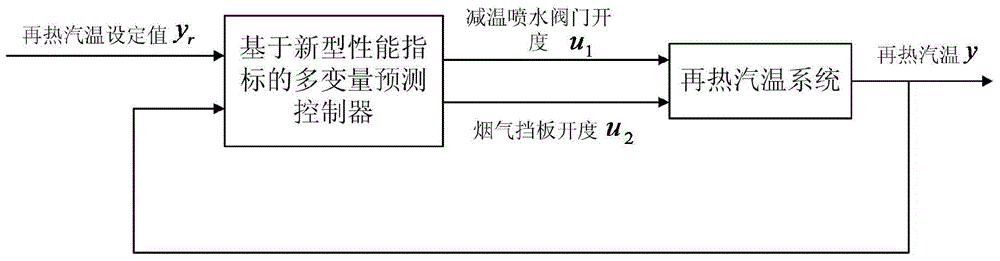

Method for realizing reheat steam temperature multivariable coordinate predictive control through performance indexes

A reheat steam temperature and predictive control technology, applied in non-electric variable control, temperature control, general control system, etc., can solve the problems of affecting unit economy, large amount of calculation, lack of effective control parameters, control system performance adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

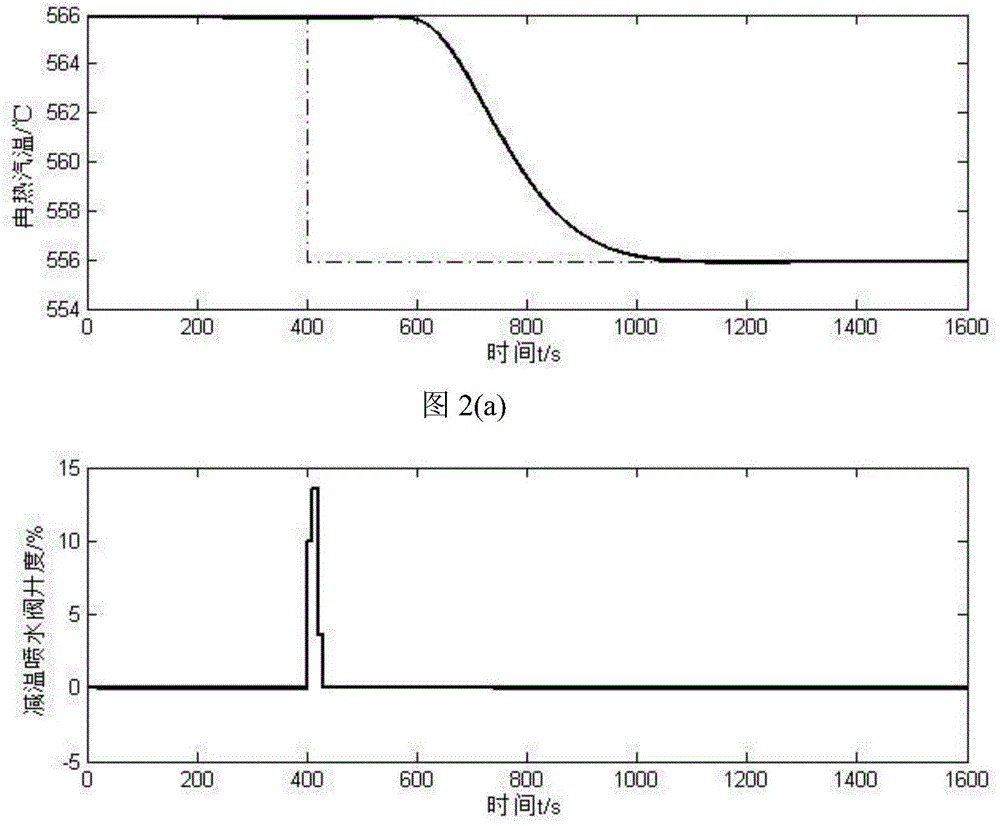

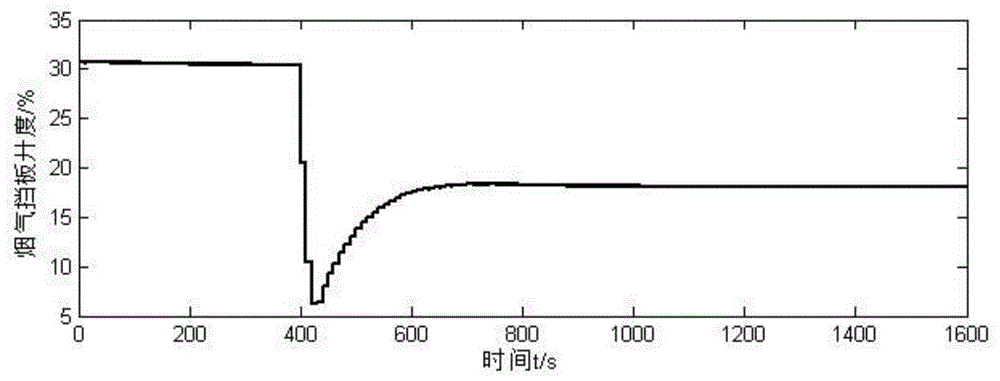

[0022] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

[0023] Step 1: Obtain the step response model of the reheat steam temperature object. Under steady-state conditions, conduct open-loop step response tests of the opening of the desuperheating spray valve and the opening of the flue gas baffle to obtain the system response Data, using the step response model identification method, identify the transfer function model of the desuperheating spray valve opening - reheat steam temperature and flue gas baffle opening - reheat steam temperature;

[0024] In this embodiment, the outlet steam temperature y (°C) of the reheater has a great influence on the opening degree u of the desuperheating spray valve 1 (%) The transfer function of the response is:

[0025] G 1 ( s ) = - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com