A workshop intelligent conveying system and its conveying method

An intelligent conveying and workshop technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of high labor intensity, low intelligence level, and large safety hazards for workers, so as to improve work efficiency and safety, The effect of improving work efficiency and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical means, goals and effects of the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

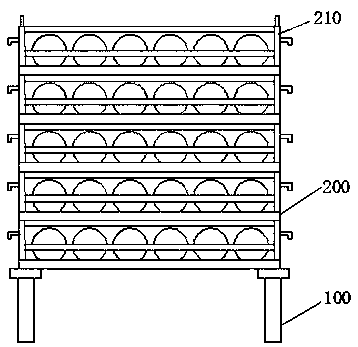

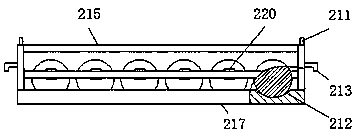

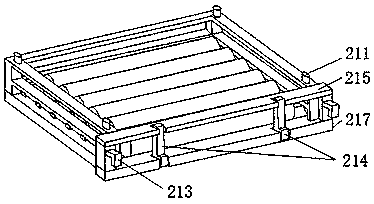

[0043] A workshop intelligent conveying system, such as figure 1 As shown, it includes a placement rack 100; the set position above the placement rack 100 can place a storage rack 200, and the storage rack 200 includes several storage layers 210, such as figure 2 , image 3 , Figure 4 As shown, the storage layer 210 includes a bottom plate 217, a plurality of positioning grooves 212 are opened on the upper plane of the bottom plate 217, a frame 215 is arranged on the bottom plate 217, lifting ears 213 are arranged on the outside of the frame 215, and the frame 215 The top is provided with an upper positioning part 211, preferably, the upper positioning part 211 is arranged on the four corners of the frame 215; the bottom of the bottom plate 217 and matched with the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com