Colorful powdered ink used for static development and preparation method thereof

A color toner, electrostatic technology, applied in the direction of developer, electrography, optics, etc., can solve the problems of inability to improve image density, poor colorant dispersibility, low toner particle resistance, etc., to achieve narrow particle distribution, chargeability Good, good spherical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

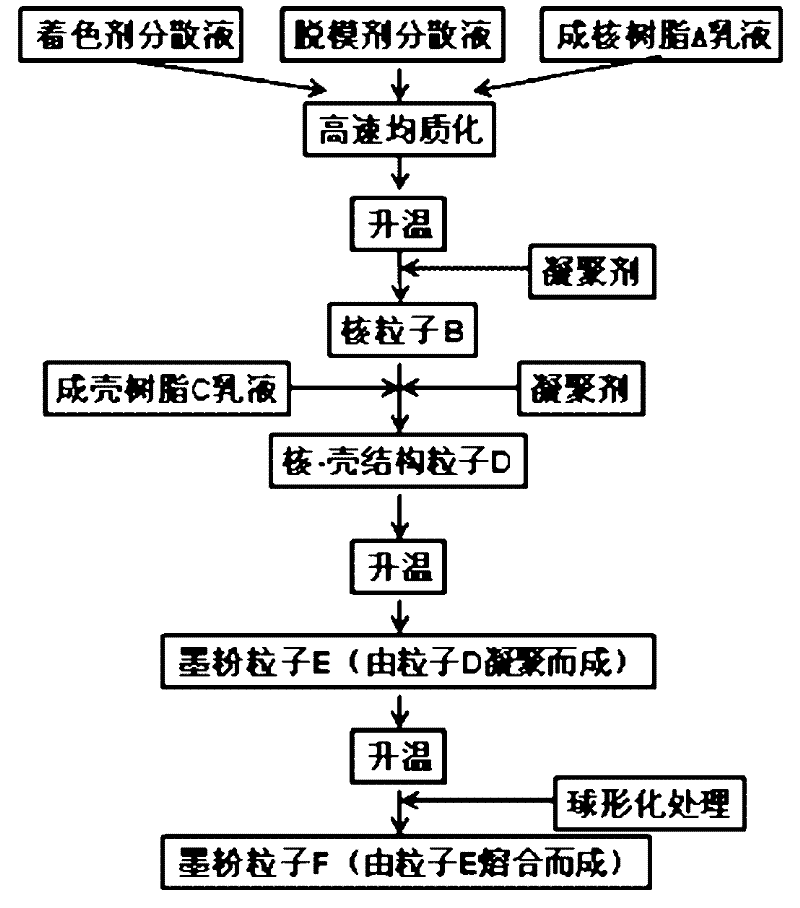

Method used

Image

Examples

Embodiment 1

[0038] 1) Preparation of resin emulsion A

[0039] Add 270g of deionized water, 3.6g of sodium lauryl sulfate, 4.5g of OP-10, 232g of styrene, and n-butyl acrylate to the first reactor equipped with a water bath (40°C) and a stirring device (300rpm). 62g, 2.6g n-dodecyl mercaptan, to form a monomer emulsion; into another second reactor equipped with a water bath (80°C) and a stirring device (400rpm), 300g deionized water and 1.8 sodium lauryl sulfate were added g. Sodium bicarbonate 0.194g. Under the condition of nitrogen purging, 80g of the monomer emulsion emulsified in the first reactor was added to the second reactor, and the initiator solution (2.0g ammonium persulfate, 61g deionized water) was added dropwise at the same time. After 30 minutes, Then, the remaining monomer emulsion in the first reactor was slowly added dropwise to the second reactor, and the remaining monomer emulsion was dropped after the completion of the dripping and kept for 2 hours and dropped to room t...

Embodiment 2

[0049] Preparation of black toner particles by emulsion aggregation method

[0050] The preparation process is the same as 1)-4) in Example 1, except that the mass ratio of resin emulsion A and B in step 5) is 1, and the results of preparing toner particles are shown in Table 1.

Embodiment 3

[0052] Preparation of black toner particles by emulsion aggregation method

[0053] The preparation process is the same as 1)-4) in Example 1, except that the mass ratio of resin emulsion A and B in step 5) is 2, and the result of preparing toner particles is shown in the following table.

[0054] Comparison of results of Examples 1-3

[0055] Item

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com