Three-dimensional modeling method of surface morphology of parallel diamond grinding wheel

A diamond grinding wheel and surface topography technology, applied in 3D modeling, image data processing, special data processing applications, etc., can solve the problem that the characterization parameters do not form a unified standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

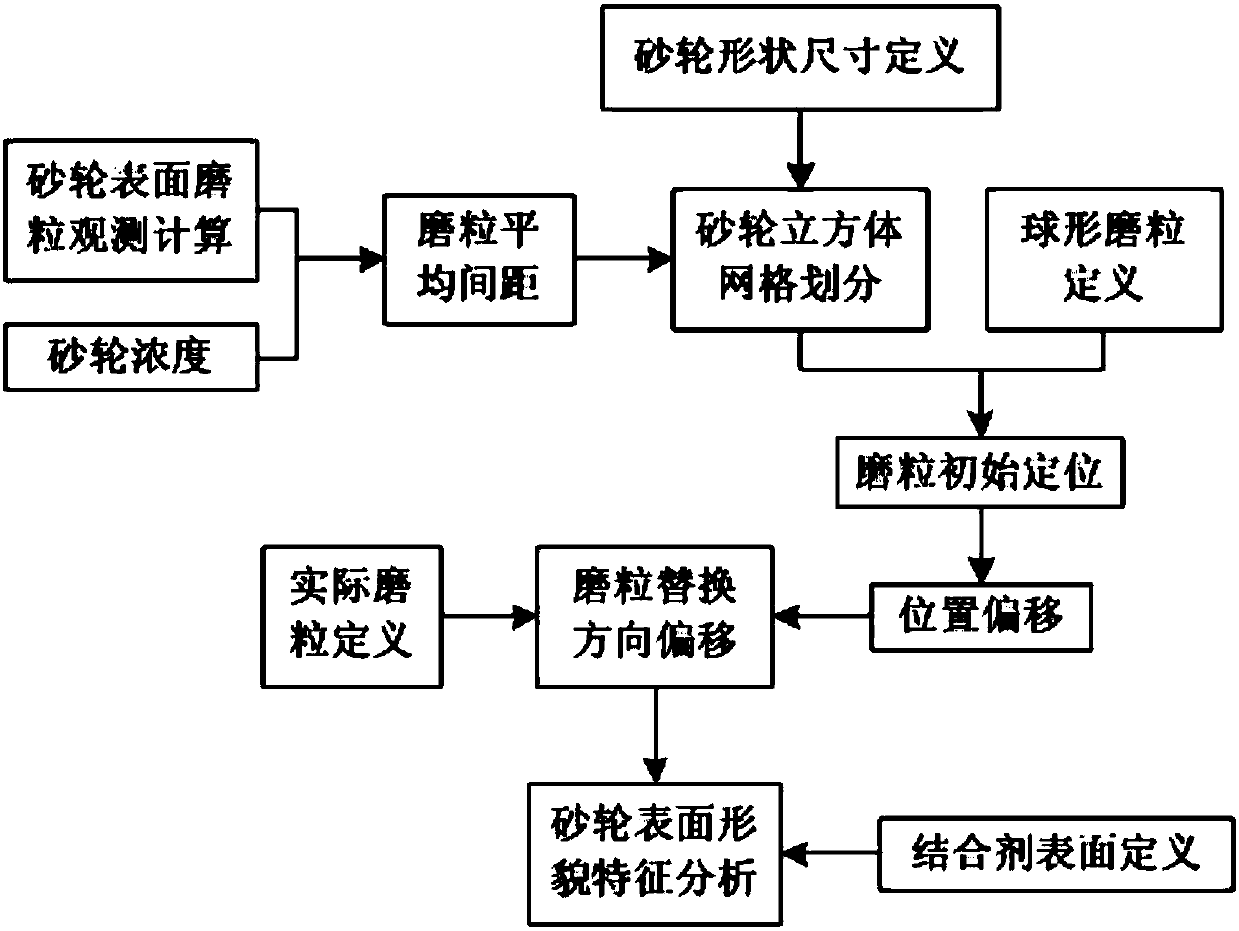

[0067] Such as figure 1 As shown, a three-dimensional modeling method for the surface topography of a parallel diamond grinding wheel includes the following steps:

[0068] Step 1: Define the parallel diamond grinding wheel model and abrasive grain model.

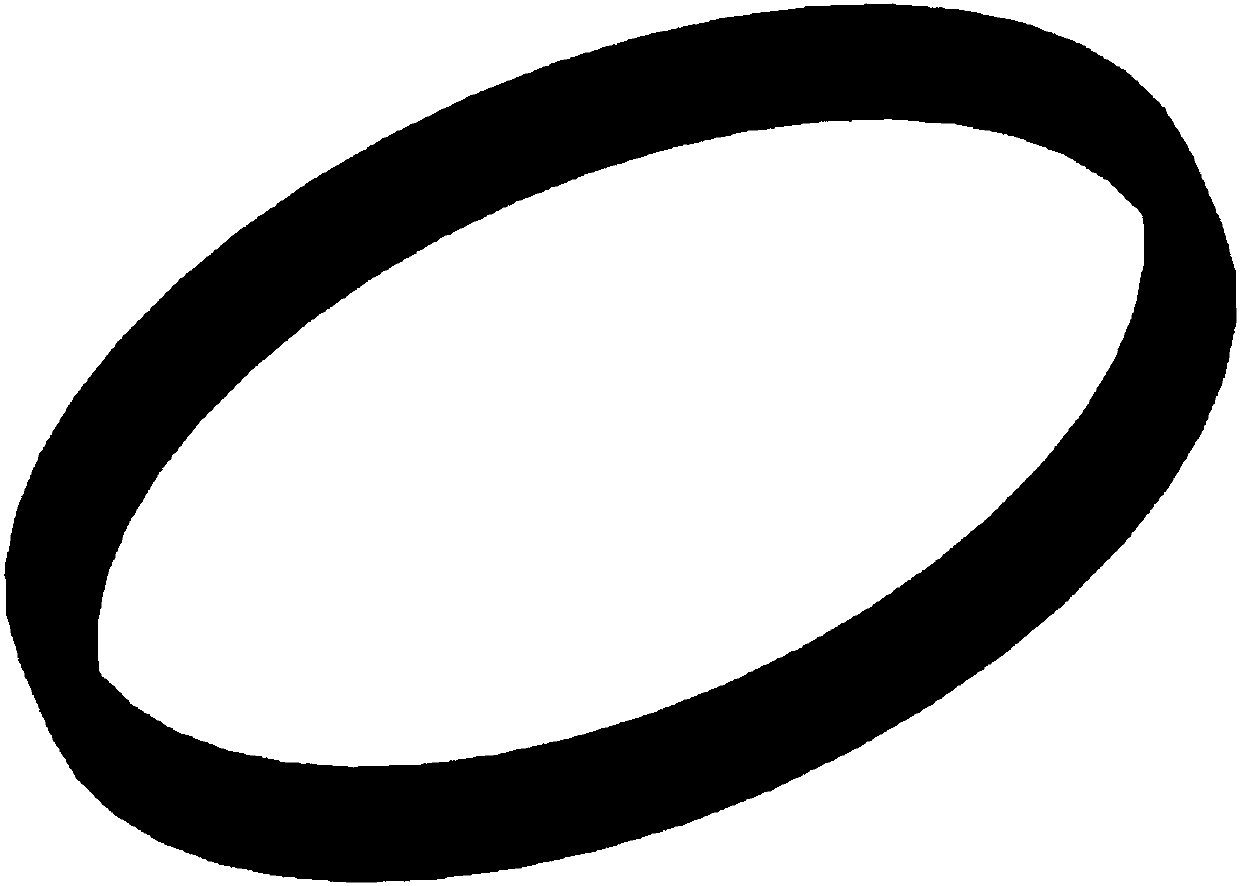

[0069] Grinding wheel model: the selected diamond grinding wheel of the present invention is a parallel grinding wheel, the inner diameter of the grinding wheel is 32mm, the outer diameter is 200mm, the thickness is 15mm, and the thickness of the working layer (the layer where the abrasive grains and bonding agent are located) is 10mm. The surface topography modeling of the grinding wheel mainly analyzes the surface topography of the working layer, so the simulation shape of the grinding wheel is determined to be a ring with an inner diameter of 180mm, an outer diameter of 200mm, and a thickness of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com