Preparation method of high-performance sintering permanent magnetic ferrite magnet

A permanent ferrite, high-performance technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of high cost and low efficiency, and achieve low cost, short milling time, and narrow particle size distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

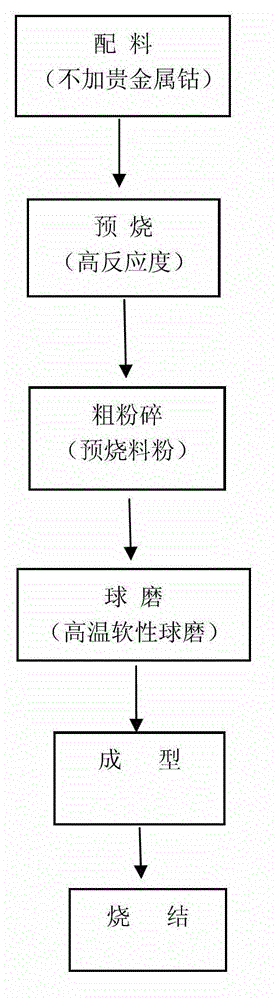

Method used

Image

Examples

Embodiment 1

[0045] The raw material requirements and corresponding weights for the batching process are as follows:

[0046] (1) Iron oxide (Fe 2 o 3 ) powder (purity ≥ 99.0wt%, original average particle size: 0.9-1.0μm), weight 26280Kg;

[0047] (2) Calcium carbonate (CaCO 3 ) powder, (purity ≥ 98.5wt%, original average particle size of particles: 1.0-2.0μm), weight 630Kg

[0048] (3) Strontium carbonate (SrCO 3 ) powder, (purity ≥ 98.5wt%, original average particle size of particles: 1.0-2.0μm), weight 2010Kg;

[0049] (4) Barium carbonate (BaCO 3 ) powder, (purity ≥ 98.5wt%, original average particle size of particles: 1.0-2.0μm), weight 120Kg;

[0050] (5) Lanthanum oxide (La 2 o 3 ) powder (purity ≥ 99.0wt%, original average particle size of particles: 1.0-2.0μm), weight 960Kg;

[0051] Add the above-mentioned weighed raw materials into a 50 cubic meter mixing tank, add 90kg of sintering aid SiO2 powder (purity ≥ 99.0wt%, original average particle size of particles: 20-30.0μ...

Embodiment 2

[0058] Embodiment 2 (secondary addition cobalt amount different ratio test)

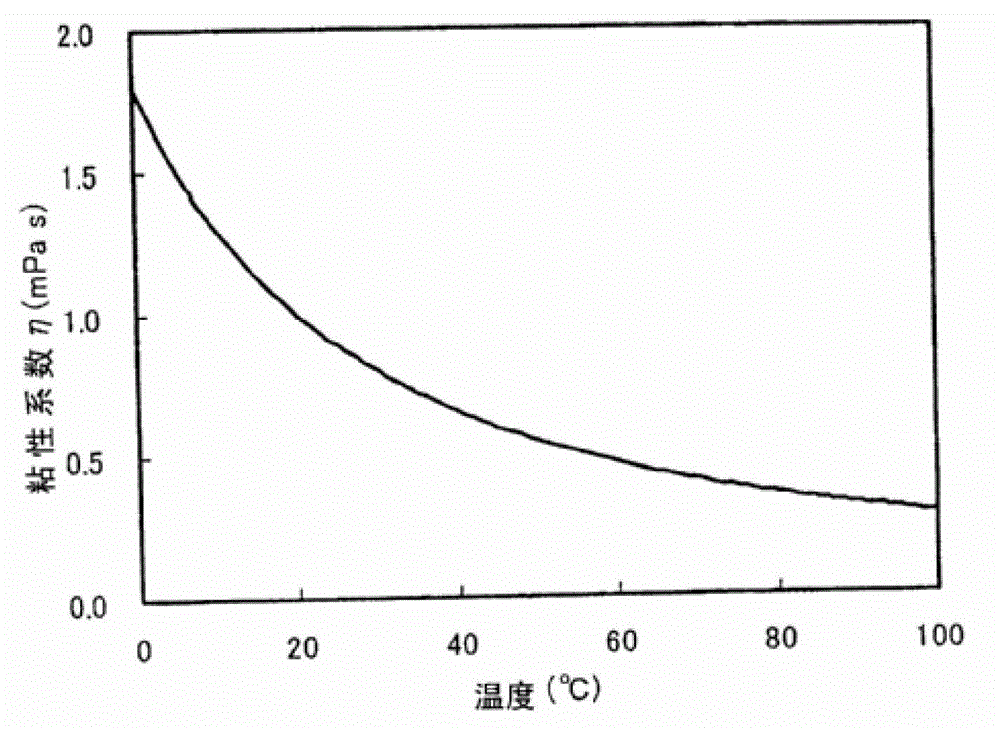

[0059] Select 1300kg of calcined powder same as Example 1, add secondary additives according to three different cobalt amounts, add 1300 liters of 90-100 ℃ hot water for ball milling, the ball mill is not cooled during ball milling, keep the slurry temperature at 100 Above ℃, ball milling for 12 hours, the average particle size of the slurry after ball milling is 0.92 μm.

[0060] After ball milling, cool down naturally, wait for the temperature of the slurry to reach below 50°C, adjust the water content of the forming slurry, adjust the concentration of the slurry to 65%, and then form it, and apply an orientation magnetic field with a magnetic field strength of 600 kA / m in the pressing direction , at a molding pressure of 0.4ton / cm 3 Perform compression molding. The obtained molded body was a cylinder with a diameter of 40 mm and a height of 13 mm.

[0061] The molded body is heat-treated at a t...

Embodiment 3

[0065] Embodiment 3 (comparative test of ball milling conditions)

[0066] Select calcined powder 1300kg identical with embodiment 1, add 1.0wt% lanthanum oxide (La 2 o 3 ) powder (purity ≥ 99.0wt%, original average particle size of particles: 1.0-2.0μm), 1.0wt% Co3O4 powder (purity ≥ 98.5wt%, original average particle size of particles: 1.0-2.0μm), 0.19wt% H 3 BO 3 Powder (purity ≥ 99.0wt%), 0.5wt% Cr2O3 powder (purity ≥ 99.0wt%, original average particle size of particles: 3.0-5.0μm), ball milled according to four different ball milling conditions.

[0067] The ball milling condition of embodiment 3-1 is: add 1300 liters of hot water at 90-100 ℃, the ball mill is not cooled during ball milling, and the ball milling time is 12 hours; the ball milling condition of embodiment 3-2 is: add 1300 liters of 10-35 ℃ water, and The ball mill needs to be cooled with cooling water, and the ball milling time is 12 hours; the ball milling condition of embodiment 3-3 is: add 1950 liters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com