Boiling bed coal tar hydrotreating-hydrocracking composite catalyst and preparation method thereof

A composite catalyst, hydrotreating technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, molecular sieve catalysts, etc. Harsh reaction conditions and other problems, to achieve the effect of reducing processing burden, improving mechanical strength and wear resistance, and moderate cracking activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

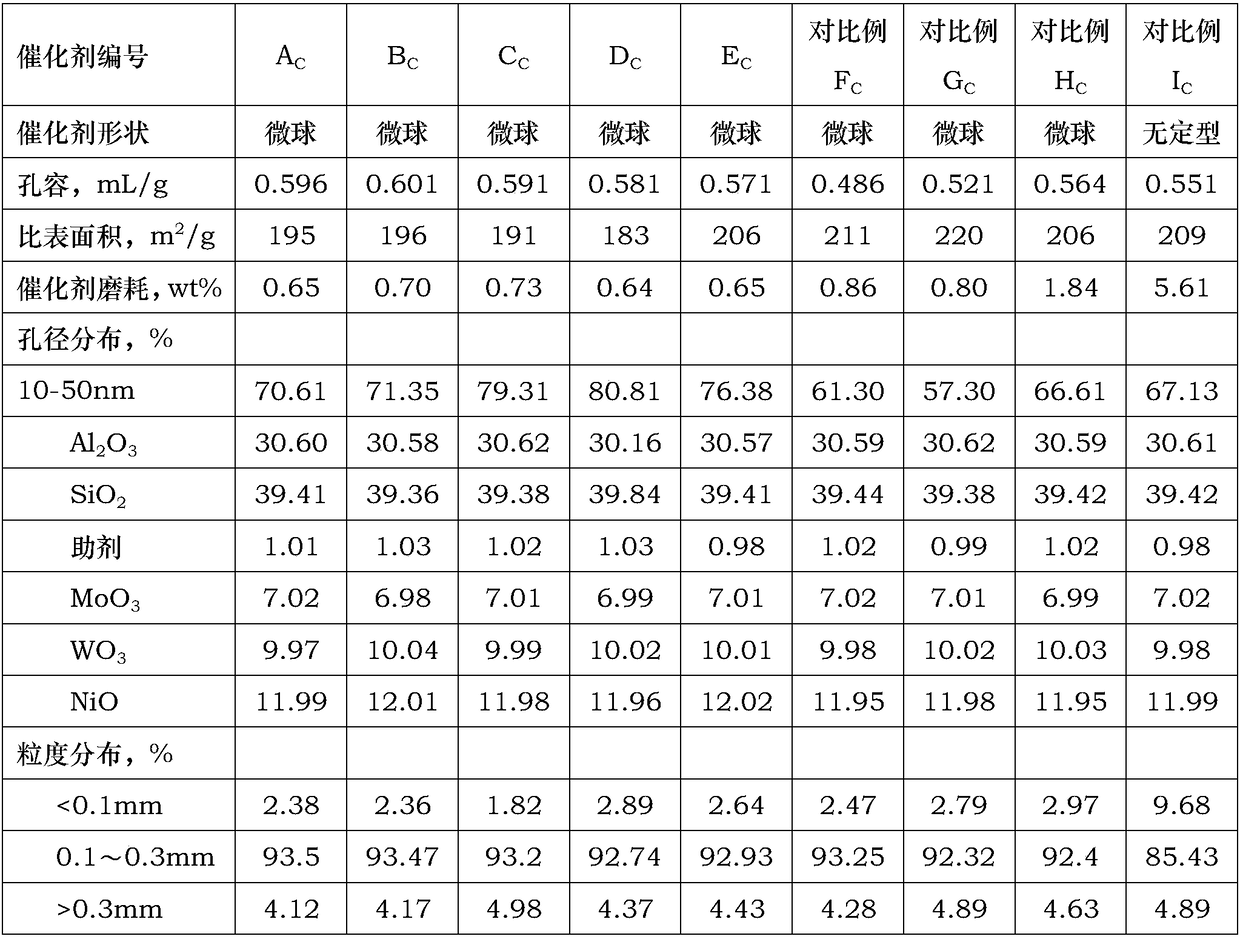

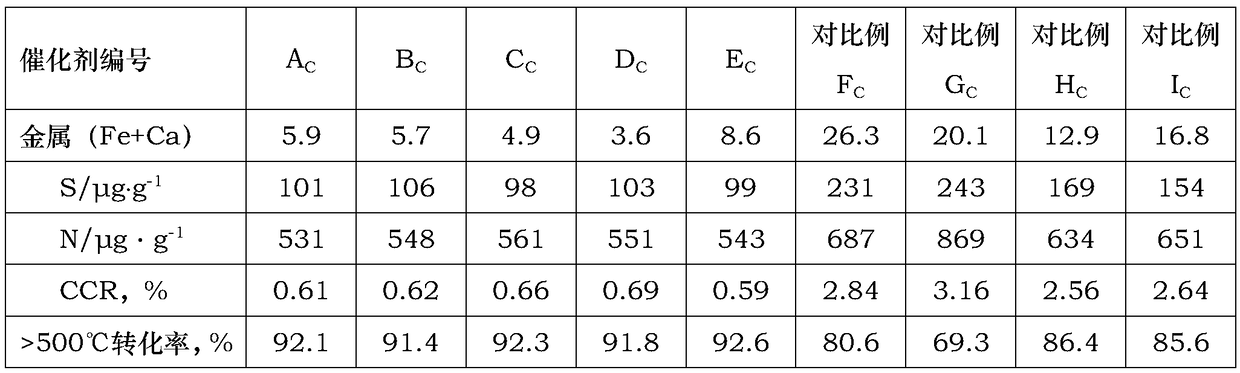

Examples

Embodiment 1

[0041] Add 100 g of water glass with a silicon oxide content of 35% in the preparation tank, start the stirring device, and then slowly add a 62% nitric acid solution to make the pH of the acidified water glass solution 2.5, mix well and add to the preparation tank 50g of nickel nitrate hexahydrate and 1.6g of phosphoric acid with a concentration of 98% were dissolved and mixed evenly, and then added to the above solution with a pore volume of 1.109mL / g and a specific surface area of 343m 2 / g, dry basis is 70% macroporous pseudo-boehmite 42.9g and Y-type molecular sieve (SiO 2 / Al 2 o 3The molar ratio is 12.5) 5g, after stirring evenly, add curing agent urea, add deionized water after the urea is completely dissolved, make the sum of aluminum oxide, silicon dioxide, molecular sieve, nickel oxide and phosphorus pentoxide in the preparation tank The concentration was 33%, and the fluidity of the slurry was maintained.

[0042] The above fluid slurry is spray-dried in a spr...

Embodiment 2

[0046] Add 100 g of water glass with a silicon oxide content of 35% in the preparation tank, start the stirring device, and then slowly add a 62% nitric acid solution to make the pH of the acidified water glass solution 2.5, mix well and add to the preparation tank 50g of nickel nitrate hexahydrate and 1.6g of phosphoric acid with a concentration of 98% were dissolved and mixed evenly, and then added to the above solution with a pore volume of 1.109mL / g and a specific surface area of 343m 2 / g, dry basis is 70% macroporous pseudo-boehmite 42.9g and Y-type molecular sieve (SiO 2 / Al 2 o 3 The mol ratio is 12.5) 5g, after stirring evenly, add curing agent hexamethylenetetraammonium, add deionized water after the urea is fully dissolved, make the alumina, silicon dioxide, molecular sieve, nickel oxide and five The concentration of the sum of phosphorus oxides is 33%, and it is kept as a slurry with certain fluidity.

[0047] The above-mentioned slurry with certain fluidity i...

Embodiment 3

[0051] Add 100 g of water glass with a silicon oxide content of 35% in the preparation tank, start the stirring device, and then slowly add a 62% nitric acid solution to make the pH of the acidified water glass solution 2.5, mix well and add to the preparation tank 50g of nickel nitrate hexahydrate and 1.6g of phosphoric acid with a concentration of 98% were dissolved and mixed evenly, and then added to the above solution with a pore volume of 1.109mL / g and a specific surface area of 343m 2 / g, dry basis is 70% macroporous pseudo-boehmite 42.9g and Y-type molecular sieve (SiO 2 / Al 2 o 3 The molar ratio is 12.5) 5g, after stirring evenly, add curing agent urea, add deionized water after the urea is completely dissolved, make the sum of aluminum oxide, silicon dioxide, molecular sieve, nickel oxide and phosphorus pentoxide in the preparation tank The concentration was 33%, and it was kept as a slurry with certain fluidity.

[0052] The above-mentioned slurry with certain f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com