Micro intelligent factory experiment and research platform

A smart and factory technology, applied in the direction of comprehensive factory control, comprehensive factory control, instruments, etc., can solve the problems of low automation and complexity, and achieve the effects of thorough perception, in-depth intelligence, and extensive interconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The invention provides a micro smart factory experiment and research platform. The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

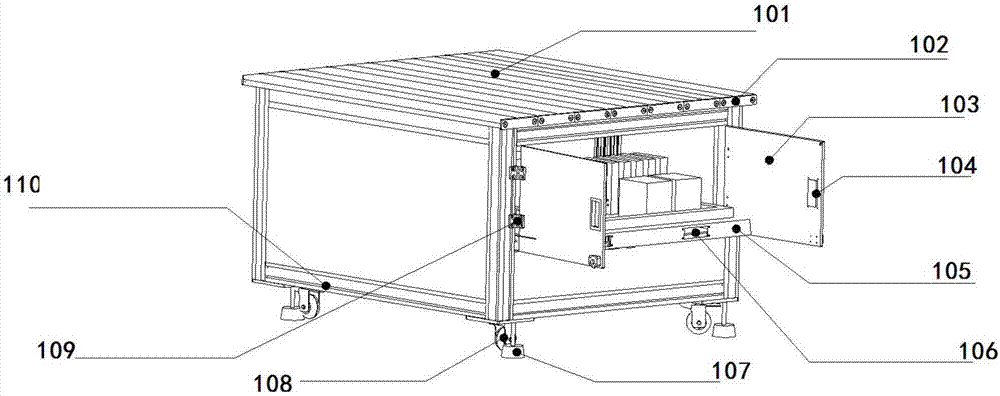

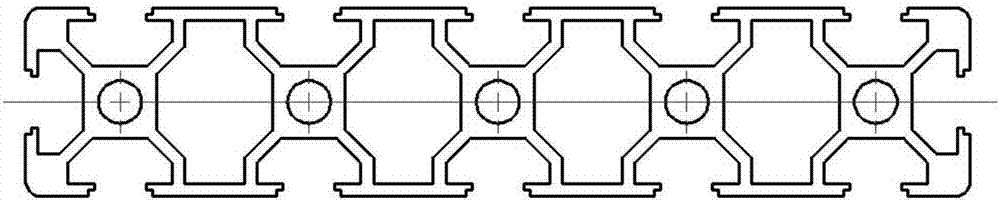

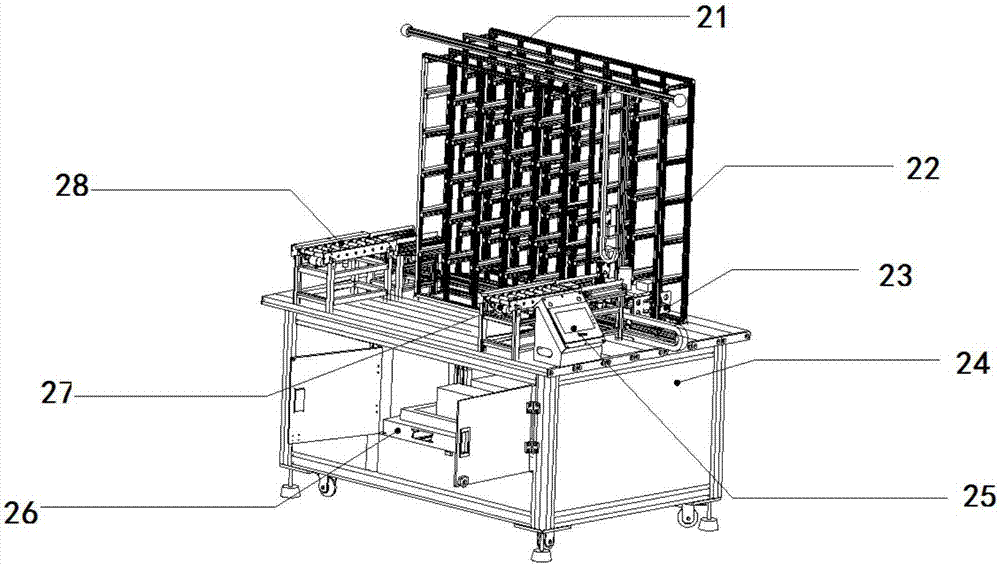

[0036] This proposal discloses a micro-smart factory experiment and research platform, including a processing line system, a three-dimensional warehouse system, a sorting system, a manual assembly system, a transportation and distribution system, and an AGV feeding system. The sorting system, the manual assembly system, and the transportation and distribution system are respectively connected to the AGV feeding system; It includes a countertop and a cabinet set below the countertop, and a circuit control board is arranged inside the cabinet; the processing line system, three-dimensional warehouse system, sorting system, manual assembly system, and conveying and distribution system communicate through OPC The protocol is electrically connected to each other; the processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com