Online monitoring method for electrolytic grinding process

A process, electrolytic grinding technology, applied in the field of monitoring, to achieve good surface morphology, improve accuracy, and facilitate online control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

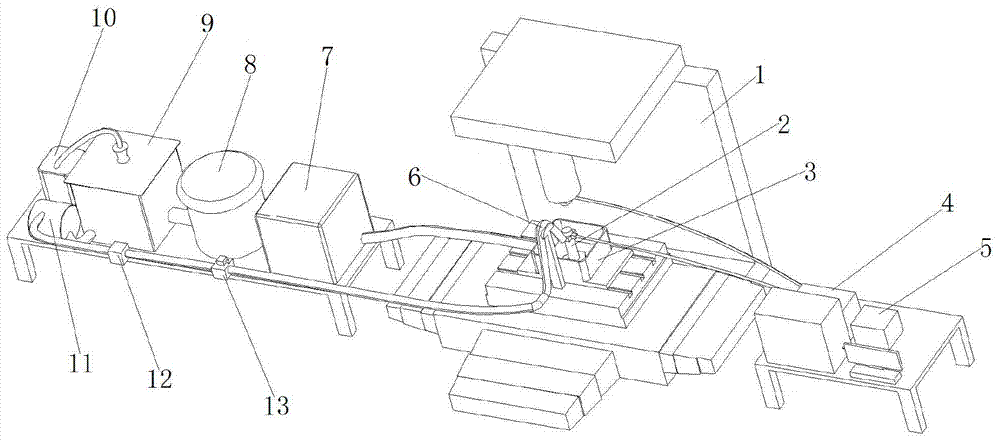

[0023] In order to further understand the content of the present invention, the present invention is described in detail.

[0024] A method for on-line monitoring of the electrolytic grinding process of the present invention, the steps are:

[0025] (1) Collect a certain amount of electrolyte solution with particles and dilute it;

[0026] (2) analyze the particles in the diluted electrolyte in step (1):

[0027] 1) Use the CSI particle analyzer to analyze the electrolyte containing particles, and the particle number and size distribution can be obtained;

[0028] 2) First use ferrographic technology to make ferrographic slices, and then use ferrographic microscope with image acquisition system to analyze and study the ferrographic slices to obtain the characteristics of particle color, composition, shape, size and type;

[0029] 3) First use the filter spectrum technology to make the filter spectrum, and then use the laser confocal microscope to analyze and study the filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com