A Method of Applying Ultrasonic Wave Energy to Suspended Matter to Accelerate Settling

An ultrasonic and suspended solids technology, applied in the direction of mechanical oscillation water/sewage treatment, etc., can solve the problems of large surface area and volume, long time required, etc., to achieve the effect of no maintenance cost, easy online control, and reduced floor space and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

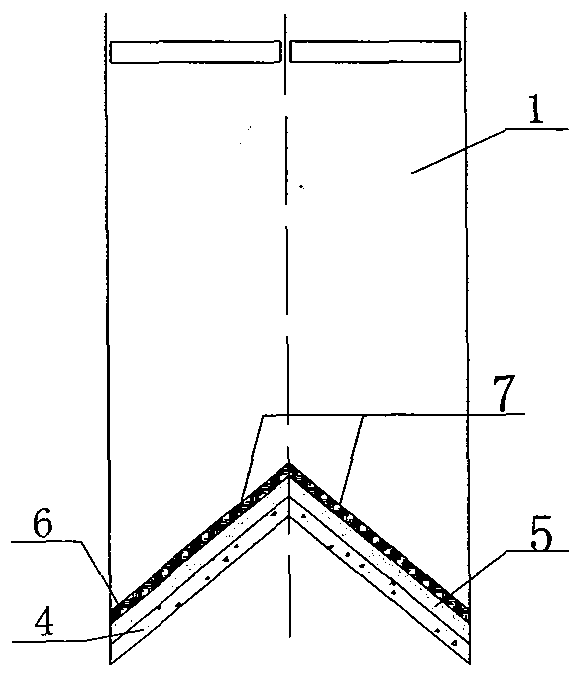

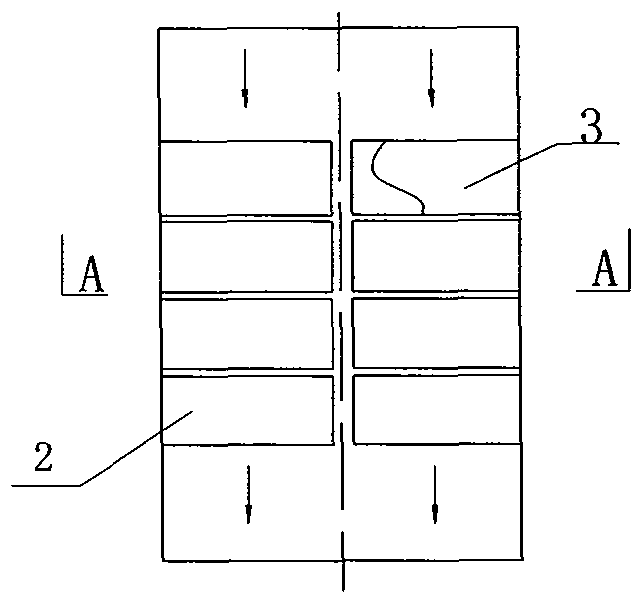

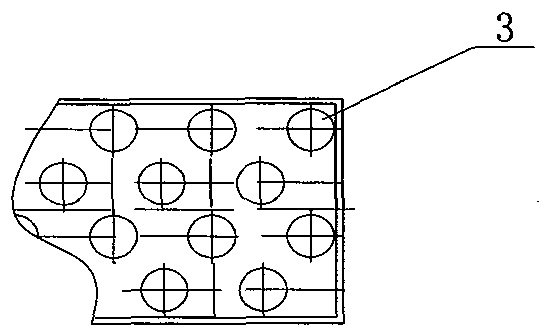

[0034] Arrange the vibrating plate 2 with the built-in ultrasonic electroacoustic transducer in the frame of the water surface of the sedimentation tank 1. The ultrasonic electroacoustic transducers 3 in the vibrating plate are arranged in rows and columns, and are grouped and connected in parallel. The arrows indicate the water inlet and outlet direction. When the water to be settled enters the sedimentation tank from the water inlet direction, the high-frequency current frequency modulation device 8 supplies the high-frequency current to the electro-acoustic converter 3, and controls and adjusts the frequency of its high-frequency current so as to control the electro-acoustic transducer to make it Accelerated settling works best. When the ultrasonic waves reach the bottom of the pool, most of the wave energy is absorbed by three layers of materials of different materials, which are the upper layer of polyester fiber 6, the middle layer of porous polyester foam plastic 5, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com