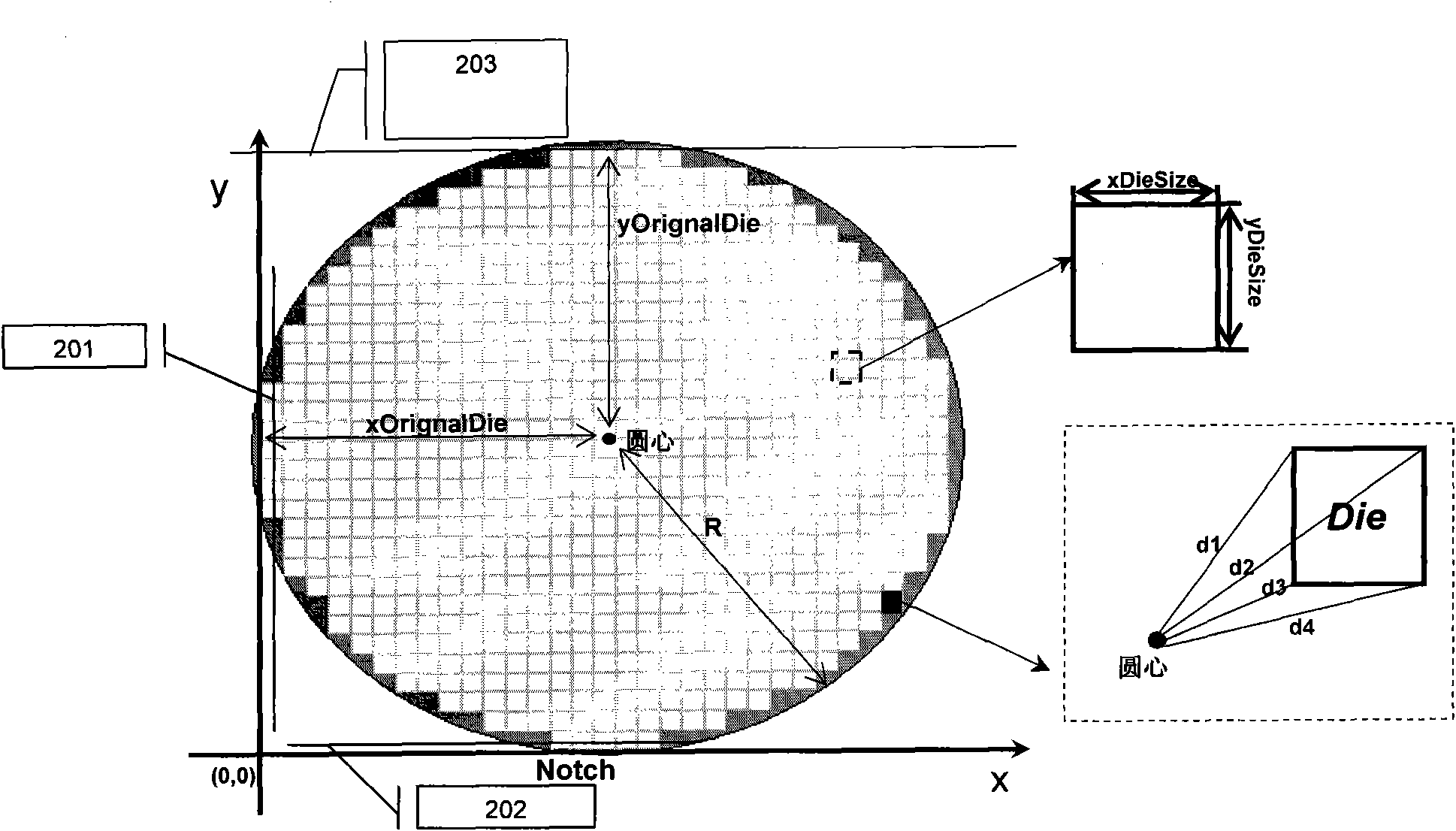

[0037] figure 1 Shown is the generation process of the qualified grain distribution diagram proposed by the embodiment of the present invention, including the following steps:

[0038] Step 101: Obtain probe test results and defect detection results for the same wafer.

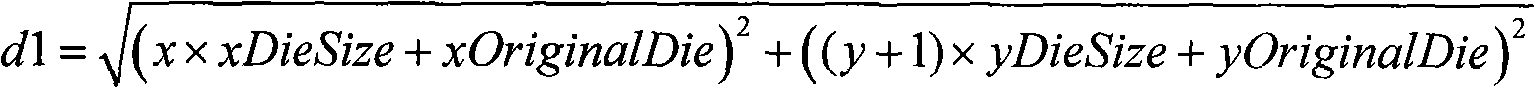

[0039] The probe test results include N1 sets of data, and N1 is the total number of dies on the wafer subjected to probe test. Each set of data includes an x coordinate value and a y coordinate value, which are used to indicate the position of the crystal grain corresponding to the set of data on the wafer; the data also includes an indicator value (flag), which is used to indicate the corresponding Whether the die is qualified, for example, a logic 1 is used to indicate that it is not qualified, and a logic 0 is used to indicate that it is qualified. The defect detection result includes N2 sets of data, and N2 is the total number of crystal grains for which defect detection is performed on the wafer. Ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com