Direct synthesis method of nanometer oxide powder

A technology of nano-scale oxides and nano-powders, which is applied in the preparation of ferrous oxides, titanium oxide/hydroxides, oxides/hydroxides, etc., can solve the problem of high decomposition temperature and particle size of nano-powders Large size, expensive equipment, etc., to achieve the effect of uniform particle size, narrow particle distribution, and avoid grain growth and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

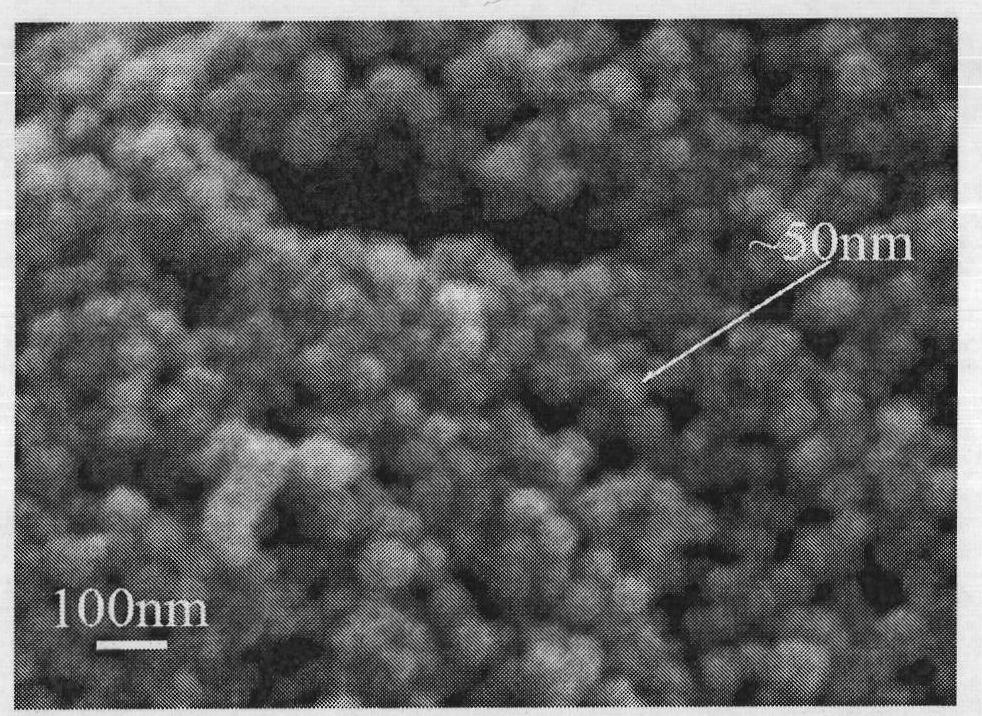

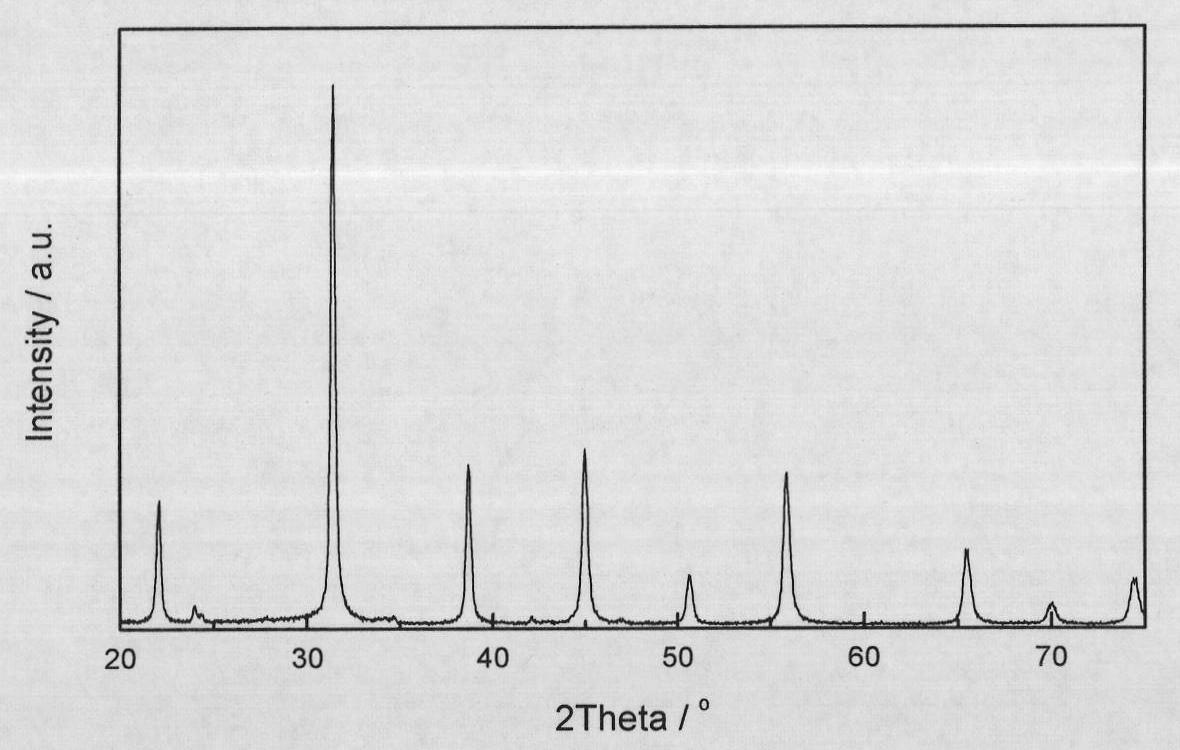

[0029] Disperse and dissolve 68 g of tetrabutyl titanate into 500 ml of absolute ethanol by stirring to obtain liquid A. 63.1 g of Ba(OH) 2 ·8H 2 O was dispersed and dissolved in 500 ml of 60°C water by stirring to obtain liquid B. Slowly add 2 grams of dodecyl alcohol and liquid A into liquid B while stirring. After the dropwise addition was completed, the solid and liquid were separated. Dry the solid part at 20-100°C to directly obtain BaTiO 3 nanoparticles. XRD shows that the obtained powder is BaTiO with perovskite structure 3 Micronized. SEM showed that the micropowder was nearly spherical crystalline particles with a uniform size and a particle diameter of ~50 nm.

Embodiment 2

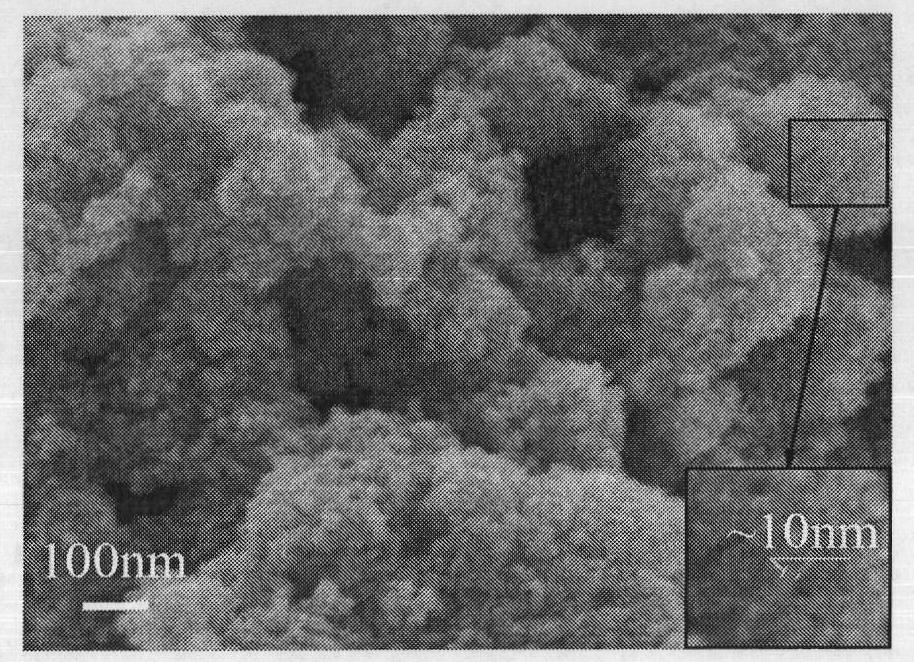

[0031] Dispersed and dissolved 34 g of tetrabutyl titanate into 50 ml of n-butanol to obtain liquid A. 31.6 g Ba(OH) 2 ·8H 2 O was added to a ball mill jar with a volume of 250 milliliters, and 100 milliliters of n-butanol was used as a dispersant, and ball milled at a speed of 200 rpm for 4 hours to obtain liquid B. Add liquid A into the ball mill tank containing liquid B, and add 1 gram of dodecyl alcohol as a surfactant at the same time, and ball mill at a speed of 200 rpm for 4 hours. After ball milling, ventilate and dry at room temperature to directly obtain BaTiO 3 nanoparticles. XRD shows that the obtained powder is BaTiO with perovskite structure 3 Micronized. SEM showed that the micropowder was nearly spherical crystalline particles with a uniform size and a particle diameter of ~10 nm.

Embodiment 3

[0033] 29.1 g Co(NO 3 ) 2 ·6H 2 O and 80.8 g Fe(NO 3 ) 3 9H 2 O was dispersed in 100 ml of absolute ethanol to obtain liquid A. Add 32 grams of NaOH into a ball milling jar with a capacity of 250 milliliters, use 100 milliliters of absolute ethanol dispersant, and ball mill at a speed of 200 rpm for 4 hours to obtain liquid B. Add liquid A into the ball mill tank containing liquid B, and add 1 gram of dodecyl alcohol as a surfactant at the same time, and ball mill at a speed of 200 rpm for 4 hours. After ball milling, wash repeatedly with water for 5 times, and then dry at 20-100°C to directly obtain CoFe 2 o 4 nanoparticles. XRD shows that the obtained powder is CoFe with cubic structure 2 o 4 Micronized. SEM showed that the micropowder was nearly spherical crystalline particles with a uniform size and a particle diameter of ~5 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com